When you are gluing a picture to a poster board, you don’t want gaps or large spaces without glue, because it would decrease the strength of the overall bond. The picture might bend, bubble, or even just fall off the board. Solder joints are very similar. After reflow (a process where the printed circuit board (PCB) is put through an oven, bringing the solder paste to a temperature above its liquidus, and then cooling) we can observe that the solidified solder is not uniformly distributed throughout the joint. These pockets where no solder is present, are known as voids. There are many different contributing factors that lead to voiding; a major one being the release of gas from a reaction during reflow. During outgassing, some of the gas escapes before the solder solidifies; however, any gas bubbles left form pockets in the joint where no solder is present are the notorious voids.

So, why do we care? Well, some of solder’s major functions include conducting heat, and providing strength and durability. Voiding affects all of these in a negative aspect. Gas is an extremely poor conductor of heat. On a PCB, if a component’s solder joint consists of mostly voids, it is likely to overheat. This is partially why it is so important for the solder to have a high thermal conductivity. It helps to counteract the fact that the gas in voids cannot conduct heat. The voids actually reflect heat back onto the component, resulting in hot spots. These hot spots can lead to issues with that component. Signals will not be sent or received, causing the product that the board is installed in to malfunction or fail. At the same time, the joint will also be weak. In some cases, the voiding percentage may not be high enough to thermally affect anything, but if the product, such as a cellphone, receives an impact; the joint may break entirely, which would also lead to the aforementioned product failure.

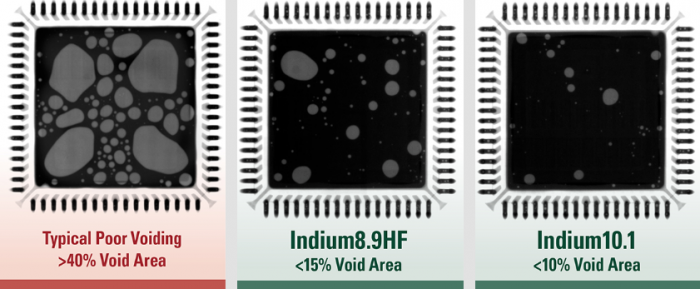

My major project for my ten weeks here at Indium Corporation is focused around decreasing voiding. By dropping the voiding percentage in the solder joints, we can increase product reliability, durability, and longevity. Wish me luck as I seek to Avoid the Void®.

Thanks for reading,

JJ