SigFolks,

Let’s check in on Patty as she is about to wrestle with claims of a 10 Sigma Solder Paste Printing Process involving the world’s smallest electronics components, known as 01005s.

Patty was sitting in her office contemplating beginner’s luck. She was adding this topic to her statistics class that she was preparing to teach next term. At first, she thought that beginner’s luck was a fallacy. But, she had recently read several accounts that convinced her that randomness can explain it. These and other types of statistical phenomena are discussed in N. N. Taleb’s landmark series of books, Fooled by Randomness, The Black Swan, and Antifragile.

The beginner’s luck argument goes something like this: say a group of about 20 people go to Las Vegas to gamble for 5 days. Five of the group have never gambled before, so they are considered to be beginners. On average, the members of the group will lose money, but some percentage of them may end up winners. Let’s say that the percentage is about equal to about one third. So at the end of five days, about 7 of our total entourage will end up winning, and, on average, about 2 of those will be beginners. People look for reasons to assign to statistically random events, so the group will ascribe the winning of the two beginners to beginner’s luck. No one thinks about the 3 beginners who lost.

The next year, the same group goes again. Last year’s beginners have not played since last year, so they would still be considered beginners. One of the two winning beginners from last year, let’s call her Mary, wins again. This event would not be statistically unusual, but Mary is the talk of the group; “She won twice because of beginner’s luck,” they will say. In addition, no one notices that, of the three beginners that lost last year, one of them won this year.

The third year Mary loses, as the odds have caught up to her. Everyone concludes that, since she is now no longer a beginner, beginner’s luck has left her. Yet, all of this story can be explained by simple statistical randomness and the human need to find a cause for a given result.

As Patty was finishing her Powerpoint® slides on this topic, she was disturbed by a knock at her door. It was Janice Austin, from Ivy University’s Development Office.

“Professor Coleman, I just want to thank you for saving the year for us,” Janice began.

Patty looked at her dumbfounded. The Development Office was the organization that sought contributions from alumni, wealthy patrons, and industry. Patty’s confusion showed.

“How did I save the year?” Patty asked.

“ACME Corporation just contributed $100,000 and the citation accompanying the check stated that it was in recognition of the outstanding work you have done for ACME, the electronics industry, and the community. Without this check we would have missed our target this year. I’m quite sure President Hotchkiss will be over to offer his thanks, too.” Janice said.

After a few more pleasantries Janice left. Patty stared off into space. Then it hit her, Mike Madigan wanted a “blank check” to have her, Pete, and the Professor work on projects for him. How could they say no to the company that donated $100K? She had to chuckle at the cleverness. Madigan would avoid having to pay any consulting fee, which could add up. As she returned to her work, Pete showed up at the door.

“Hey, Professor! Pack your bags. A trip is in play,” Pete cheerfully began.

“Looks like some statistical process control issues in ACME’s Charlotte facility,” Pete finished.

Patty didn’t know whether to be angry or amused that even now that they were at Ivy University Pete still always seemed to know what was going on before she did. Patty and Pete chatted for awhile and then he left.

Patty was really happy for Pete. Working in the engineering department at Ivy U had really turned out well for him. He had been a machinist earlier in his career and these skills, along with his 25 years of experience in industry, had prepared him to be a godsend to the engineering students at the university. Ivy U Engineering prided itself in being a place where students learned not just the “knowing” of engineering (ie the classwork) but the “doing” of engineering (making prototypes and models in the machine shop). So, Pete was in demand as a resource to the several hundred Ivy U engineering students to help them with this “doing” aspect of engineering. It was clear that Pete had never been so happy.

As she was thinking these pleasant thoughts, Patty was startled by the ringing of her phone. It was Mike Madigan.

“Professor Coleman, it’s Mike Madigan. Could you and Pete go to Charlotte and straighten out an issue with Cpk?” Madigan implored, getting right to the point. He continued, “They are claiming Cpks of over 3 and yet yields are off slightly. As you will remember Cpks for printing are usually around 1. I’m having a bit of a challenge with the site manager, Byron Hansen, in staff meetings as he is claiming that the other sites should be able to improve their printing performance to match his team. I give it right back to him about the slightly lower yields. The entire issue is causing me problems with the senior staff as Hansen has been teasing them about their lower Cpks. Can you help us straighten it out?” .

