Thermal Management

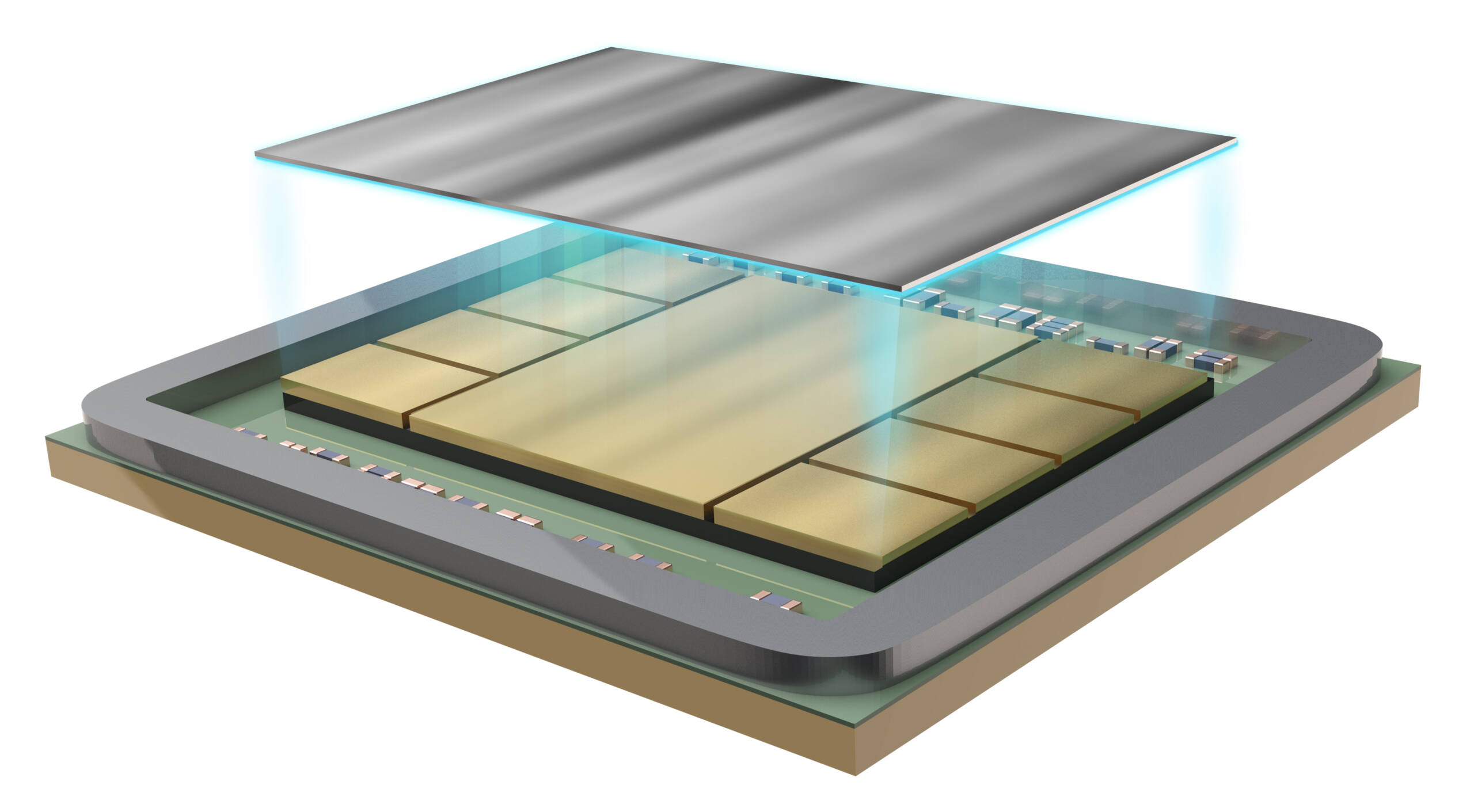

TIM1, TIM1.5, and TIM2

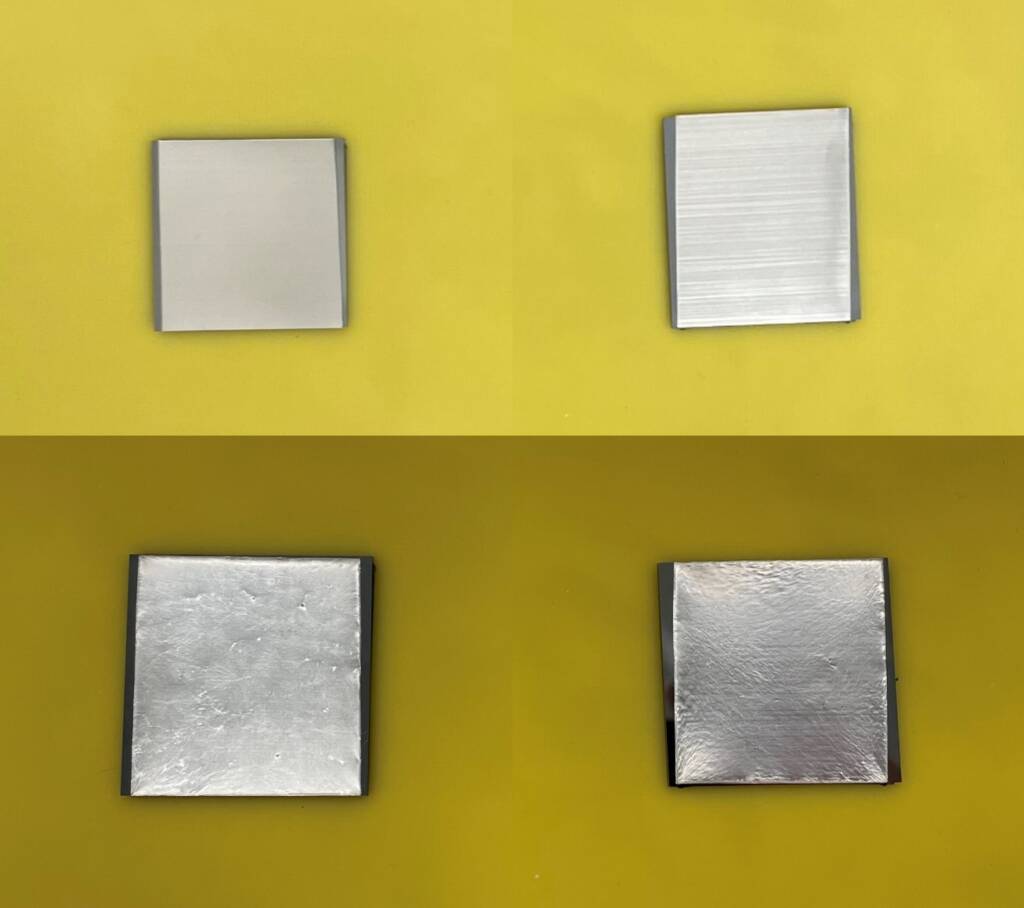

Metal-based thermal interface material (TIM) solutions provide superior thermal performance and long-term reliability across multiple layers of the thermal stack. Whether using air cooling, direct liquid cooling, or immersion cooling, these TIMs can be tailored to meet specific thermal demands. Their ability to flow and wet a wide range