09 Feb 2024 by Jason Farrell | View Bio

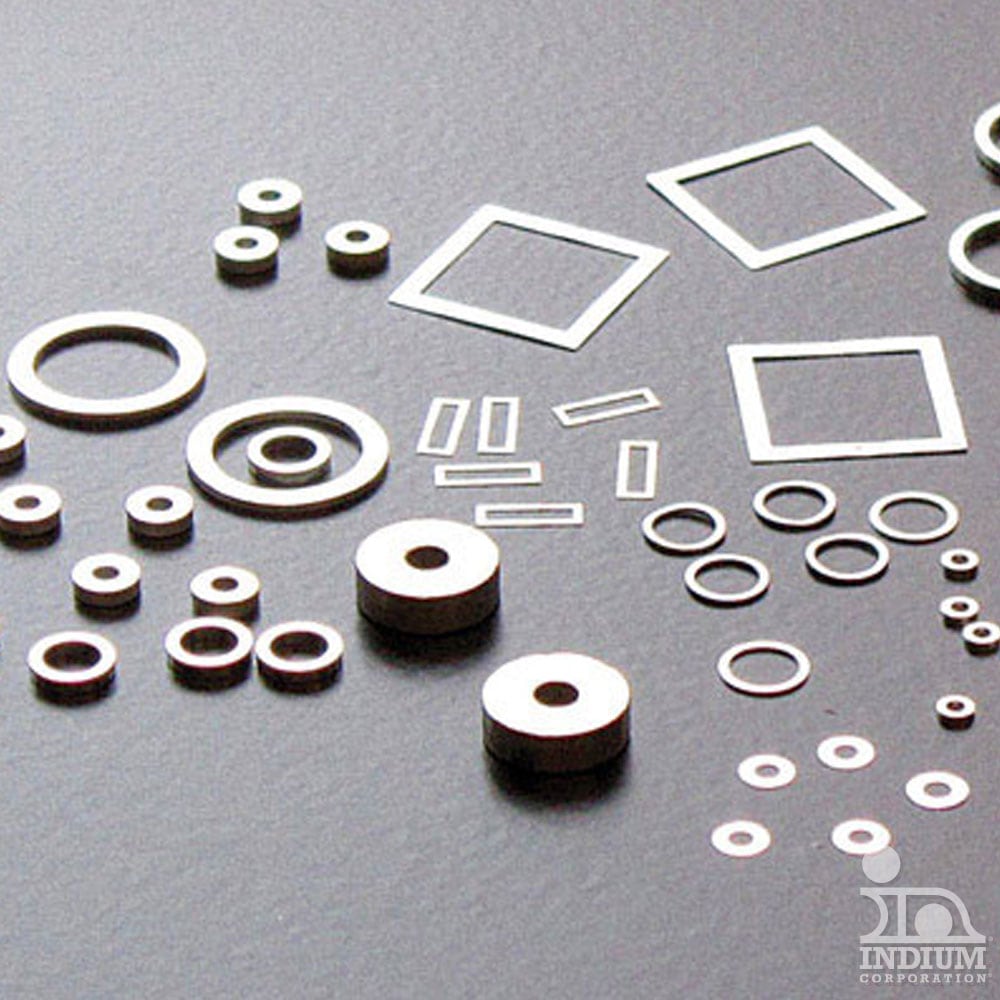

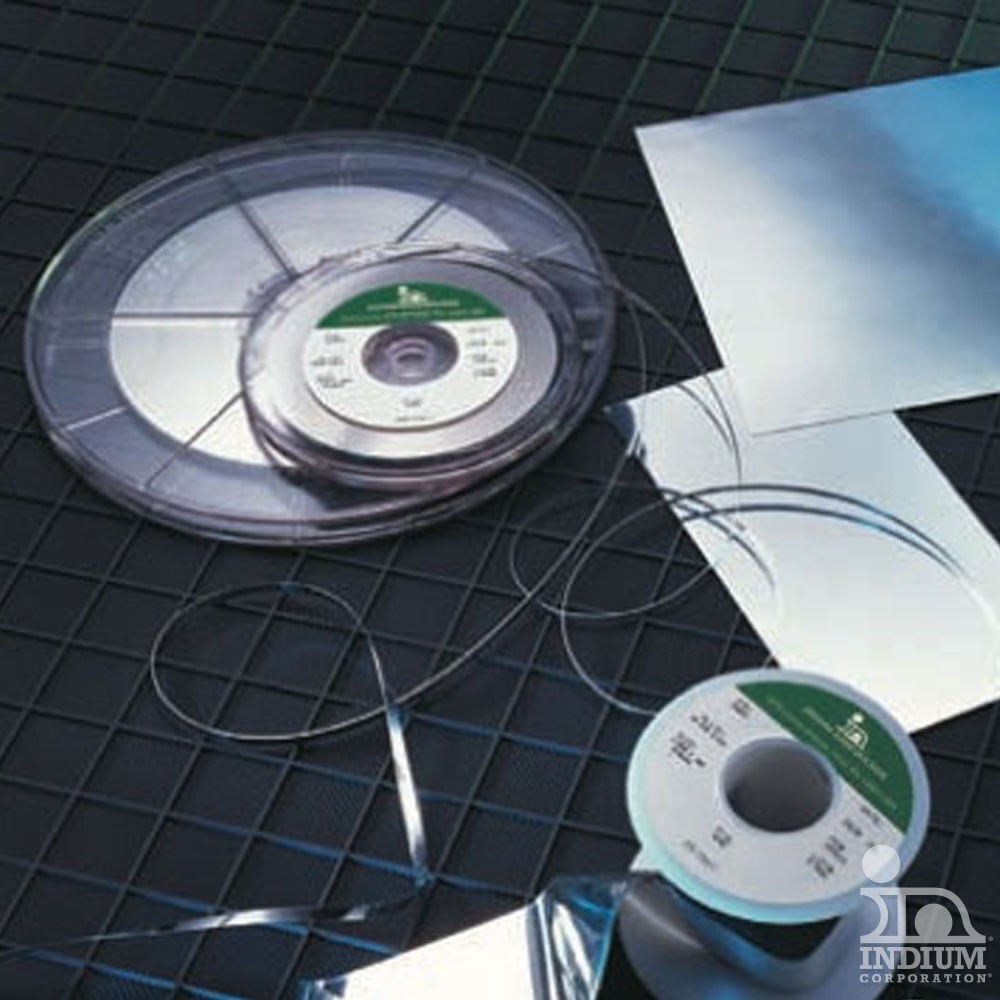

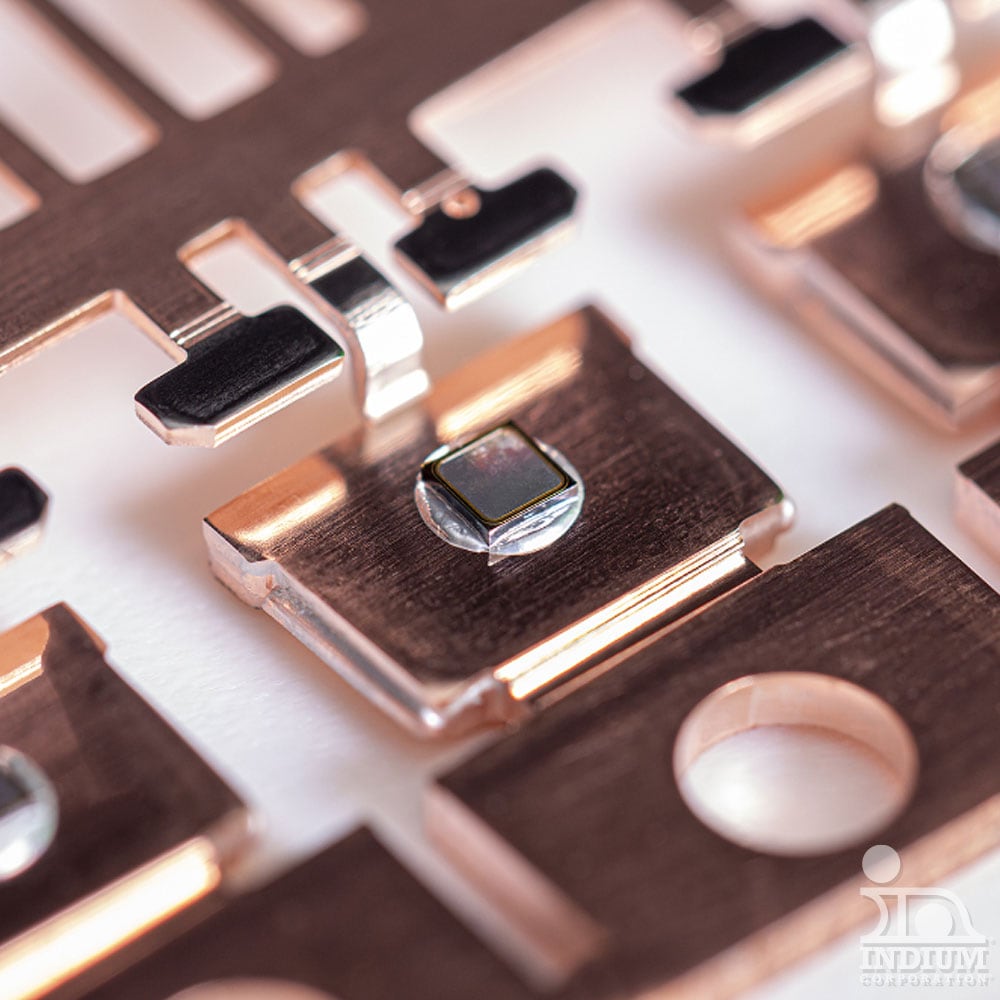

Indium Corporation® featured our Precision Au-Based Die-Attach Preforms at SPIE Photonics West 2024, the world’s premier event for lasers, biomedical optics and biophotonic technologies, quantum, and optoelectronics...

