Phil Zarrow: This is for anyone considering halogen-free solder paste or flux, including the challenges associated with their usage.

Brook, when I switch to a halogen-free solder paste, what are some of the trade-offs I can expect?

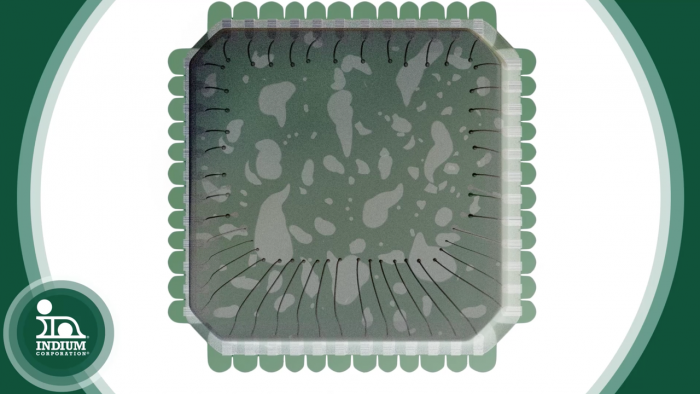

Brook Sandy: With a halogen-free solder paste, the main difference is that the activator package is changed. There might be more of a propensity for these fluxes to be exhausted during reflow. It's important, when you're choosing a paste in a reflow profile, to make sure the profile isn't too long and hot, otherwise, you're likely to see reflow defects that are caused by oxidations, such as graping or excessive voiding.

Phil Zarrow: What about with wave solder?

Brook Sandy: With wave soldering fluxes, you might run into the same challenges, where there might be a propensity to exhaust the flux with excessive preheat times or really high temperatures. If you're running into that kind of an issue, you'll see insufficient hole fill or poor wetting in the barrels.

Phil Zarrow: Where can I find more information about halogen-free solder pastes?

Brook Sandy: Visit our halogen-free page at www.indium.com or you can email me directly at bsandy@indium.com.

Phil Zarrow: Brook, thank you very much.

Keywords: Phil Zarrow, Brook Sandy, halogen-free solder, indium corporation, voiding, wave solder, reflow profile