It seems like a fairly simple thing to do. What could be difficult about soldering a wire to a pad?

Well, I hear three common complaints and expressions of frustration:

POSITIONING: Typically, in this process, a soldering iron is used. The first problem arises from trying to hold onto the soldering iron AND the wire to be joined to the prefluxed pad AND the solid-core solder wire you are using. An extra hand would be nice! Some people use a system of fixtures or clips to hold the wire and the pad in the appropriate position. (see image and link, below)*.

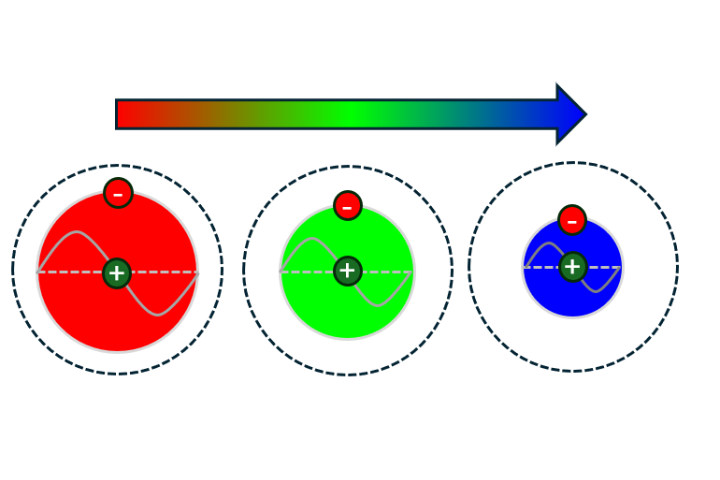

COLD SOLDER JOINT: Another common complaint is that, after soldering, the wire easily pulls out of the solder joint. This is due to the poor wetting of the solder to the wire and the pad – it never really "soldered". A solution that I share is to pretin both the pad and the wire with the solder, using a flux. To pretin the wire, I suggest melting some of the solder in a crucible or solder pot. Dip the wire in the flux and then into the molten solder. A teardrop should form on the end of the wire. It can also be pretinned using the soldering iron. Next, pretin the pad. Both pretinned surfaces will have a coating of post-reflow flux residue. If required, this residue can easily be removed using a suitable solvent. Now that you have pretinned both surfaces, the pad should be heated with the soldering iron and, when the proper temperature is reached, the pretinned wire should be pressed to the pretinned pad. The solder on both the pad and the wire will melt together and, when the heat is removed, the joint will be formed. Usually this can be accomplished without adding additional flux.

INCONSISTENT VOLUME: A third issue is that the volume of solder in the joint is not uniform from piece to piece. If this is your concern, consider using a flux-coated solder preform. They can be produced with the exact solder volume, and the precise dimensions to fit onto the wire you are joining to the pad. Similar to the process described above, when the pad and the wire are heated, the flux will be activated (removing the oxides) and the solder preform will melt, forming a consistent and perfect solder joint.

Please contact our technical support group with any questions you may have. We are always ready to help you solve your soldering problem, whether it is large or small.

For more background, read these blog posts on hand soldering:

- soldering iron tip temperature

- hand soldering flux selection

- hand soldering tech support

- the importance of a clean soldering iron tip

*Image: Harbor Freight sells a product called "Helping Hands" for (US) $6.99, as of this writing. Other companies offer similar products. Consider buying more clamps to hold the wire in place, freeing you to hold only the solder wire and the soldering iron.