Related Braze Alloys Videos

Related Braze Alloys Blog Articles

SPIE Photonics West 2024

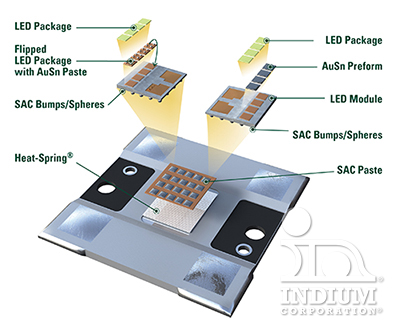

Indium Corporation® featured our Precision Au-Based Die-Attach Preforms at SPIE Photonics West 2024, the world’s premier event for lasers, biomedical optics and biophotonic technologies, quantum, and optoelectronics...

Read MoreUsing the Density Technique to Estimate Gold Mass Fractions in Gold Alloys with Silver and Copper

Folks, My second email from Adriana Re using density to determine gold mass fraction is below. She asked if we could communicate in French. The translations ar...

Read MoreCalculating the Mass Fraction of Gold in a Gold Alloy

Adriana writes, "Dear Dr. Ron. I’m trying to program the equation for determining the weight fraction of gold in scrap metal from the density of the scrap..."

Read MoreSPIE Photonics West 2023!

Indium Corporation to promote new specialty product offerings: AuLTRA™75, AuLTRA™ ThInFORMS™, and AuLTRA™ Fine Ribbon, at SPIE Photonics West in San Francisco, CA (January 22-27).

Read MoreSPIE Photonics West 2022

Indium Corporation to promote new specialty prodict offerings: AuLTRA™75, AuLTRA™ ThInFORMS™, and AuLTRA™ Fine Ribbon, at SPIE Photonics West in San Francisco, CA (January 22-27).

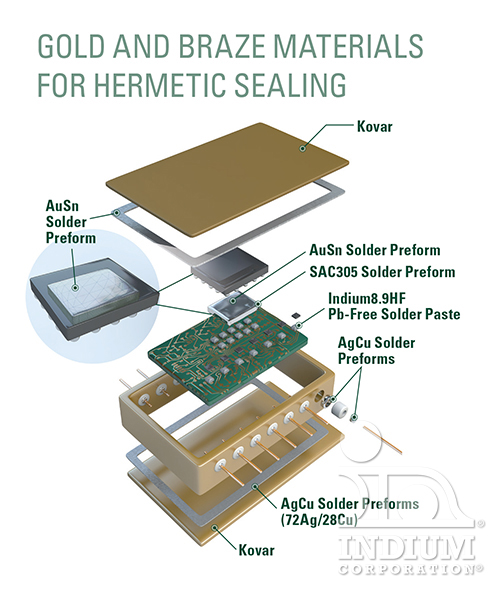

Read MoreIndium Corporation is a leading gold solder innovator for high-temperature and high-reliability applications, such as die-attach and hermetic sealing in medical, aerospace, optoelectronics, automotive, and many other industries.

Gold based alloys offer strong joints, excellent corrosion and oxidation resistance, and good thermal and electrical transfer at the joint. Our gold solder portfolio includes wire, paste, preforms, and ribbon. They are manufactured with cutting-edge technology to ensure quality as well as push the boundaries of precision.

Gold materials deliver:

- Highest tensile strength of any solder

- High melting point is compatible with subsequent reflow processes

- Pb-free and RoHS compliant

- Superior thermal conductivity

- Resistance to corrosion

- Superior thermal fatigue resistance

- Good joint strength

- Excellent wetting properties

- Resistance to oxidation

When to Choose Gold Products

Factors to consider:

- Higher yields and cost per unit make gold a viable option, even though the initial cost is higher than alternative solders

- A low oxygen atmosphere may be required if the application is flux free

- Some applications require pressure to promote good, void-free reflow on horizontal surfaces.

