Recently I caught up with Ed Briggs, a member of Indium Corporation's technical staff. I asked Ed if he would share with us his thoughts on "graping" and how to minimize it. His comments follow:

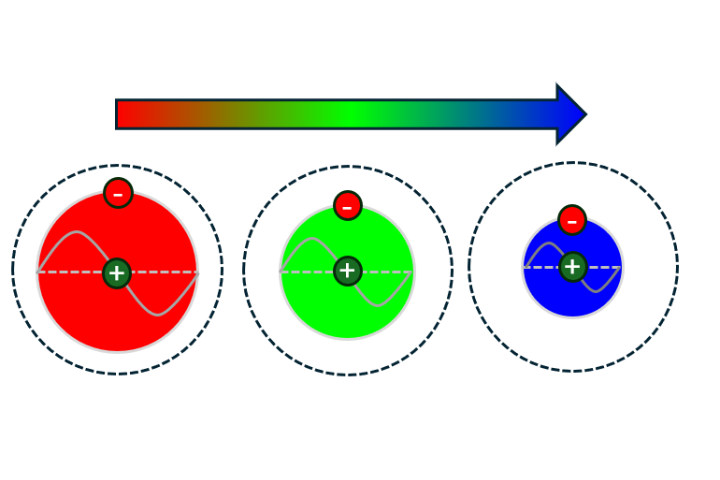

Graping is a phenomenon which appears as un-reflowed solder particles atop the solder mass (see figure above). Graping occurrence has increased due to the higher lead-free reflow temperatures, the decrease in volume of the printed paste deposit, and finer powder particle sized solder pastes required in miniaturized electronics.The combination of these factors, puts a lot of "pressure" on the solder paste flux to remove the surface oxides. In addition, during the reflow process, the flux can "run-away" from the solder powder particles, spreading and pooling about the deposit. The exposed powder particles become oxidized. With no flux to protect or remove the oxide, these particles do not coalesce into the solder joint.

With smaller print deposits, the surface area exposed to the reflow oven environment increases in relation to the total amount of solder paste deposited. Thisratio of flux to powder decreasing means there is less flux available to remove oxide from the joining surfaces and the solder powder particles within the solder paste itself. This situation can lead to graping.

Graping is much less prevalent in solder mask defined pads, perhaps due to the "damming" affect provided by the solder mask, fixing the amount of flux spreading that can occur. Also, resistors are more prone than capacitors to graping. The low stand-off of the resistor can promote the "wicking" away of the flux from the solder particles.

A reflow profile with a slow ramp rate (<1C/s) can aggravate the graping phenomena. The solder paste alloy's "viscosity" is unchanged until it reflows when it reaches the melt temperature, however the flux viscosity is easily affected, by each degree in temperature. A slow ramp rate allows plenty of time for the solder flux to "run away" from the solder powder particles, forming a larger pool and spreading out at the base of the solder deposit exposing the top/outer particles to the oven environment, easily oxidizing them. Increasing the ramp rate (1-1.5C/s), allows the flux solvent to volatize quickly, increasing the flux viscosity, lowering its ability to "run-away, " hence minimizing graping.

Modern solder pastes have also been developed to help minimize graping. If graping is a problem with your process, your solder paste supplier's technical team may be able to offer additional advice tohelp minimize this relatively new defect.

Thanks Ed!

Cheers,

Dr. Ron