of surfaces, combined with high isotropic thermal conductivity and low yield and flow strengths, allows them to conform to surface irregularities, effectively reducing overall thermal resistance (Rth).

Overview

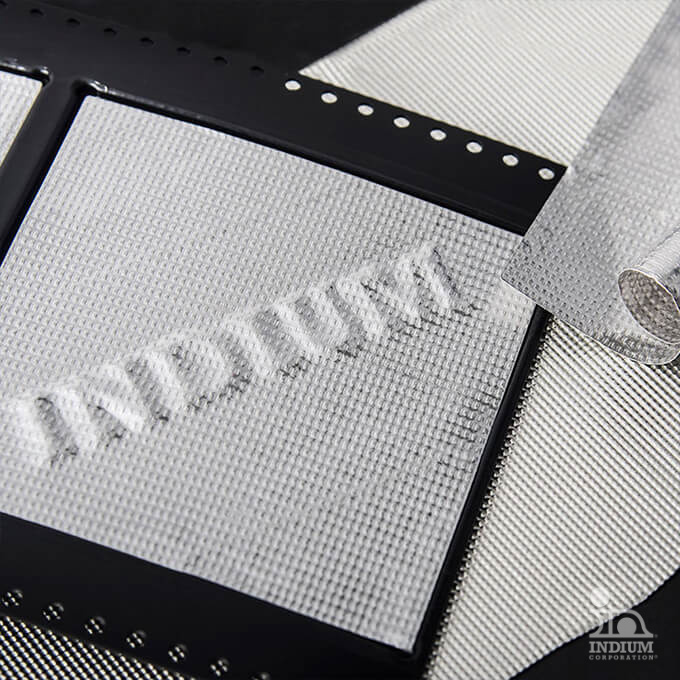

Specializing in Metal-Based TIMs with Thermal, Reliability, and Conformance Advantages

Indium Corporation leads the way in developing novel TIM and processes, including applications for TIM1, TIM1.5, and TIM2.

