Related Bar Solder Blog Articles

Solder Reflow Equipment Options

Most of our customers use whatever heating method they already have, unless they are starting from scratch or unless there is a reason their existing reflow equipment will not work well for a new...

Read More物流管理---工业界的“自动售卖机”Industrial Vending Machine In Electronics Assembly

最近有一个客户向我们展示了他们公司新采用的“自动售卖机”库存管理系统(industrial vending machine),真是大开眼界。在此和大家分享一下。 请看下面的图片。 这个自动售卖机和我们平时看见卖零食的机器表面上没什么大区别,最多是可以在机器旁边衍生多些大格子储存更多的货品。客户的采购员自豪的向我们介绍了采用这套系统后带来的好处(当然,所有好处都是围绕降低成本和容易系统管理) 免费机器,一年6%的rebate 拿到物品开始算钱: 员工凭自己的门卡在机器上取到需要的货品后,供应商才开始计算物品单价。月结。换言之,在机器上的所有物品,只要客户没有从机器中取出,供应商都不收客户钱。 网络监控管理: 采购人员可以在机器上设置好,对所有物品的取出,谁取出,每次、每天取出多少,都可以通过机器变好程序,设置好。这样管理,知道谁拿了什么,减少浪费。一个很简单的例子:几种擦拭机器的不同牌子的纸,表面上看都一模一样,其实有一种是5分钱一张,有一种是1.5元一张。 1.5元一张的确实特别好用,某些特殊机器就是要用这种贵纸才能擦干净。采购员买了两种都放在车间。但是车间人员不知道差别,大家都随便取用,有时候用贵的纸什么都擦,甚至擦鼻子:-) 现在有了vending machine, 就可以控制只有擦贵机器的人才可以限量取到贵的纸。 采购人员可以在网上实时监控,知道每种货品每个时间段的用量,谁用了、用了多少,机器中还剩下多少等。以前,很多公司的采购人员只能通过预算购买下一次的货品,但是他们对现存货品剩下量的多少,没有实时资讯,所以造成了很多取货现象。 通过网络在线订货购买 看到介绍后我们都很感慨,觉得做这个vending machine的公司十分有创新性。而且那么优惠的条件(免费机器,“0”库存,年底的rebate), 这些都是等于把现金都压在了客户那里。这个公司一定要有雄厚的实力和足够多和大的客户,才能利用规模相应(economic scales),不然毛利这么低,怎么赚钱…… 我们还谈到了焊接产品(soldering materials)。目前,客户准备把焊锡棒(solder bars)和锡线 (solder wires)放在vending machine中管理,但是焊锡膏、焊锡球、助焊剂等(solder paste, solder spheres, wave fluxs)不能放, 因为solder paste...

Read MoreHappy Birthday Indium Corporation!

March 13th is the 78th anniversary of the founding of Indium Corporation. Dr. William S. Murray, J. Robert Dyer JR, and Daniel Gray combined to create a company that was, in 1934, on...

Read MorePatty Presents Her Electronics Assembly Copy Exactly Strategy

Folks, Patty is getting ready for her meeting on “Copy Exactly” with Mike Madigan….... It was after 6:30 PM and Patty was just arriving home. Since Patty was working late, Rob had agreed to make his signature dish, crispy macaroni and cheese. Patty and Pete had just finished their project...

Read MoreRecycling Solder Dross

Anyone who has used wave soldering to assemble PCBs knows about that chunky layer of metal that collects on the smooth surface of the molten solder. This is solder dross; it is composed of...

