Applications

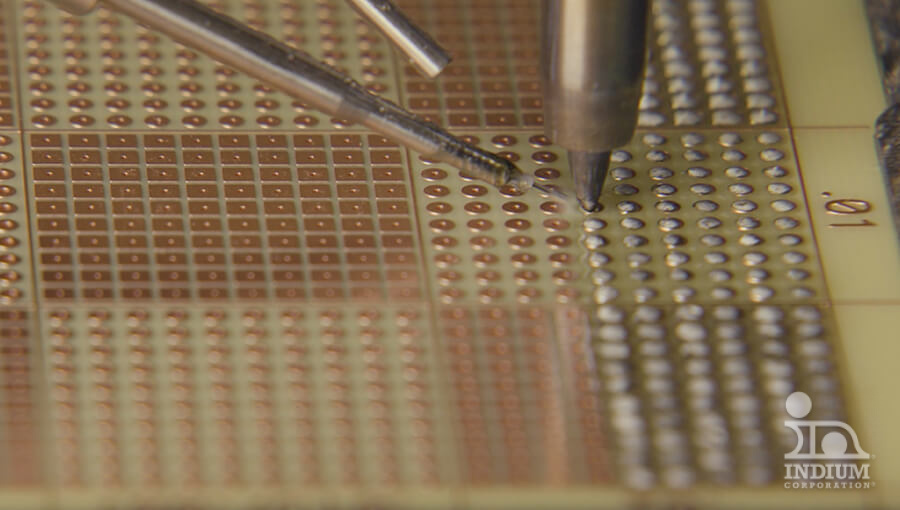

Printed Circuit Board (PCB) Assembly

Whether you’re qualifying a new product, improving process yields, or upgrading for future capabilities, our expert team and cutting-edge soldering materials can support your success in the ever-changing landscape of PCBA applications.

Overview

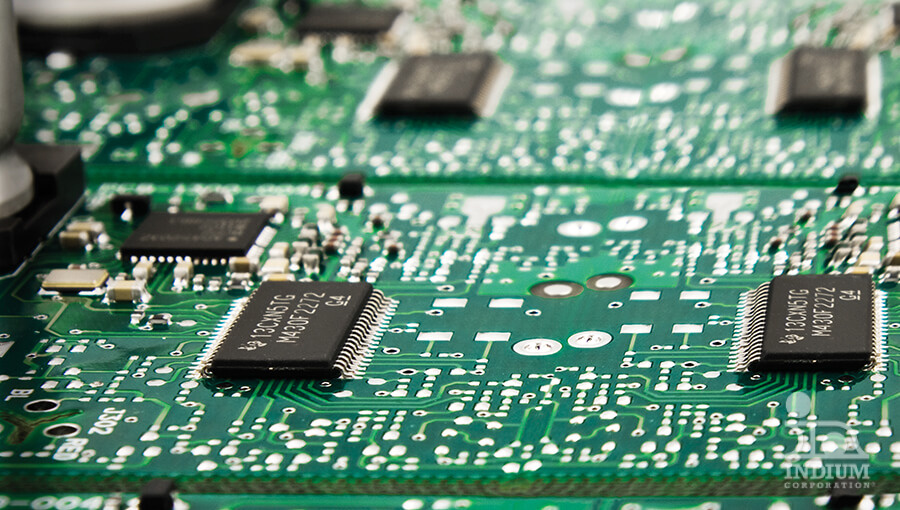

The Importance of Printed Circuit Board Assembly (PCBA) in Modern Technology

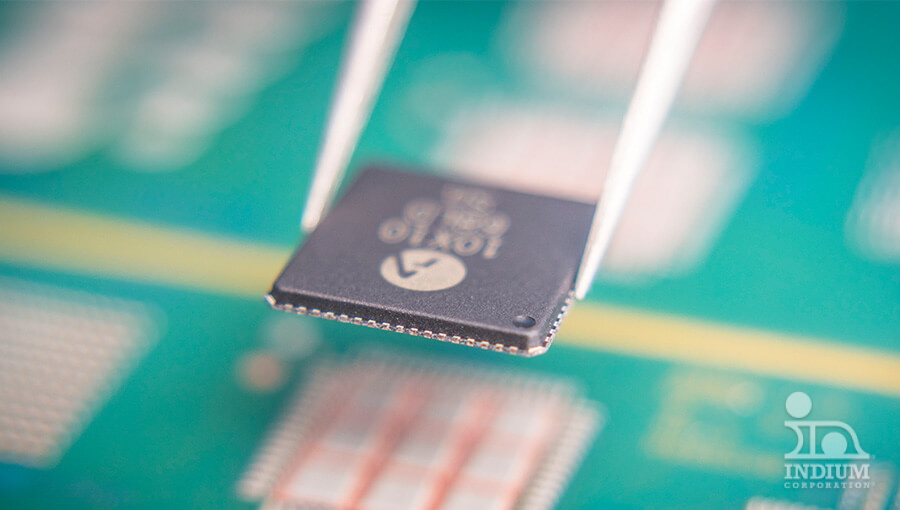

PCBA is the process of attaching electronic components to a printed circuit board. This involves key steps such as soldering, inspection, and testing to ensure electronic devices function properly. PCBA is essential for supporting modern technology in industries like consumer electronics, automotive, aerospace, and medical equipment. At Indium Corporation, we understand the complexities of PCBA and offer advanced materials and expertise to improve your assembly process, delivering high-quality, reliable electronics.

