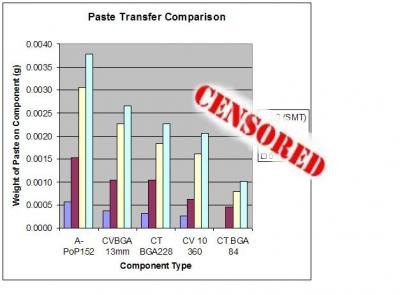

What’s the difference between Package-on-Package (PoP) / BGA rework solder paste, and solder paste designed for SMT? Solder paste for dipping applications is designed to transfer more solder based on its rheological characteristics. In the chart shown here, a typical SMT paste is compared to 3 next generation dipping pastes. Although the names cannot be released right now, all PoP/rework pastes transferred over 100% more paste to the solder joint area. (Hint: you can probably break me down relatively easily if you have me on the phone. For the whole story call me at (315) 853-4900)

This added solder volume helps ensure that more solder is available during joint formation to compensate for component warpage. During rework, increased solder volume replaces solder that has been scavenged during the component removal process. Either way, more solder volume relates to a more robust solder joint.