Indium Corporation's Heat-Spring® Thermal Interface Material Enhances Device Performance

October 14, 2015

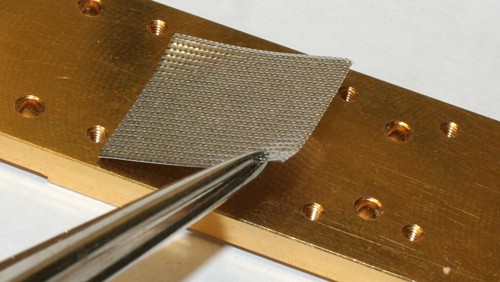

Indium Corporation announces a soft metal alloy thermal interface material (SMA TIM) that offers high and uniform thermal resistance at lower applied stresses in compressed interfaces.

The company’s patented Heat-Spring® SMA TIM reduces thermal resistance and enhances cooling by utilizing two key properties of indium metal: superior thermal conductivity and malleability. Unlike standard thermal interface materials, Heat-Spring offers an extremely long service life as it does not pump out under power cycling, nor does it bake out over time. This combination of high conductance, high surface contact area (due to superior conformance), and low degradation over time produces a superior thermal interface and assures optimized long-term device performance.

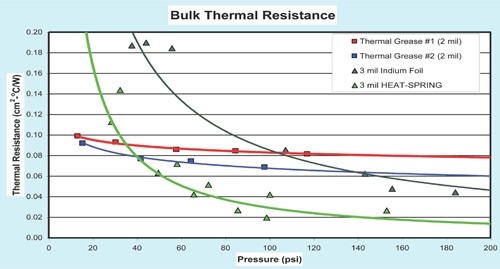

Heat-Spring’s high and uniform thermal conductivity is enhanced further when placed under compression (35 to 100 psi).

Learn more at www.indium.com/heat-spring or by contacting the company at askus@indium.com.

Indium Corporation is a premier materials manufacturer and supplier to the global electronics, semiconductor, thin-film, thermal management, and solar markets. Products include solders and fluxes; brazes; thermal interface materials; sputtering targets; indium, gallium, germanium, and tin metals and inorganic compounds; and NanoFoil®. Founded in 1934, Indium has global technical support and factories located in China, Malaysia, Singapore, South Korea, the United Kingdom, and the USA.

For more information about Indium Corporation, visit www.indium.com or email abrown@indium.com. You can also follow our experts, From One Engineer To Another® (#FOETA), at www.facebook.com/indium or @IndiumCorp.