Folks,

Patty really liked living in Woodstock, Vermont. She enjoyed the wildlife that literally came up to her kitchen window. A family of deer came by on a regular basis and recently a red fox came around, but she was a little unsettled when her twin sons and husband Rob came into the house and excitedly told her there was a black bear in one of the trees on their lot. Patty urged caution, but Rob quickly went back outside with a camera to get a photo. The boys followed him.

“Be careful,” Patty shouted.

“Don’t worry hon, only one person has ever been killed by a black bear in the US,” Rob replied.

Rob ended up getting a photo of a contented looking bear.

While they were taking the photo, Patty went on the internet. Her three “men” came in, in a few minutes after Rob took a few more photos.

“Where did you learn that only one person was killed by a black bear in the US, the number is more than 40since 1900!” Patty lectured Rob.

“Opps,” Rob sheepishly replied.

It was a little hard to settle down that evening, but Patty finally fell asleep with the alarm clock waiting to wake her at 5AM.

With an uneventful morning and the kids safely on the school bus, she was in her office by 8AM. Her voicemail showed a message from her former boss, Mike Madigan of ACME Electronics. She returned his call.

“Professor Coleman, thanks for calling back,” Mike answered her call.

“What’s up Mike?” Patty responded.

“Well some of our engineers did a cost study and they think we should switch vendors and buy our solder paste from AJAX,” Mike said.

Patty groaned.

“Mike you know we spent a lot of time evaluating pastes when I worked for you. The one we selected was the best, AJAX was the worst. In addition, the solder paste company that won the trials has a reputation for excellence and honesty. The AJAX people were the opposite and they lied to us on several occasions,” Patty said her voice shaking a little.

“I know, I know,” said Mike, “but we now have 200 lines and spend about $20M a year on paste. If we buy from AJAX, the cost goes down to $18.5M.”

“But the increased rework and quality issues will more than eat up the $1.5M,” Patty shot back.

“Our engineers calculated that rework would only go up about 20%, since the standard deviation of the transfer efficiency is only 20% higher with the AJAX paste. Currently we spend about $2M a year on rework, almost all due to excess solder paste being printed on 01005 passives. The first pass yield fall out for this defect is 2%. So they claim the rework costs will go up proportionally for $2M to $2.4M,” Mike elaborated.

Patty was beside herself.

“Mike you know that there might well be unintended consequences in choosing a second rate paste, beyond just rework costs,” Patty argued.

“I agree, but help me, my engineering team took this initiative, which is good. I need some argument to not follow their recommendation, that’s why I called you,” Mike said almost pleading.

By now, Patty had calmed down.

“OK, I’m going to need some metrics and a little time, but I should be able to have something by this afternoon,” Patty said.

Mike gave her the metrics she asked for and Patty went to work calculating.

Later that day, Patty called Mike back.

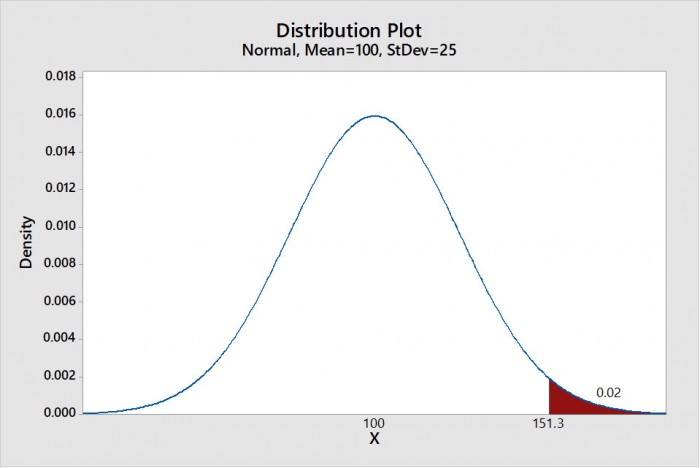

“My analysis is undoubtedly simplistic, but it gets at the heart of the matter. Assume the transfer efficiency (TE) of the current paste is such that on the high side 2% of the prints have too much paste. See figure 1 that I sent you. This number matches the 2% first pass yield fall out. Note in figure 1 that the TE at this point is 151.3%. The current paste’s standard deviation on 01005 passives used in this analysis is 25%. These passives are where you are getting the most fails,” Patty began.

Figure 1. Transfer efficiency data with the current solder paste. Note only 2% of prints are above 151.3%.

“Makes sense,” Mike replied

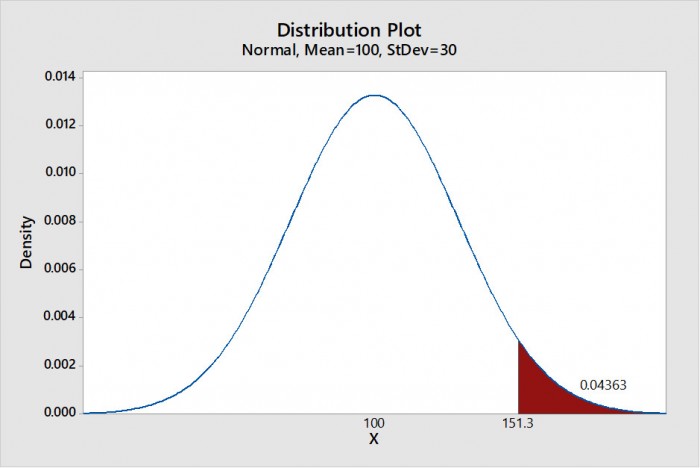

“Now look at figure 2,” Patty commanded.

Mike immediately saw it.

“The number of defects will more than double,” he exclaimed.

Figure 2. Transfer efficiency data with the AJAXsolder paste. Note only 4.363% of prints are above 151.3%.

“Why is that?” he asked.

“As you can see, the normal distribution curve is not linear, a 20% increase in the standard deviation (from 25 to 30%) increases the number of prints beyond a TE of 151.3% by over 230% to 4.363%,” Patty replied.

“So expect defects to more than double, costing more than $4M to repair and resulting in a net loss over using the current solder paste,” Patty went on.

Mike asked Patty to host a Webex to explain the analysis to Mike’s engineers.

After discussing the details, Mike summed up the situation, “I guess like everything else, quality more than pays for itself with solder paste.”

Patty quietly said an “Amen” to that!

Cheers,

Dr. Ron

Note: The bear photo was taken in the author's back yard by Zack Pearsons in May 2019. Used with permission.