Read More16 Jan 2024 by Dean Payne | View Bio

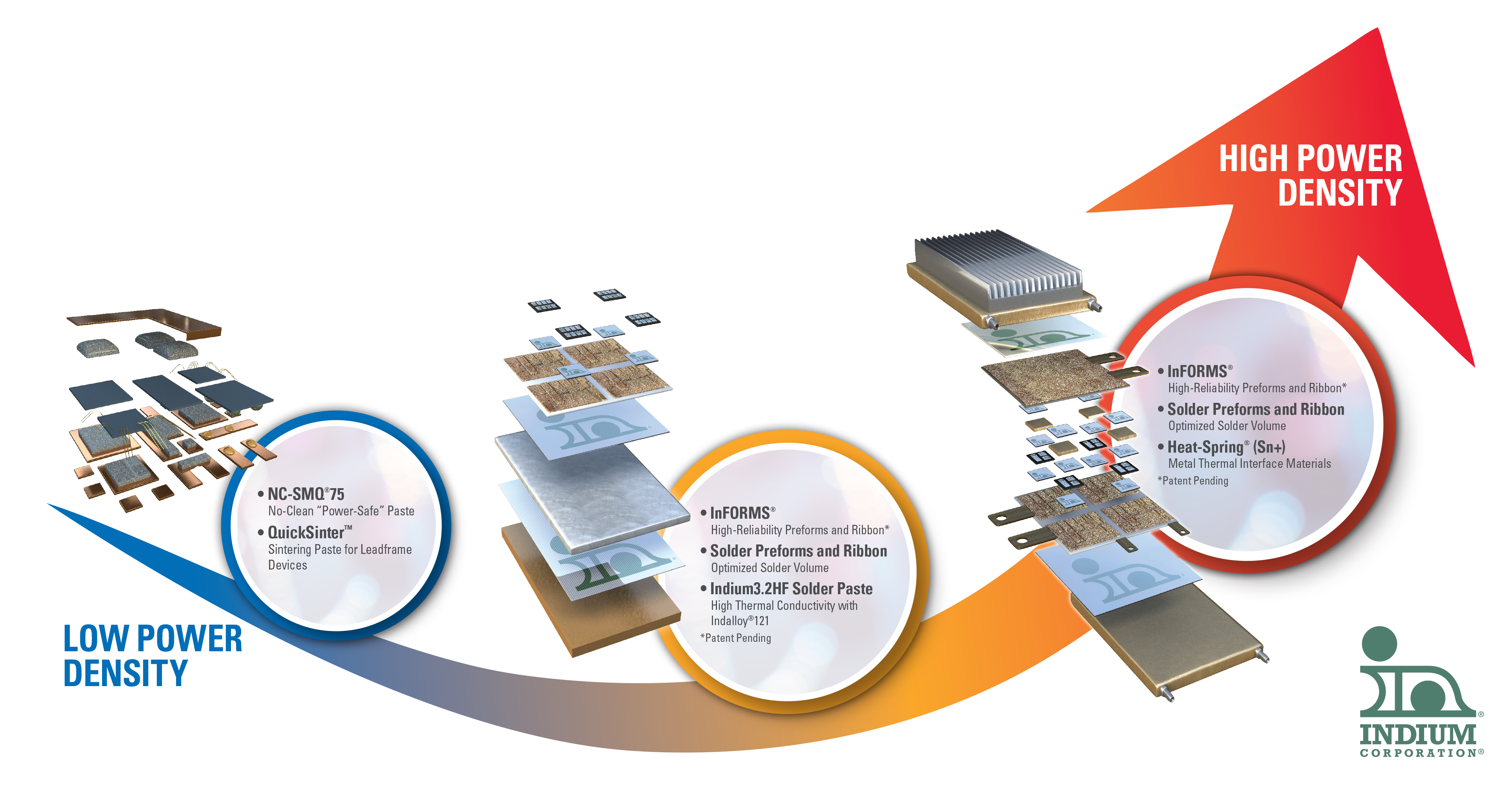

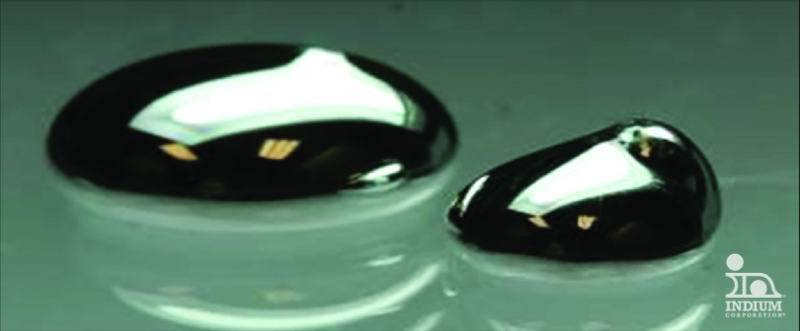

In recent years, silver sinter materials have grown in popularity in power module assembly, especially for die attach...