Processing Options

- Vacuum Soldering: flux-less and void-free soldering

- Die-Attach: high process temperature

- Reflow: convection, infrared, and induction

- Laser Soldering: targeted soldering

- Vapor Phase Reflow: uniform heating

- Manual Soldering: solder iron, hot plate, ultra sonic, and dipping

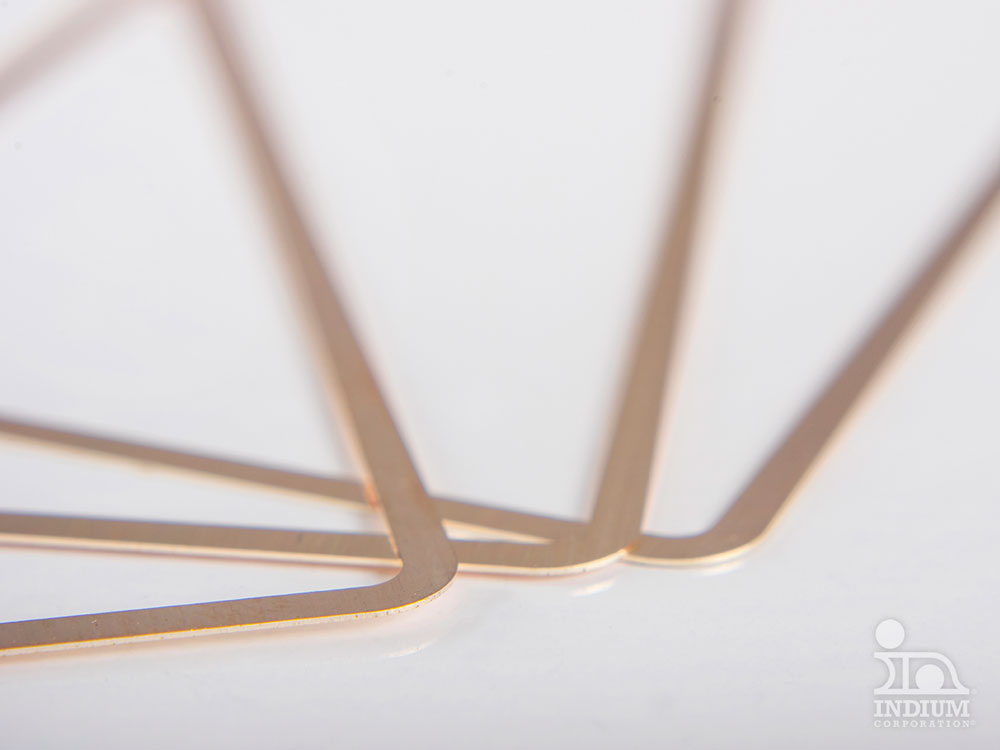

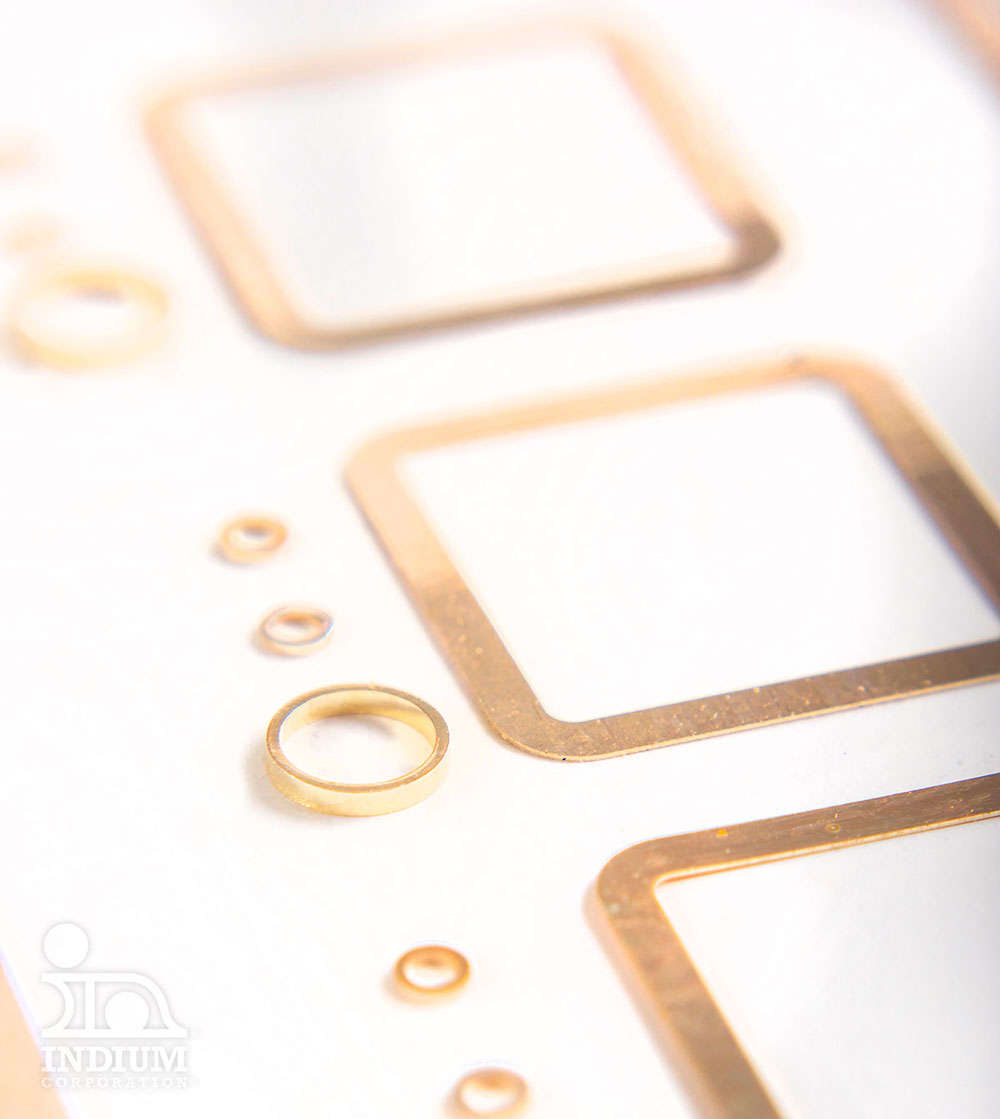

Gold Preforms and Ribbon

- Thickness from 0.0127mm (0.00035”) and greater

- Tight dimensional tolerances ensure repeatable solder volume

- Flatness measurement capabilities to 0.00254mm (0.0001”)

- Large die library with in-house tooling capabilities

- Tiny solid shapes from 0.152mm (0.006”)

- High aspect ratio and complex special shapes

Gold Wire

- Diameter starting at 0.025mm ± 0.0127mm (0.001” ± 0.0005”)

