The first two weeks of my internship at Indium Corporation are complete and I cannot believe how quickly time is moving.

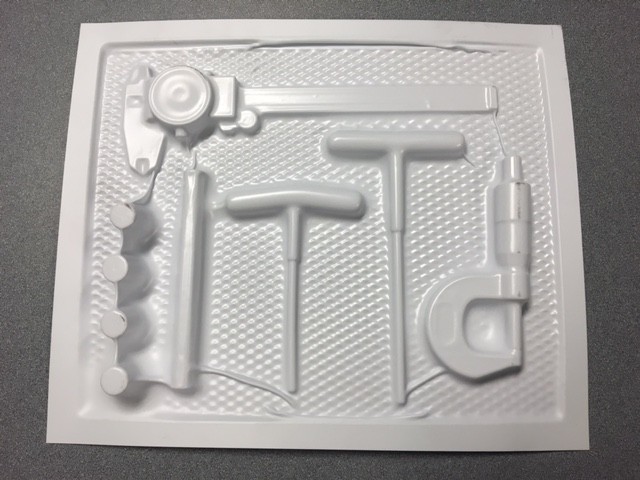

My primary project is to develop and design a process for thermoformed packaging for some of the products that Indium Corporation produces. The idea behind thermoforming is to soften a sheet a plastic and form that sheet to a specific object through the use of a vacuum.

I will be involved in developing flow charts, procedures, project planning, and much more. I already have been exposed to so many different processes and concepts, most of which are not introduced in college, which is why I am here at Indium Corporation. Yes, sometimes it may be difficult to grasp the concept or idea at first, but I am here to learn. This is what motivates me to get my work done. I thoroughly enjoy the challenge and how it makes me think outside the box at times.

The tool and die department is where I will primarily spend my time in the future. Along with thermoforming, I am also exposed to various types of machinery. Developing a facility with machinery is an important part of becoming a Mechanical Engineer. The most important part is understanding how these machines operate and all the different terminology that is used. These machines include various mills to CNC machines. The machines are used to create the different tools and dies that Indium Corporation then uses to produce various products. These tools are hand-crafted by specialized individuals who are assigned specific challenging tasks each and every day. Some parts have tolerances as fine as 0.005” of an inch; it definitely takes talent to make these tools.

For me it is pretty cool to see how everything works and operates in the manufacturing setting. Looking at the two weeks I have spent here at Indium Corporation, I know I am gaining valuable experience.