In this report by the National Renewable Energy Laboratory (NREL), ITO (indium tin oxide) is proven to be more resistant to moisture than aluminum doped ZnO (AZO).

“As you know, PV modules are expected to last 25-30 years, and depend on moisture barrier plastic encapsulation to protect both the TCO and absorber layer from moisture degradation.

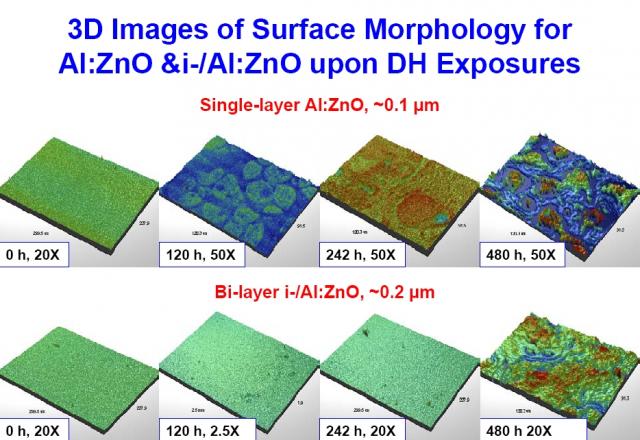

Moisture absorption in the TCO layer increases the resistivity of the TCO, which directly correlates to a reduction in power output of the module. The degradation process occurs over time and depends on temperature and humidity exposure, time in service, TCO type and thickness so there is no established moisture level that can be cited that will causes problems; the power output just linearly declines.

Moisture can enter the TCO by means of a lamination failure or directly through the plastic lamination over many years since no plastic is a perfect moisture barrier.

The case for using ITO simply is that if moisture does penetrate, ITO will degrade less than AZO.”*

Feel free to share your take on the report and what may be learned from it.Do you think the industry will shift from AZO to ITO based on moisture sensitivity or other concerns?

*A special thanks to Jim Slattery (Indium) for sharing this report and his thoughts.