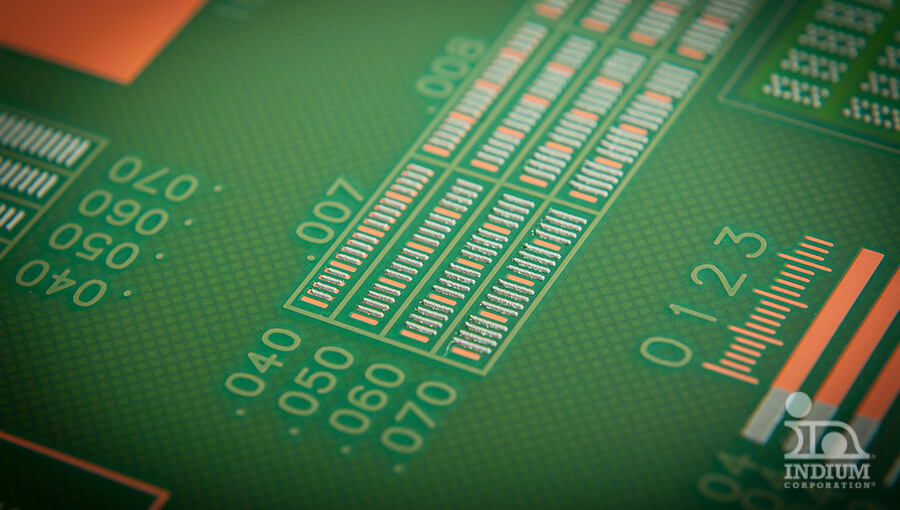

The Importance of Quality Soldering Materials

The success and reliability of any electronic device largely depends on the quality of its solder joints. Using proven soldering materials with an optimized process ensures strong, reliable connections between components and the PCB, avoiding field failures.

Benefits

What Makes Indium Corporation Different?

Extensive Expertise

With decades of experience, we understand the unique challenges of PCBA in markets such as automotive and consumer electronics.