- Tight dimensional tolerances

- Packaging designed to minimize breakage of wire in soldering process

- Maximum of 80% Au

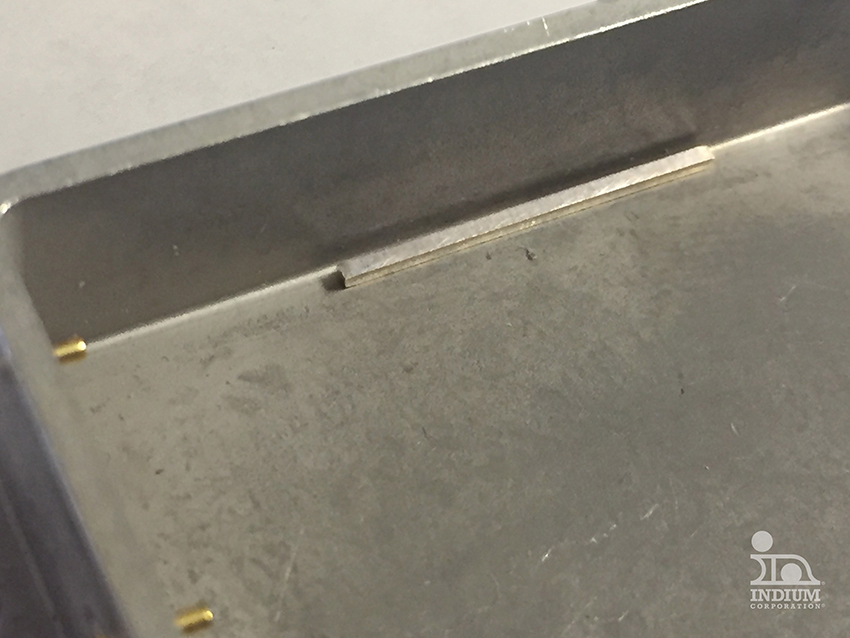

Capillary Blocks®

- New technology for brazing hermetic packages

- Cost-efficient alternative to cut wire and frames

- Doesn’t shift during movement and reflow

- Increases yields and lowers cost of ownership

Gold Paste

- No-clean and water-soluble

- Type 3-7 AuSn powder

Gold Spheres

- Sizes starting at 0.254mm (0.005”)

- Tight dimensional tolerances down to +/- 5 microns

Benefits of High-Temperature Alloys

| Attributes | Alloys | Temperature | |

|---|---|---|---|

| Gold-Based Alloys | Strong bond strength, excellent corrosion and oxidation resistance, and good thermal and electrical transfer at the braze joint. | Indalloy®200 (100Au) Indalloy®178 (82Au/18In) Indalloy®184 (96.8Au3.2Si) Indalloy®183 (88Au/12Ge) Indalloy®270 (75Au/25Sn) Indalloy®269 (78Au/22Sn) Indalloy®271 (79Au/21Sn) Indalloy®182 (80Au/20Sn) |

1064°C Eutectic Solidus 451°C / Liquidus 485°C 363°C Eutectic 356°C Eutectic Solidus 278°C / Liquidus 332°C Solidus 278°C / Liquidus 301°C Solidus 278°C / Liquidus 289°C 280°C Eutectic |

| Silver-Based Alloys | High thermal and electrical conductivity, capillaries very well into joints, and holds up well in applications with lots of stress and with CTE mismatches. | Braze Indalloy®B962 (99.99Ag) Indalloy®193 (72Ag / 28Cu) |

962°C Eutectic 780°C Eutectic |

Capillary Blocks®

Increase Yields, Quality in Hermetic Package Manufacturing with New Capillary Blocks® Technology

Indium Corporation’s new capillary blocks® technology delivers a simple, cost-efficient alternative to the current process of using cut wire or frame preforms in hermetic package manufacturing.

Used for brazing the hermetic package frame to the base, cut wire shifts during movement and reflow, resulting in quality issues. While a more stable option, frame preforms can be costly and have long lead times when tooling setups are required.

Capillary blocks® are designed with a patented square shape that keeps the material in place during movement and reflow. As a result, capillary blocks® increase yields and lower cost of ownership for hermetic package manufacturing.

Features:

- Patented design offers a stable alternative to cut wire for a higher-quality solder joint

- Reduced lead time as compared to frame preforms

- Unique shape enables a tight joint connection to aid in the capillary action

- .030” wide x .030” height (length is determined by the amount of braze needed for the joint)

- Available alloys include:

- 72Ag/28Cu

- 72Ag/28Cu VTG

- 99.9Ag

Gold Preforms

Indium Corporation provides high-performance precision gold preforms. Indium Corporation’s manufacturing Engineers have developed advancedgold and braze preform manufacturing technology to produce "best in class" precision preforms. These high-quality preforms redefine the boundaries of what’s capable in regard to complex designs and aggressive aspect ratios. Eutectic and off-eutectic options available in preforms and ribbon.