Read More23 Jan 2023 by Jenny Gallery | View Bio

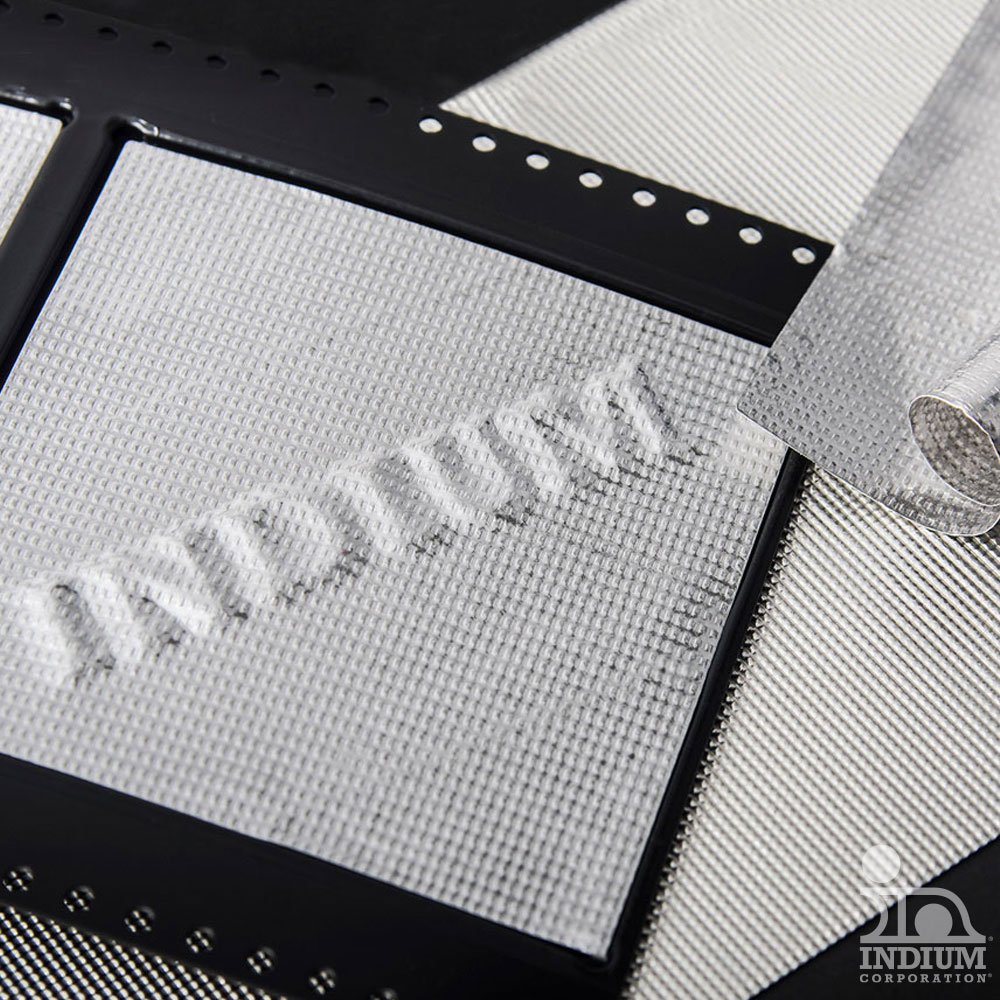

Indium Corporation to promote new specialty product offerings: AuLTRA™75, AuLTRA™ ThInFORMS™, and AuLTRA™ Fine Ribbon, at SPIE Photonics West in San Francisco, CA (January 22-27).

