Solder Alloys

Durafuse® LT

Durafuse® LT is a patented low- to mid-temperature mixed solder alloy system developed by Indium Corporation, specifically designed for high-reliability applications that require a lower reflow temperature. Leading original equipment manufacturers (OEMs) and electronics manufacturing services (EMS) have embraced this versatile solder paste technology for various high-reliability applications, attracted by its numerous advantages and strengths.

Powered by Indium Corporation

- Low- to Mid-Temperature

- Reflows From 205°C or Higher

- High-Reliability

Product Overview

Drop Shock Reliability

Durafuse® LT offers improved drop shock resilience, outperforming bismuth-tin (BiSn) or bismuth-tin-silver (BiSnAg) alloys and demonstrating superior performance over SAC305 when optimum process setups are in place.

Thermal Cycling Reliability

Durafuse® LT provides unmatched ductility and exceptional TCT performance when reflowed at 220-245°C. Unlike conventional high-reliability solder pastes, which are rigid and susceptible to cracking, this solder paste offers distinct advantages in wafer-level CSP assembly. It effectively reduces quad-flat no-leads (QFN) cracks, thus enhancing durability and performance in challenging applications.

Sustainability

Our research has shown that by implementing Durafuse® LT, customers can achieve energy savings of up to 15%* and reduce their carbon footprint to meet global sustainability requirements.

Applications with Large Temperature Gradients

When dealing with assembly applications that experience significant temperature differentials (large ΔT) and require varying reflow temperatures while maintaining solder joint reliability, Durafuse® LT provides a broad process range of 205°C or higher. This wide window simplifies the handling of complex designs.

Durafuse® LT Products

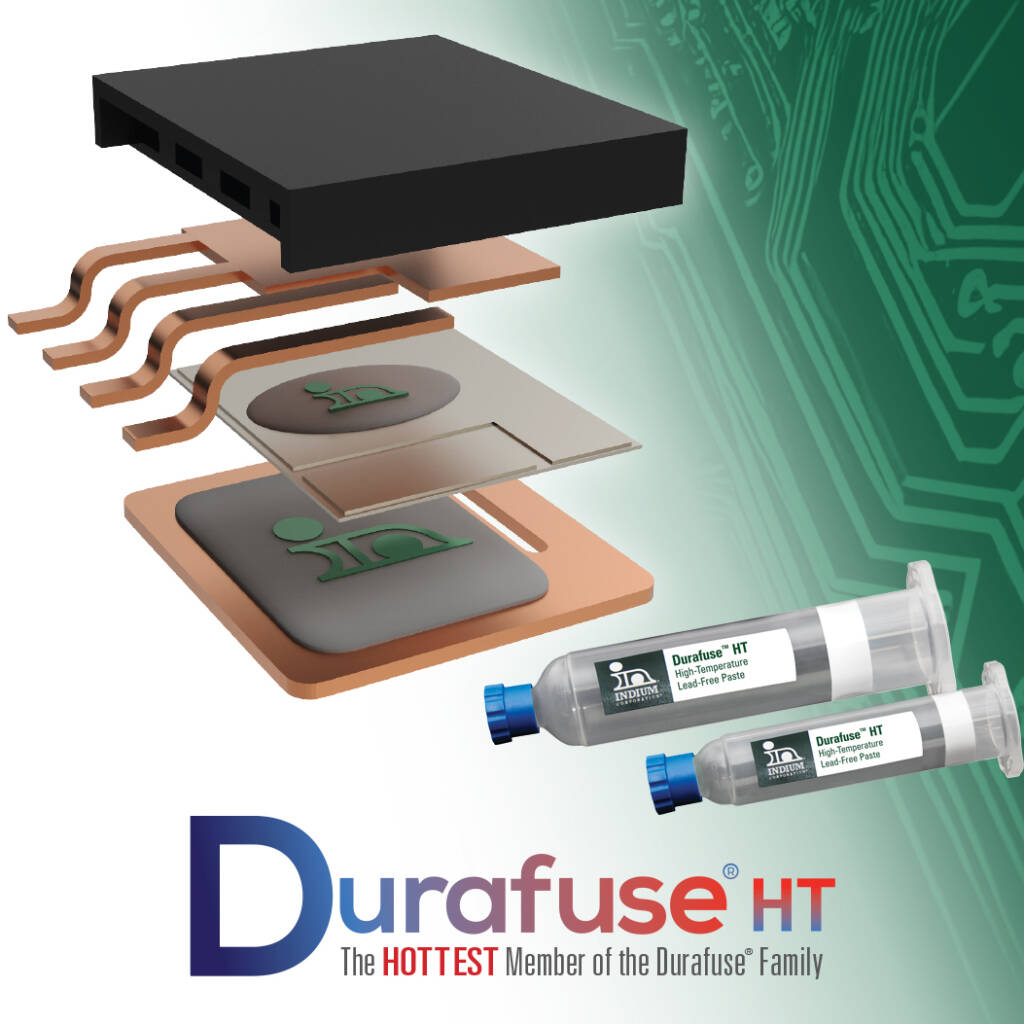

Adopted by leading OEMs and EMSs, the award-winning Durafuse® LT has been successful since its launch. This solder paste utilizes a range of both proven and novel flux formulas that demonstrate excellent performance. Additionally, we offer two other products in the Durafuse® line to cater to various requirements, including high-temperature Pb-free options and high-reliability solutions with low voiding.

Product Data Sheets

Durafuse® LT with Indium10.8HFT PDS 100118 (A4) R2.pdf

Durafuse® LT with Indium10.8HFT PDS 100118 R2.pdf

Durafuse® LT with Indium3.2HF PDS 100303 (A4) R0.pdf

Durafuse® LT with Indium10.2HFA Low-Temp Drop Shock Solution PDS 100122 R0.pdf

Related Applications

Durafuse® LT’s low-temperature capabilities are available for use in a variety of applications.

Related Markets

Durafuse® LT is used in markets that require high reliability, particularly those involving thermally sensitive components or boards. It’s ideal for step soldering and is often utilized in a variety of applications and industries.

Expert Support for Reliable Results

Do you have technical questions or sales inquiries? Our dedicated team is here to help. “From One Engineer to Another®” isn’t just our motto—it’s our commitment to delivering exceptional service. We’re ready when you are. Let’s connect!

Looking for Safety Data Sheets?

Access everything you need — from technical specifications to application guidance — in one convenient location.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.