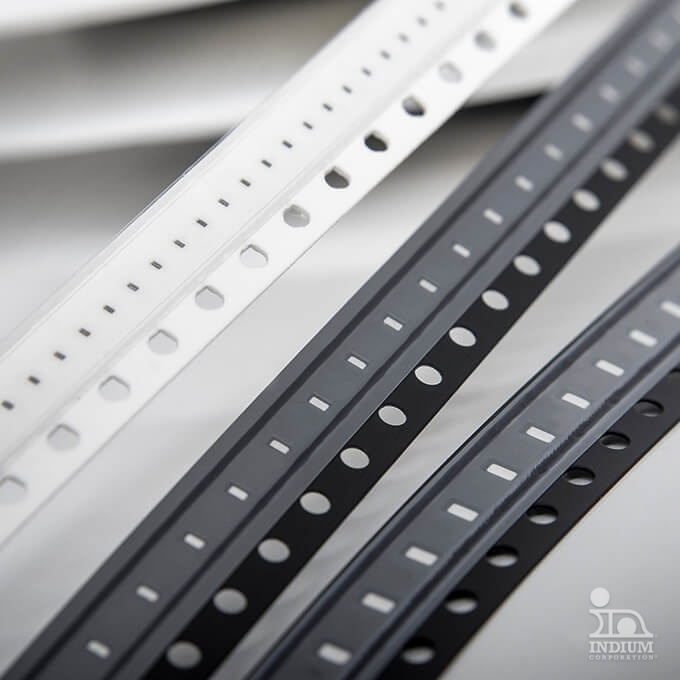

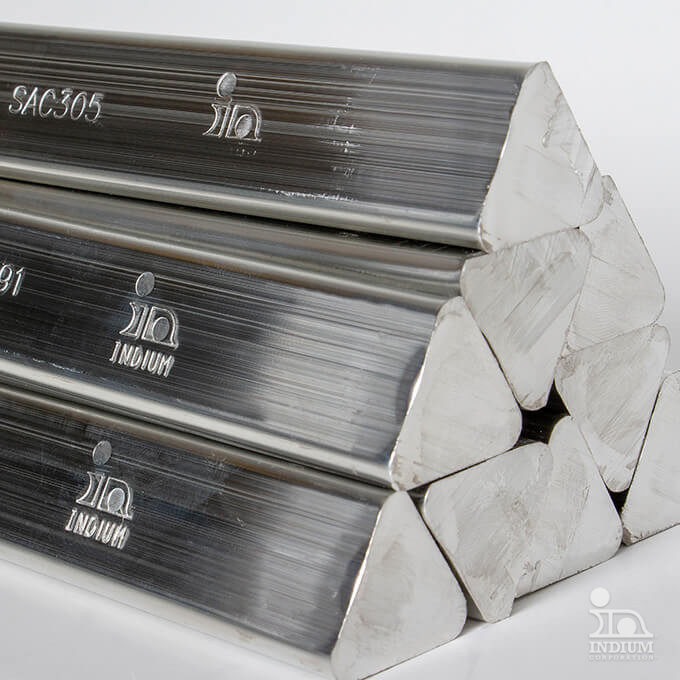

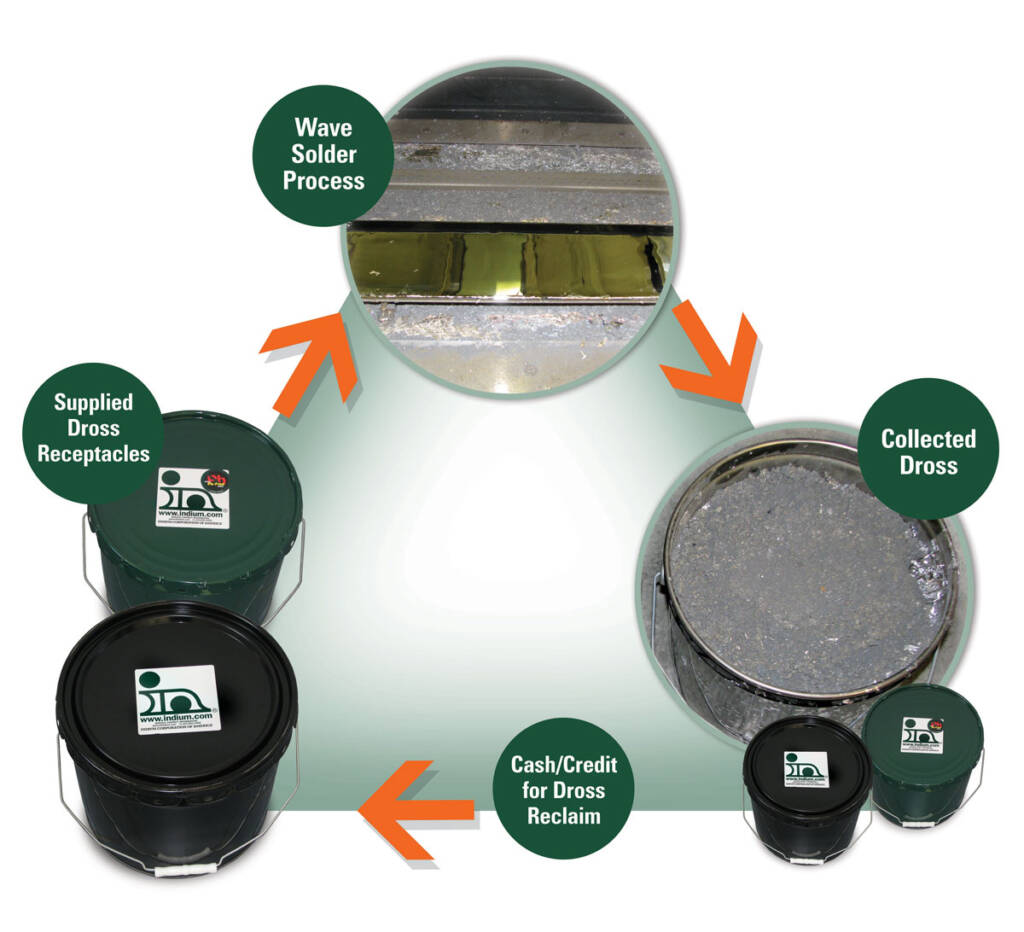

Variety of Solutions

From low-temperature solders to high-reliability alloys, we offer a wide range of materials tailored to your specific PCB assembly needs.

Cutting-Edge Technology

Our state-of-the-art products ensure efficient, high-quality assembly processes, reducing ownership costs and maximizing yield.

Comprehensive Support

Our global team of experts provides customized guidance to help you find the best solutions for your projects.

Related Applications

Related Markets

The quality of solder joints is crucial for the success and reliability of electronic devices used in everyday life, from consumer electronics to high-reliability applications in aerospace and medical fields.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.