Applications

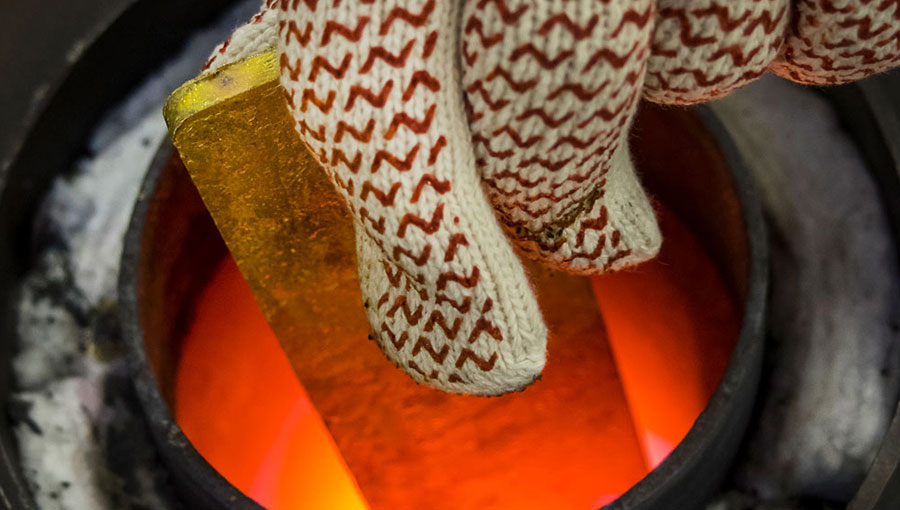

High-Temperature Soldering

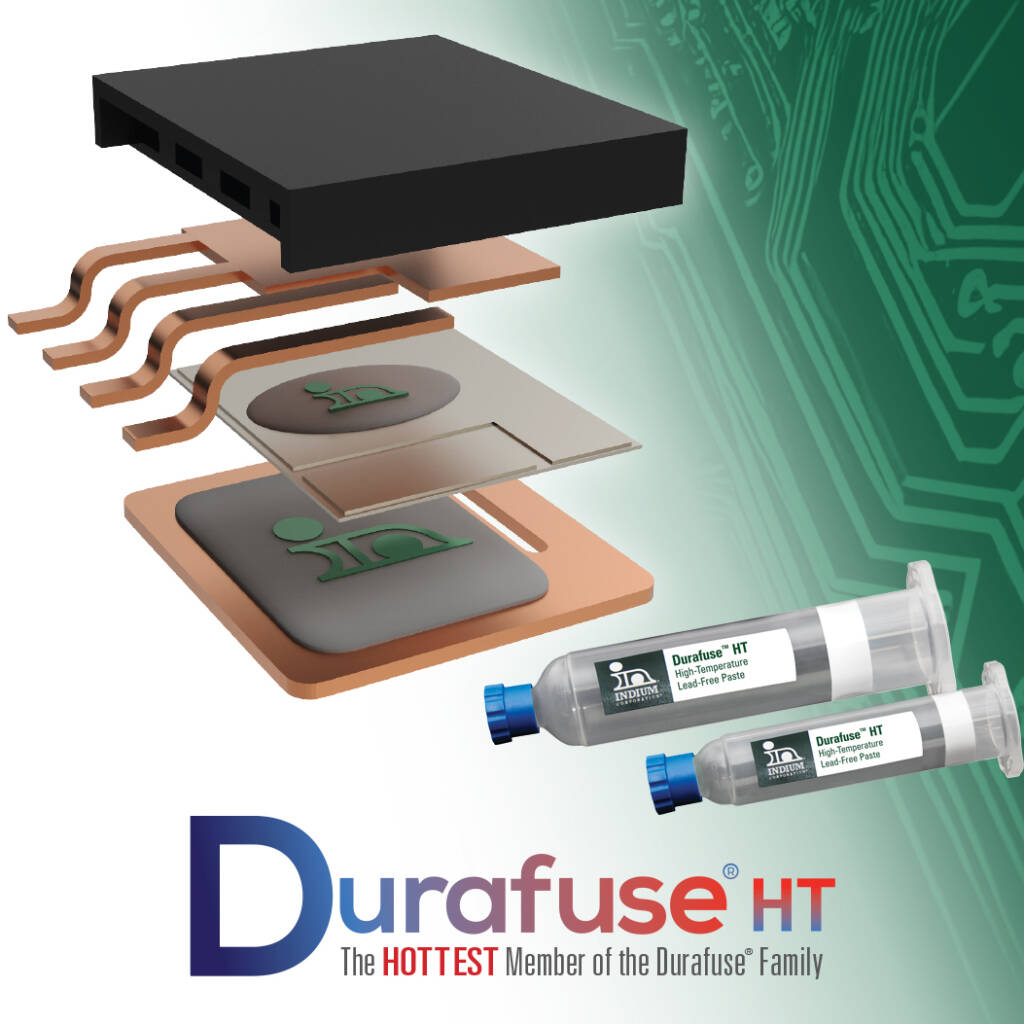

Indium Corporation is a leading gold and silver alloy bonding and brazing materials innovator for high-temperature and high-reliability applications, such as die-attach and hermetic sealing, in various industries including automotive, medical, RF infrastructure, and laser.

Overview

Indium Corporation offers high-performance soldering materials for power semiconductors and other applications in harsh environment.

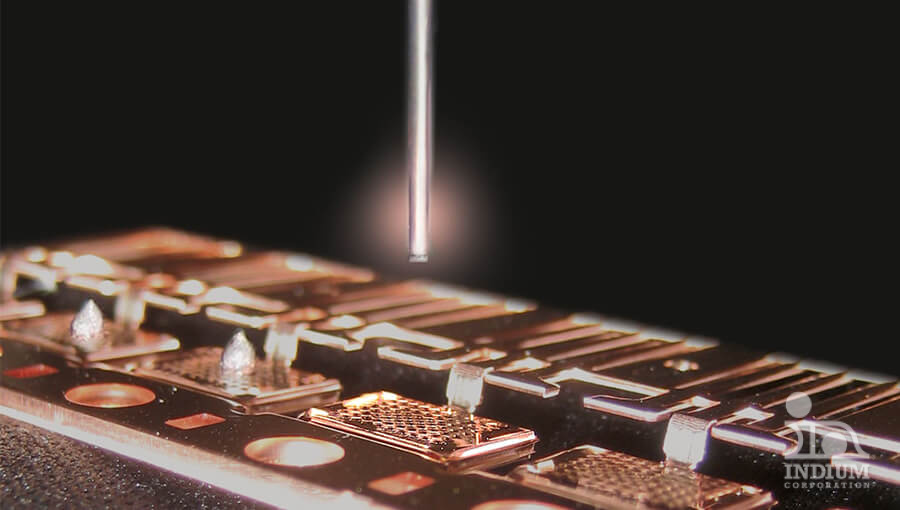

With over 200 alloys available, we have alloy solutions for temperatures up to 1,100°C. Providing an alternative to traditional high-lead options, Indium Corporation currently offers and is continuously developing novel lead-free solutions such as gold solders, sintering, preforms, and alloy technology with new flux systems.

Benefits

Gold based alloys offer strong bond strength, excellent corrosion and oxidation resistance, and good thermal and electrical transfer at the braze joint.

Strong bond strength

Strong solder joints ensure a reliable connection, which improves the longevity and functionality of the device.

Excellent corrosion and oxidation resistance

Gold solders resistance to corrosion and oxidation is important because it ensures the joint’s long-term integrity and electrical functionality.

Good thermal and electrical transfer

This creates a reliable connection that can withstand mechanical forces and provide electrical continuity.

Lead-free and RoHS compliant

Gold and Silver-based high temperature alloys provide an alternative to traditional high-lead options.

Related Applications

Related Markets

Indium Corporation is a leading gold solder innovator for high-temperature, high-reliability, and critical applications such as die-attach and hermetic sealing in:

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.