Since it was between terms at Ivy U, Patty and Pete were able to travel to Charlotte within a few days. They both hoped they might squeeze in a little golf as there was snow in central New Hampshire. However, Patty pointed out that, even though it was warmer in North Carolina, it still got dark abound 5PM, making golf after work impossible.

Patty and Pete arrived at their destination at 3PM for a brief kickoff meeting. The meeting began with introductions. Patty was shocked to see one of her former statistics students (from spring semester), Frank Stockton, approach her.

“Professor, it is good to see you,” Frank sang out cheerfully.

“Likewise, Frank,” said Patty with much less enthusiasm.

Frank had been a lackluster student. Patty specifically remembered that he skipped class on one of the days that she was teaching statistical process control. It was easy for her to remember this because she gave a brief attendance quiz that day. After finding out that he missed the quiz, Frank wanted to take it. However, the entire purpose of an attendance quiz is to encourage attendance. Frank was a multi-sport athlete and was close to probation, grade wise. He was worried that he might not be able to play his sport during the next term if his statistics grade was too low. He ended up going to the Dean to try and get Patty to let him take the quiz. The Dean supported her position that Frank was not entitled to take the quiz. Frank’s concerns were realized when he was kicked off the baseball team for too low a GPA.

As the meeting began, Patty was surprised that Frank was presenting. The sole topic was Cpk for stencil printing of 01005 passives.

“We measure the volume of the solder paste at ten 01005 passive pad locations on each board, for ten boards each hour,” Frank began.

“How do you select the locations?” Patty asked.

“We have looked at historical data and the sites appear to have similar print volumes,” Frank answered.

Frank then showed some of the data and his argument that the site section was reasonable was convincing.

However, Patty thought the sample plan a little strange. She would have expected something like 10 samplings on one board or one sampling on 10 boards. But she couldn’t really find a fault in the plan.

“Your Cpks for the data you have collected are amazing, but yields are down somewhat. This situation seems counterintuitive. What do you think is going on?” Patty queried.

The site general manager, Byron Hansen, chimed in, “We have been getting sub-standard PWBs from our supplier. We have an amazing team here for stencil printing. I’m surprised that other ACME sites can’t equal our Cpk of greater than 3. You know that is more than a 10 sigma process, much less than a 1-in-a-trillion defect rate.”

Patty felt something wasn’t quite right, but she couldn’t put her finger on it. Many other issues were discussed and the end of the day was at hand. They would meet again the next day.

While Patty was in the meeting, Pete was out on the shop floor seeing what he could learn. They agreed they would meet for dinner to discuss what they had observed.

A few hours later, Patty and Pete were dining at a restaurant called Fatz. Patty didn’t think the name was very inviting, but the food was great.

After they were seated, Pete didn’t waste any time, “They’re cheating,“ he said, getting right to the point.

“What makes you think that?” Patty asked.

“I talked to Pam Scaglia,” Pete began.

“I remember her, she was a technician who took Ivy U’s Lean Sigma Green Belt course. She was a great student,” Patty interrupted.

“One and the same. She told me that they are averaging the ten readings on each board and treating that as raw data. She pointed it out to Frank, but he told her she didn’t know what she was talking about, because she was only a technician and he was a graduate of Ivy U.” Pete continued.

Hearing this further annoyed Patty. It really bothered her when someone like Frank would treat a technician like that.

Before they knew it, the next day had arrived. Patty and Pete were meeting with the Charlotte team, continuing the discussion on the Cpk of stencil printing solder paste deposits for 01005 passives. Frank was showing a Minitab graph of the data. Patty thought she would listen without comment until Frank finished.

