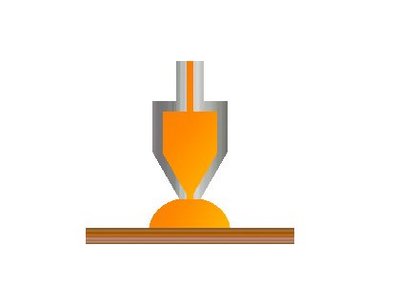

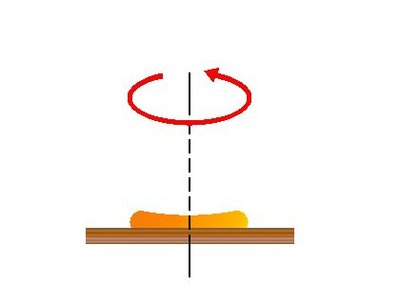

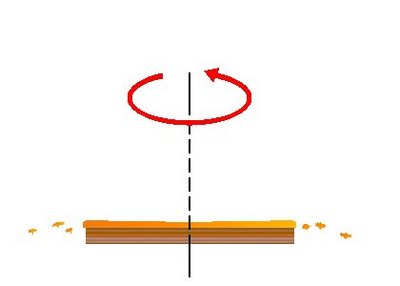

Spin coating is an amazingly simple way to apply flux to a (generally round) substrate. Most commonly used in wafer processing, spin coating can be used as a more uniform alternative to spraying liquid fluxes onto wafers for electroplated bump formation. Here is an image tutorial to introduce the process:

Spin Coating for Beginners

Indium Corporation Blogging Team

Our blogging team includes engineers, researchers, product specialists, and industry leaders. We share expertise in solder materials, electronics assembly, thermal management, and advanced manufacturing. Our blog offers insights, technical knowledge, and solutions to inspire professionals, showcasing product innovations, trends, and best practices to help readers excel in a competitive industry.