Folks,

I recently developed some Excel®-based software to help those who are planning to take the SMTA certification exam to practice. Software to design stencils already exists on the Indium Corporation Website.

In this post, I will discuss the tool that performs line balancing. In a typical SMT assembly line, the placement machines are the “gate” in the cycle time of the line. To assure that their cycle time is the lowest, the placement machines must be time balanced. For example, suppose a simple SMT assembly line has one chip shooter and one flexible placer. Let’s say that the chip shooter takes longer to place all of the chips than the flexible placer takes to assemble the simple and complex integrated circuits. So, in this case, chips should be removed from the chip shooter and be placed on the flexible placer. But how many should be moved to the flexible placer? Determining the number requires algebra, and to understand how to do it, we need a numeric example.

Let’s do an example. In an assembly line, the “gate” in the cycle time is component placement.

- The chip shooter (CS) places passives at 60,000/hr and Simple ICs (SICs) at 4,000/hr

- The flexible placer (FP) places Complex ICs (CICs) at 3,000/hr and SICs and passives at 8,000/hr

- The bill of material (BOM) is 354 passives, 12 SICs, and 4 CICs

- If the FP takes less time to place the CICs and SICs than the CS takes to place all of the passives, then move some of the passives to the FP to time balance the line

- Let’s check the situation that the FP takes: (4 CICs / 3,000/hr) + (12 SICs / 8,000/hr) = 0.001333 + 0.0015 = 0.002833hrs

- The CS takes: 354/60,000/hr = 0.0059hrs

- So, move chips to the FP—but how many? Let’s call the number x. The times should be equal, so:

- 0.002833+x/8000 = (354-x)/60,000. Solve for x to time balance the line.

- 0.002833+x/8000 = (354-x)/60,000, multiply each side by 60,000

- (60,000*0.002833) + (60,000x/8000) = 354 – x

- 170 + (60/8)x = 354 – x, gather x terms

- 170 + ((60/8) +1)x = 354, gather numbers

- (68/8)x = 354-170 = 184, solve for x

- x = (8/68)*184 = 21.65 or 22 passive moved to FP

Let’s see if the times on each machine are the same.

- CTCS= 332 passives/60,000 passives/hr =0.005533 hrs or 19.92 secs

Is the FP the same?

- CTFP = 0.002833 + 22/8,000 = 0.005583 hrs or 20.10 secs

Why the difference?

The times can’t be exactly the same as we rounded the number of passives moved to the FP.

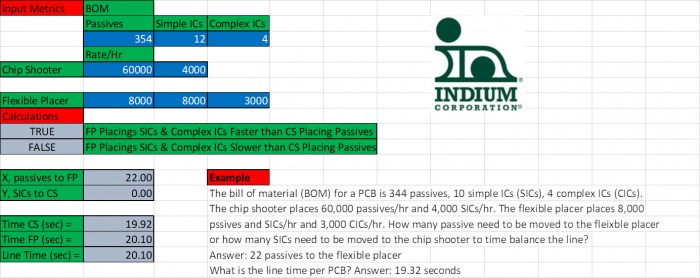

Figure 1 shows the calculations from the Excel® software tool I developed called "Line Balancer." Note theanswers are the same. If you would like a copy, send me an email at [email protected].

Figure 1. The "Line Balancer" answer to the problem

Here is a problem for you to solve:

- The chip shooter (CS) places passives at 50,000/hr and Simple ICs (SICs) at 3,000/hr

- The flexible placer (FP) places Complex ICs (CICs) at 4,000/hr and SICs and passives at 7,000/hr

- The bill of material (BOM) is 390 passives, 14 SICs, and 6 CICs

How many components need to be moved, and to which placement machine? What is the cycle time?

To the first person that sends me the answer, I will send them a Dartmouth hat.

Cheers,

Dr. Ron