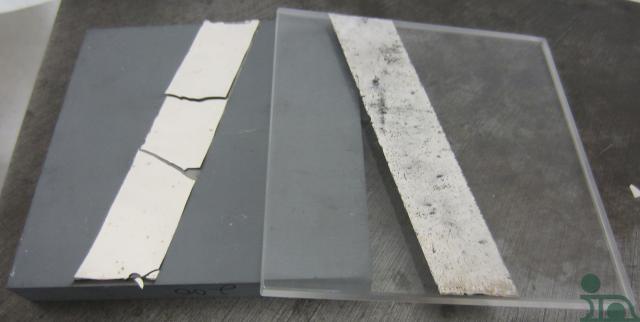

InCuSil™ is a common term for an alloy of indium, copper, and silver which (depending on composition) has various melting points in the brazing range. We at the Indium Corporation use InCuSil™ as an outer coating on standard NanoFoil®, to help the Ni/Al bond with the surrounding solder layers. (Seen here: a thin layer of InCuSil™ [right] partially stripped from reacted NanoFoil® [left].)

InCuSil™ is a common term for an alloy of indium, copper, and silver which (depending on composition) has various melting points in the brazing range. We at the Indium Corporation use InCuSil™ as an outer coating on standard NanoFoil®, to help the Ni/Al bond with the surrounding solder layers. (Seen here: a thin layer of InCuSil™ [right] partially stripped from reacted NanoFoil® [left].)

When alloyed at 61.5%Ag, 24%Cu, and 14.5%In, the resulting metal has a solidus point of 630°C and a liquidus of 705°C. It is applied to the NanoFoil® as a final PVD (Physical Vapor Deposition) coating step, to a thickness of 1 micron (μ) per side.

Since the only function of the InCuSil™ alloy on NanoFoil® is to promote bonding, there are some applications where it is not needed – and therefore not applied. These applications are generally for fuses and other pyrotechnic devices.

If you’d like to learn more about NanoFoil®, send us a question!