Related IGBT and Engine Controls Blog Articles

Digital and Physical: Thermal Twins for Developing Thermal Management Solutions

As we all know, finding thermal management solutions is becoming an increasingly critical but also an ever more challenging issue for the semiconductor industry...

Read MoreThermal Test Chips (TTCs) for Advanced Semiconductor Packaging

Thermal management is becoming an ever more critical challenge for semiconductor devices, as the functional density and power density increase – especially with advanced packaging. Thermal test chips (TTC) are a critical enabler for developing thermal management solutions for high-power semiconductor devices...

Read MoreSo You Want to be in Manufacturing?

"So You Want to be in Manufacturing?" Blog post for young manufacturing engineers, technicians, and manufacturing operations professionals.

Read More2019 SPIE Photonics West Show

Visit us at SPIE West show at booth #3310 on February 5-7. We look forward to learning more about your applications.

Read MoreAdvanced Technology Workshop on Thermal Management

Indium Corporation presents paper at Advanced Technology Workshop that provdes metal thermal interface materials (TIMs) have a higher insertion rate and higher thermal conductivity than traditional TIMs for burn-in and test.

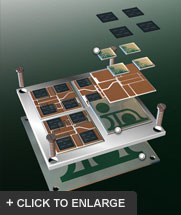

Read MoreIndium Corporation provides solder ribbon and solder preforms for die-attach applications. Tape & reel packaging allows preforms to be advanced and placed with speed and accuracy. Semiconductor-grade ribbon and preforms come in ultra-pure alloys and adaptable packaging, such as tape & reel, custom spools, and cartridge packs, to increase productivity, performance, and efficiencies.

Die-Attach

Indium Corporation manufactures die-attach solder paste for vacuum soldering. Indium Corporation's IGBT die-attach solder paste can be screen printed or stencil printed and is easy to clean.

All material is recyclable and reclaimable.

Materials for Vacuum Soldering

Direct Bonded Copper (DBC) or Substrate-Attach

Indium Corporation's soldering materials for DBC-attach include solder ribbon and solder preforms. Manufactured for purity, they offer low voiding when reflowed in air or vacuum.

InFORMS® were developed to solve the non-planar solder joint issue common in substrate bonding. InFORMS® are reinforced solder alloy fabrications that ensure parallel soldering at a predetermined bondline thickness.

NanoFoil® solders a component in nanoseconds without using a reflow oven. NanoFoil® provides a localized heat source that enables high strength, high conductivity bonding between most combinations of materials. NanoFoil® emits enough energy to solder 25-150+ micron bondlines. In addition, tin-plated NanoFoil has been used to solder gold-plated substrates together without the need for a reflow oven or any plating. For more information, visit www.indium.com/nanofoil/.

Materials for Substrate-Attach

Heat-Sink or Baseplate-Attach

Removing heat from a power module is important for ensuring interconnect reliability. Indium Corporation's Heat-Spring® material is a non-reflow compressible metal pad with a thermal conductivity of 86W/mK. Unlike some of the more typical thermal interface materials, such as thermal grease, Heat-Springs® do not pump out or bake out.

Heat-Springs® can be engineered and optimized for difficult applications and a wide variety of surface conditions. Minimum pressure required is 25-45psi and minimum thickness is 75 microns. Custom packaging includes tape & reel and tray packs. See our application note entitled "Heat-Spring® Metallic Thermal Interface Materials for Application to Infineon Technologies AG PrimePACK IGBT Modules" for information on how Indium Corporation's Heat-Springs® performed in testing against a comparable flat indium shim and two typical silicone-based thermal grease materials.

Liquid metal is another material that can be used as a thermal interface. Liquid metal is RoHS-compliant and has a thermal conductivity of 40W/mK and a contact resistance of virtually zero.

Materials for Heat-Sink or Baseplate-Attach

- Heat-Spring® - Type D (for flat surfaces)

- Liquid metal