Read MoreFeatures & Benefits

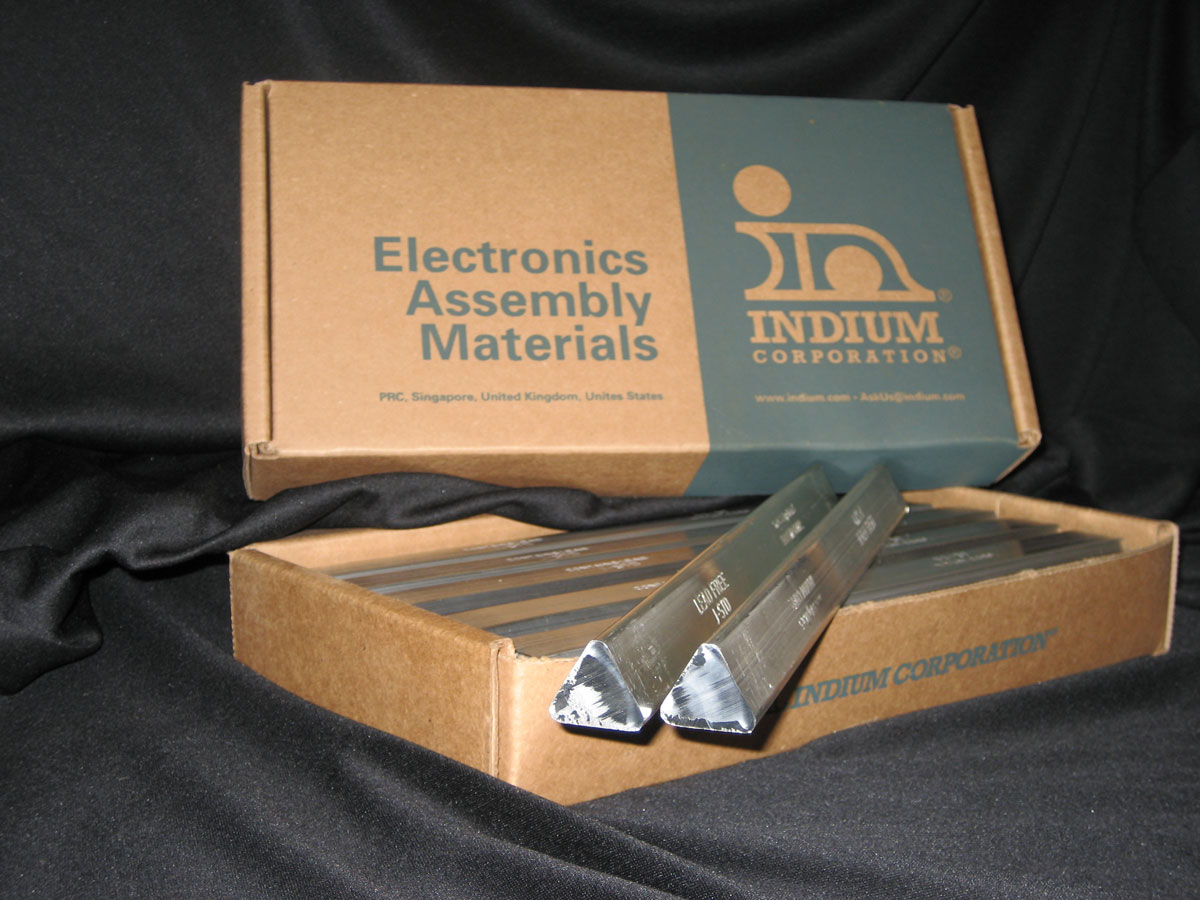

Indium Corporation bar solder alloy composition and purity meets, or exceeds, the requirements of ASTM B32, IPC J-STD-006, and JIS Z 3282, as well as all other similar industry and customer specifications.

Bar Solder Chips are also available and are commonly used to fill smaller solder pots or to quicken the melting of solder in a new solder pot. The greater surface area of the chips allows for better heat transfer between the solder pot and the metal.

Featured Bar Solder Products

| Alloy | Type and Application | Melting Temp. | Specific Gravity |

Bar Cross- Section |

Packaging |

|---|---|---|---|---|---|

| 63Sn/37Pb | Most common tin-lead alloy for though-hole wave soldering | 183°C (361°F) | 8.39 | Trapezoidal | 15 bars - 25 lb. box |

| 60Sn/40Pb | Most common tin-lead alloy for single-sided wave soldering | 183°-191°C (361°F-376°F) | 8.50 | Trapezoidal | 15 bars - 25 lb. box |

| SAC305 (96.5Sn/3.0Ag/0.5Cu) | Most common silver-containing Pb-Free alloy for wave solder | 217°-220°C (423°F-428°F) | 7.35 | Triangular | 18 bars - 25 lb. box |

| SAC0307 (99.0Sn/0.3Ag/0.7Cu) | Lower cost silver-containing Pb-Free alloy for wave solder | 217°-227°C (423°F-441°F) | 7.31 | Triangular | 18 bars - 25 lb. box |

| Sn995 (99.5Sn/0.5Cu/Co) | Cobalt-doped, silver-free, Pb-Free wave solder alloy | 227°C (441°F) | 7.32 | Triangular | 18 bars - 25 lb. box |

| Sn992 (99.3Sn/0.5Cu/0.3Bi/Co) | Bismuth-containing, cobalt-doped, silver-free, Pb-Free wave solder alloy | 227°C (441°F) | 7.31 | Triangular | 18 bars - 25 lb. box |

| Indalloy® 291 (99.25Sn/0.7Cu/0.05Ni/Ge) | Low cost, no silver, pb-free wave solder alloy | 227°C (441°F) | 7.4 | Triangular | 18 bars - 25 lb. box |

Alloys for dip tinning and other applications: 50Sn/50Pb, 40Sn/60Pb, 30Sn/70Pb, 10Sn/90Pb, 5Sn/95Pb, 96.5Sn/3.5Ag, 95Sn/5Sb, SAC105, and others upon request