Folks,

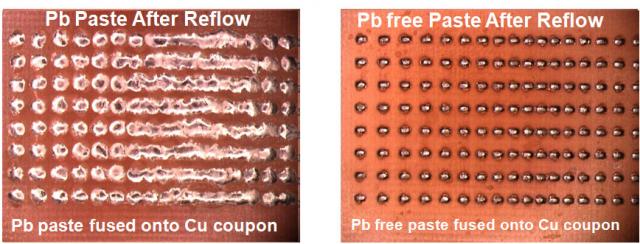

I have often pointed out that SAC solder’s poor wetting is both a curse and Godsend. It is a curse when trying to fill a through-hole in wave soldering, and a Godsend when assembling close lead spacings as shown in the image (below). Indium Corporation colleague and friend, Mike Fenner (image below), pointed out that, when I say that, “SAC solder doesn’t wet well“, I should be saying, “it doesn’t spread well“. His explanation follows:

Indium Corporation colleague and friend, Mike Fenner (image below), pointed out that, when I say that, “SAC solder doesn’t wet well“, I should be saying, “it doesn’t spread well“. His explanation follows:

SAC is different from SN63, and I think it is helpful to explain the difference by making a subtle differentiation between wetting and spreading.

SAC is different from SN63, and I think it is helpful to explain the difference by making a subtle differentiation between wetting and spreading.

The way that solders spread and wet to a surface is a balance of competing forces. We have surface tension acting to make the molten solder shrink into a ball, and wetting forces trying to make it spread across the surface. Wetting is also the action of the solder dissolving into the surface to form an intermetallic. This intermetallic is essence of the solder joint. The balance changes with different alloys, surfaces, and processes.

Most people are very familiar with the way that tin lead solders behave – and that governs their expectations. The different balance in SAC means the solder tends to spread less for the same wetting and, therefore, can give the impression of a lower quality joint. This lack of spread is usually expressed as ‘poor wetting’.

I would explain this by saying the “active ingredient” in both solder families is tin. SAC alloys have a ~50% higher concentration of tin than the Sn63 solder alloy. This gives them a higher surface tension which increases the balling (coalescing) force. At the same time, the less dilute tin, in SAC solders, dissolves into a surface faster. So the final SAC joint can have a well formed intermetallic, but not high spread. These relationships will vary with surface finish and, of course, flux chemistry and process conditions come into play, but that’s for another day. Meanwhile I hope this simplified explanation helps.

Thanks Mike!

Cheers,

Dr Ron

The solder image is courtesy of Vahid Goudarzi of Motorola.