Recently, I asked Robert Belvick from Onieda Research Services to share some of his experience cross sectioning microelectronic components.

Robert: Even if you have cross-sectioned before, there is always room for improvement. Here are some more advanced cross-sectioning tips to yield better results.

1) Don’t be afraid to experiment with different polishes or techniques. Some people have used the same thing for so long, they forget that new products are released frequently that may better suite your application.

2) Be sure to keep track of what you’re doing. It’s not uncommon to be distracted by talking to a co-worker and before you know it, you’ve gone through your area of interest!

3) Be sure to switch to fine grit paper before you reach the area of interest, or you may end up going through it trying to clean it up.

4) Don’t hesitate to change your polishing cloth. If some contaminate gets in it, it won’t come out easily. Run your clean fingers over the cloth to check for foreign material before you use it. Even a piece of debris from a sample you just polished can cause scratches in the next one.

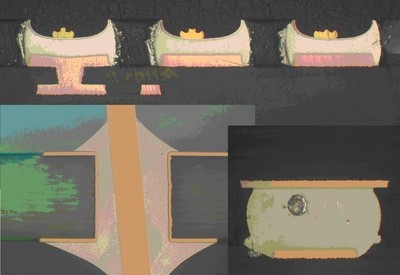

5) Don’t over polish! You can go home and go nuts polishing your chrome rims and they’ll look great, but over polishing a cross-section is quite easy and results in “rounding”. When rounded, some parts of your image may be more in focus than others, because you’ve actually polished away part of the softer material, leaving behind the harder stuff.

6) This is more preference, but I always wear gloves while cross-sectioning. It’s not necessary and some may like to do without, but it’s far too easy to accidentally grind your fingertips if you ask me!