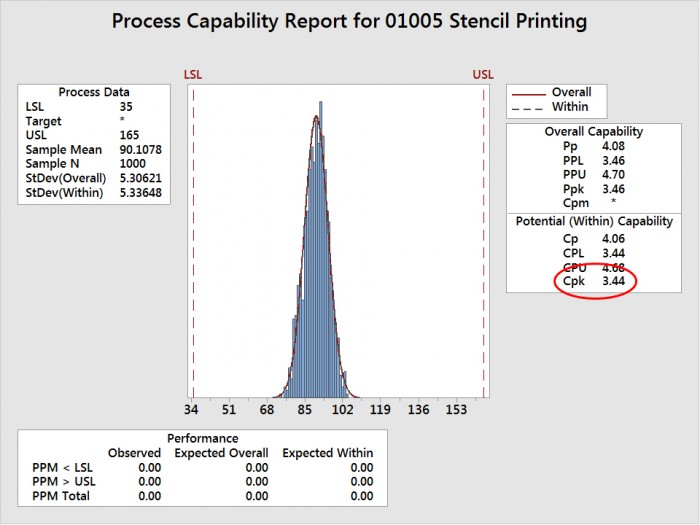

“As one can see from Figure 1, the Cpk is 3.44,” Frank concluded with confidence.

Figure 1.

“As I understand it, the data are for 10 boards at 10 sites each and this procedure was repeated 100 times?” Patty asked.

“Correct,” Frank answered.

“I’m confused,” Patty said.

“Ten times ten times 100 equals 10,000. The data in Figure 1 only has 1,000 points,” Patty went on.

“We average the ten samplings on each board and use the average as a single data point,” Frank replied.

“Would you send the raw data to me in an email, right now?” Patty asked.

Patty could tell that Frank did not want to give her the data, but he could hardly refuse since the reason Patty was there was to verify that the site was analyzing Cpk data correctly.

“Why does this matter?” Byron Hansen asked agitatedly.

“The standard deviation of the raw data is critical in calculating the Cpk. If you average some of the data first, the resulting standard deviation will be reduced significantly, giving a higher Cpk than actual,” Patty answered.

Frank and Byron looked troubled and annoyed.

While there was silence, Patty reiterated, “You must use the raw data to calculate Cpk.”

Patty went on, “From Figure 1, the upper spec is 165% of the aperture volume and the lower spec is 35%. Corporate guidelines are 150 and 50 percent respectively.

“These 01005 passive components are truly “01005” (0.01 x 0.05 inches) in dimension, not the original 01005s of a few years ago that were actually 016008. We are one of the first sites that are using them and I made the decision to relax the spec a little.” Hansen said tauntingly.

Hansen was correct, when 01005s were announced, a few years ago, they were a step smaller than 0201s, but, actually, larger than 01005 in size.

“You did this without any engineering studies, or corporate approval?” Patty asked incredulously.

In Patty’s old job, she would have to approve any spec changes like this.

While all of this was going on, Patty used Mintab to analyze the data correctly.

“By using the upper and lower specs of 150 and 50 percent and not averaging the 10 readings on each board, here is the correct Cpk calculation,” Patty said.

Patty had connected her laptop to the projector and everyone looked at Figure 2.

Figure 2.

“Note that the actual Cpk is 0.81, about 20% less than the corporate target of 1.00. Or a 2.43 sigma process,” Patty concluded.

At this, Hansen stood up and shouted, “Coleman, go back to your Ivory Tower at Ivy U and leave us alone so we can get our work done!”

Hansen then stormed out of the room.

Patty couldn’t help herself, “Frank, you shouldn’t have skipped the class on statistical process control. We covered Cpk that day,” she said.

At that, a red-faced Frank joined Hansen in departing the room.

Epilogue:

Mike Madigan insisted that the Charlotte site calculate Cpks with the corporate mandated spec limits and use only raw data. He no longer had problems with Byron Hansen teasing the other site GMs about his better Cpk values, since they were actually worse.

Frank Stockton ended up taking Ivy U’s Lean Six Sigma program and now knows how to calculate Cpks correctly. While taking this course he stopped by Patty’s office and apologized for skipping class.

Pete heard from Pam Scaglia that Frank was treating her with more respect and was even asking for advice in some SMT process issues.

Patty expected that this wasn’t the end of little adventures like this, as it appeared that ACME no longer had someone filling her former role.

Note: As with most Patty and The Professor stories, this one is based on true events.

Cheers,

Dr. Ron