Read More19 Dec 2022 by Jenny Gallery | View Bio

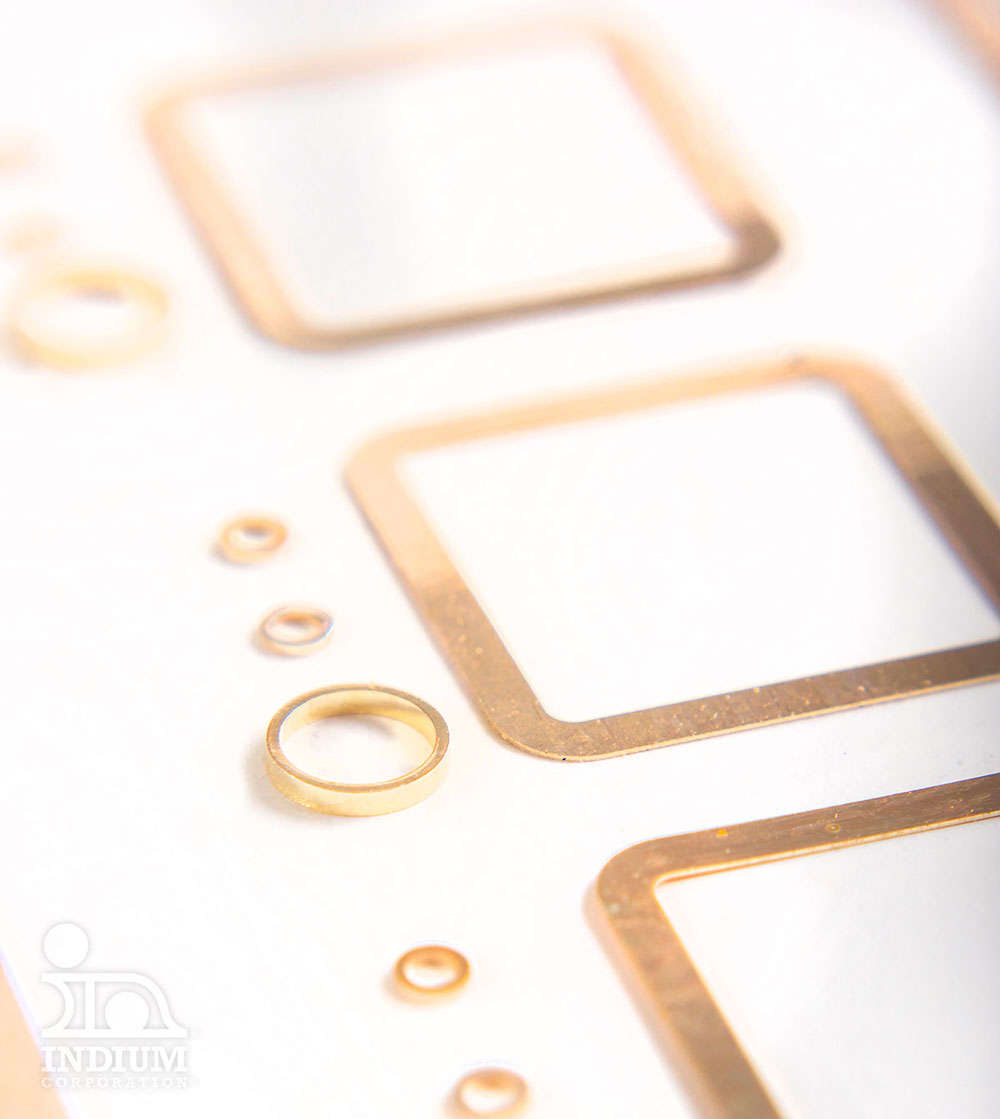

Plating dies and/or substrates with pure gold works well to prevent the components from oxidizing, but can lead to undesirable gold-rich solder joints. Using an off-eutectic AuSn alloy as the solder material accommodates for these thick gold metallizations, allowing for the exact adjustment of the final solder joint composition to guarantee strong solder joints in die-attach applications.

Read More09 Nov 2022 by Dean Payne | View Bio

Just last month at the IMAPS show in Boston, Sze Pei Lim and I had the opportunity to chat with Francoise von Trapp from 3D InCites to discuss materials ai...

Read More