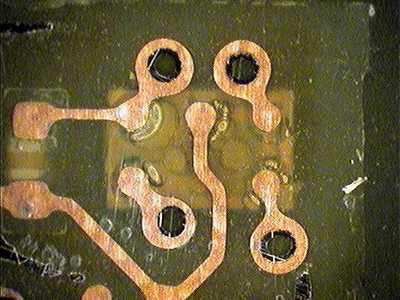

Most of us think instantly of cross-sectioning when sample examination is mentioned. ‘Flat’ or ‘lap’ sectioning can be a great alternative in certain situations, and is usually a good supplement to cross-section views. Flat or lap sections are essentially cross-sections that are polished in the same plane as a BGA or die, and are used to view all interconnections in relationship to each-other. As shown in the picture here, a flat section can also reveal oddly shaped solder joints that may have gone unnoticed otherwise. I like to use this technique when I suspect problems with solder mask openings. Often, you can clearly see when solder wets a trace instead of being contained on a pad properly. Flat sectioning is a notable technique, and perhaps another trick you can use to learn more about solder joint geometry in your own application.