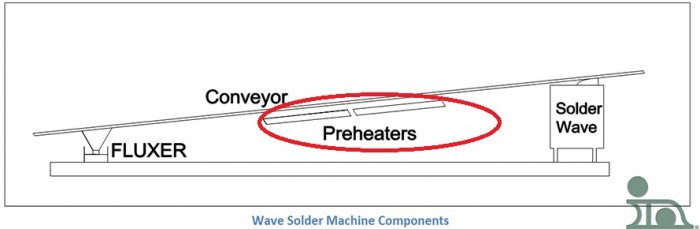

As a follow up to my post on quartz plate preheaters for wave soldering, this post isdedicated to the very similar quartz tube preheater. If you remember, one of the advantages of using a quartz plate was that ithad one of the fastest response times; however, quartz tubes have even faster response times.

The heating elements are placed inside the quartz tubes along with the thermocouples. The tubes can be quite fragile and, if items fall on them, they are likely to crack or break. One advantage, however, is that each tube can be turned on or off individually. This is beneficial if they are installed parallel to the conveyor because they will provide even heat no matter how wide the board is. If the conveyor system has a fixed width, they can be mounted perpendicular to the rails and be switched on or off individually to provide the required amount of preheat. If your wave soldering machine has the option for an automated and computer-controlled system, or has a fixed width, then these versatile preheaters are what you would want to use. It is common to couple the quartz tubes with hot air by either forcing heated or ambient air through the tubes. This is one of the more attractive options for technicians who do not have excess space in which to place a preheater.

My next post will discuss TWO types of preheaters: lamp-type infrared and ceramic plate.

*This is the seventh post in a twelve-piece mini-series entitledPreheating. This mini-series which is part of a larger program calledWave Soldering (A Segmented Synopsis).