Most SMT fluxes and solder pastes are either classified as RO or OR. Every once in a while one will see an occasional RE flux. People typically recognize ROL0 and ROL1 classified fluxes and solder pastes as being “no-clean”. And often people will “recognize” an OR classified flux or paste as being a water-washable material. But there are also “no-clean” materials that can qualify as OR. One may ask how that can be. It is actually very simple. It has to do with how RO and OR are defined in the J-STD. According to 3.3.1.1 Flux Composition in J-STD-004B “The flux shall be classified as either rosin (RO), resin (RE), organic (OR) or inorganic (IN) based upon the largest weight percent constituent of its non-volatile portion.” (Italics added by the blog author.) Virtually all low- or zero-residue “no-clean” solder pastes and fluxes have little or no rosin or resin. So, if you are a paste or flux manufacturer and you are trying to classify your rosin/resin free no-clean material with J-STD’s definitions, which designation do you choose? There is only one designation that remotely makes sense, given the four choices that you have, and that is OR.

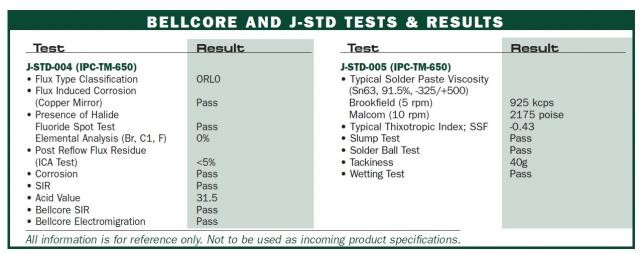

Below is an example of how the J-STD test results may look for a no-clean solder paste that has a classification as OR.

Since most OR classified no-clean solder pastes and fluxes leave little or no residue, they can be highly desirable for applications where removal of the residue is costly yet minimal flux residue is desired or necessary. Such applications involve scenarios where the solder joint will be coated with either an underfill, conformal coating, or other form of encapsulation. Traditional rosin/resin no-clean residues may not be compatible with such materials, resulting in voiding and/or poor adhesion of the encapsulate.

Low-residue solder paste and fluxes are also friendly to ICT (in-circuit testing) or other probe testing because they do not leave behind a residue that can gum up the probe or interfere with the probes contact to the pad and/or solder joint.

Don’t wrongly dismiss the usage of an OR material thinking that it requires cleaning (water washable). They are a number of OR classified materials that do not require cleaning, leave little or no residue, and are therefore quite useful in a number of applications that involve subsequent encapsulation.