Folks,

Most articles discussing the copper-tin intermetallics that form during soldering refer to them as a necessary evil. The evil being the perception that intermetallics are brittle and can lead to failures in thermal cycling or drop shock.

I view the situation differently. From my perspective, the formation of copper-tin intermetallics is the miracle of soldering. Look at it this way, to assemble electronics, bonding copper to copper (the leads on the components to the pads on the PWB) in the presence of polymers (the PWB epoxies and the component cases) is required. These polymer materials can only take about 250°C for a few minutes. Copper melts at 1083°C, so bonding copper to copper in the presence of polymers would appear to be quite a challenge. Enter tin-based solder.

Lead-free (tin-based) solder, say SAC305, melts at about 219°C. So, with a peak temperature of about 245°C, in the reflow oven, solder can be melted and form an electrical and mechanical bond with the copper in the leads and pads. At 245°C, the many polymer materials are unharmed for the 90 seconds or so that soldering requiresat this temperature.

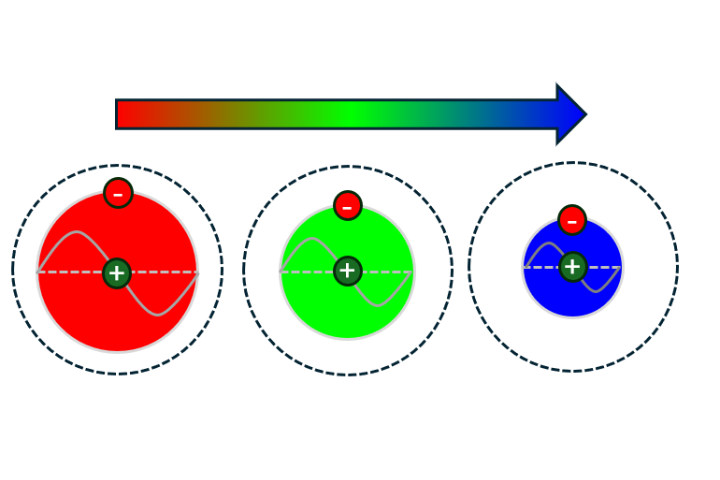

But, what about the material properties of the intermetallics that are formed? Aren’t they too brittle? Lee et al* performed analyses that suggest that the intermetallics formed in soldering are not brittle. Their work also suggests that the failure modes are not in the intermetallics, but in the interfaces between the intermetallics and the solder, copper, or the different intermetallic compounds, Cu3Sn and Cu6Sn5. These two intermetallic compoundsare shown in the figure below.

Figure. Copper tin intermetallics from Roubaud et al, "Impact of IM Growth on the Mech. Strength of Pb-Free Assemblies," APEX 2001.

It has long been assumed that the thicker the intermetallics, the greater the risk of failure due to the intermetallic thickness. Lee’s work would appear to bring this concern into question.

Stay tuned for a continued discussion on intermetallics and their effect on reliability.

Update: There continue to be numerous articles about:

- Robots putting so many people out of work that it will create a crisis

- Self-driving cars are only a few years away

AUTOMATION: As I write this post in late April of 2017, we are well beyond 100 years or automation if we choose to use Ford’s 1913 assembly line as a starting point. Atthe birth of the assembly line the world population was 1.8 billion and life expectancy in the USA was around 50 years. Todaythe worldhas 7.5 billion people and the US life expectancy is close to 80 years. I don’t want to minimize the challenges that continued automation creates, but we live in one of the few times where obesity, not starvation is a risk, even in many developing countries. This bounty and health has been brought to us by automation and science. Sure, there will be disruptions, but I don’t see this positive trend abating.

SELF-DRIVING CARS: The issue is in the definition. For self-driving autos and trucks to be truly disruptive they must never need human help. If they need some help, a human has to be there at the controls. So, if a truck needs human help 1% of the time, a truck driver will still be needed. I look forward to the many advances along the path to self-driving cars, but still think the day of the auto with no steering wheel or gas pedal is still decades away.

Cheers,

Dr. Ron