Often times solder defects such as spattering, voiding, slumping/bridging, and tombstoning can be remedied just by adjusting the reflow profile. For this reason it is important to understand the different stages of a reflow profile and how they can affect the end solder joint.

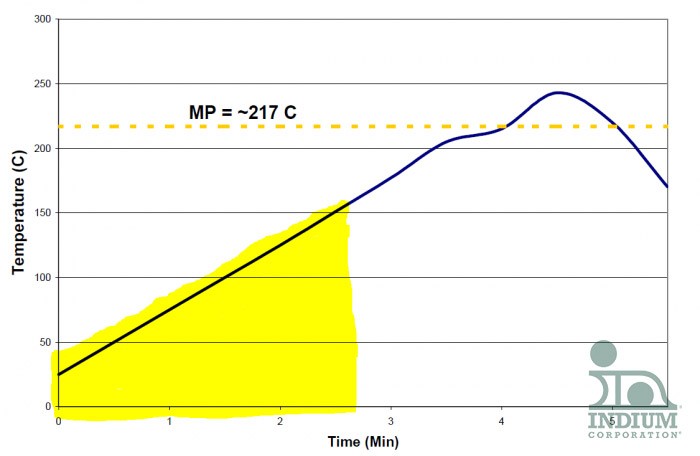

The very beginning of the reflow process, during the first few oven zones, focuses on drying out the solvents in the solder paste, getting ready for the activators in the flux to begin removing oxides. It is crucial that this is a slow and controlled ramp-up; if the paste is heated up too quickly the flux will boil and start to spatter solder all over the board. Another defect you may see from a too fast ramp-up is slumping of the solder paste, which can lead to bridging. Heating the paste too much before all the solvents evaporate will cause the viscosity to decrease which will then lead to solder slumping. A recommended ramp rate would be between 0.75°C/s and 2°C/s.

Subsequent blog posts will talk about other aspects of teh reflow profile.