Several years ago, Carol Gowans was interviewed by Kalwinder Kaur for an article which appeared on AZO Materials’ website. The full article can be found here. Although the article is almost 5 years old, the content continues to be relevant to today's needs. Here is an excerpt from that article:

“Question: Indium metal seems to play a part in so many cutting edge technologies. Why is this?

Answer: Although indium metal has been in commercial use for less than 100 years, many of today’s electronics now rely on its unique properties.

Indium-tin oxide is used to coat the touch-screen display glass on our smart phones, flat panel displays, tablets, and other electronics because it is both electrically conductive and transparent.

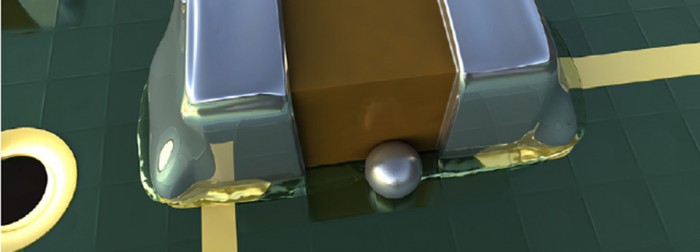

Indium metal is also thermally conductive. With a thermal conductivity of 86W/mK, indium has become very popular for thermal management in many of the electronics devices that have become such an integral part of our lives: mobile phones, tablets, and especially gaming equipment. As these devices become smaller and more powerful, thermal management becomes critical to ensure smooth operation.

In addition, indium compounds, such as indium trichloride, are used to make organic precursors that are used to build semiconductor layers for lasers, LEDs, and electronic circuits.”

The facts about indium hasn't changed over the years – the bulk thermal conductivity of indium will always remain at 86W/mK, but did you know that the thermal resistance of indium when used as an interface continues to decrease? That’s right: while thermal greases degrade over time, indium actually breaks in and continues to improve after time zero. If you’re interested in learning more about indium, stay tuned to this blog asI have more insights to share, or email me at [email protected].