TIM1

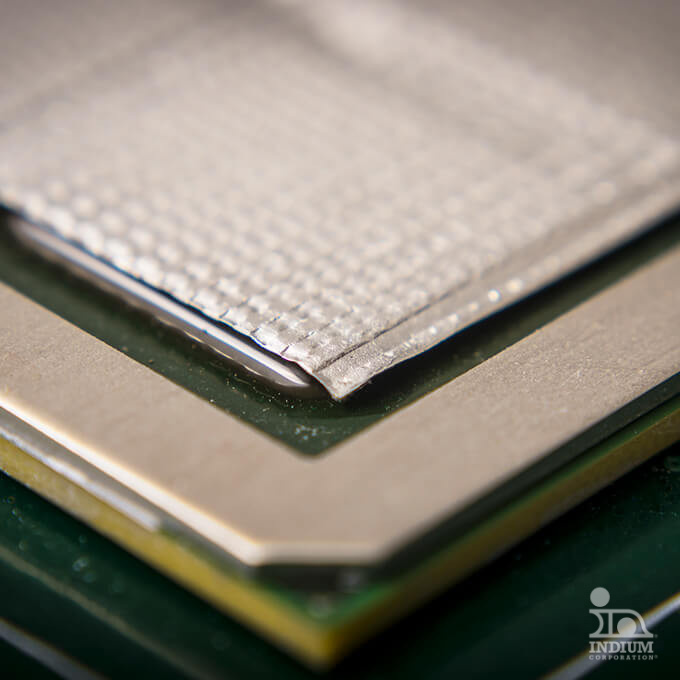

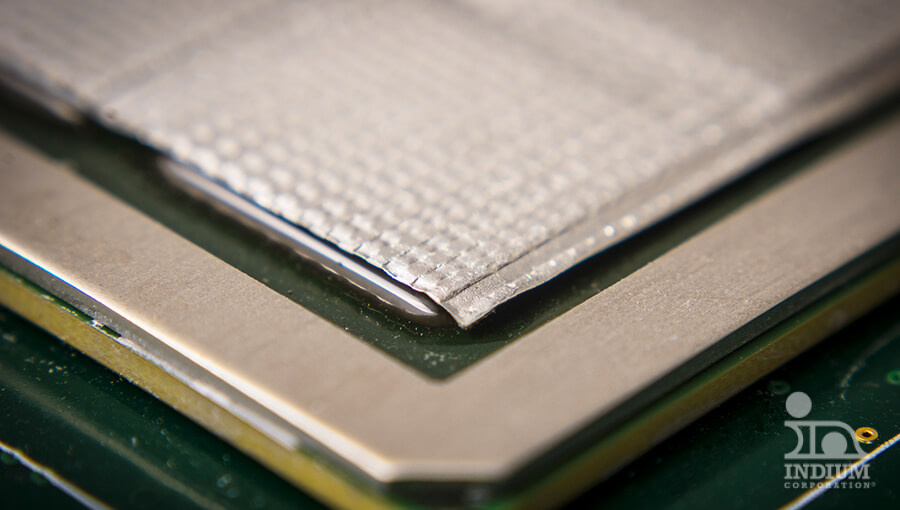

Solders and liquid metals are used as high-performance TIMs between a semiconductor die and a package lid. Reflow and non-reflow solutions are available for LGA, PGA and BGA packages that see single or multiple reflow cycles.

TIM1.5 (Bare Die)

High-performance computing (HPC) applications require best-in-class TIM materials and process expertise. TIM 1.5 (bare die lidless BGA packages) is the interface between a bare die and a heat-sink or cold plate and is often used in HPC design. Indium Corporation can help you choose between soldered, compressible, or liquid metal-based TIMs.

TIM2

TIM2 is the interface between a heat spreader or lid and a heat sink. We typically recommend compressible TIMs, such as heat-spring.

Related Applications

Related Markets

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.