Folks,

It's been a while. Let's look in on Patty……

Patty stared, bleary eyed, at her laptop screen. It was the day after the election. She and Rob were following the election closely as a “statistical thinking” exercise. They had met at a conference with The Professor in late October and agreed that following the election would test their statistical thinking skills. They established beforehand that they would not discuss who they favored, just the data.

All agreed that Mitt Romney had a greater challenge than President Obama.

As Rob said, “Of the six most populated states, even the Republicans agree that Obama will win California (1), New York (3), Illinois (5), and Pennsylvania (6). Romney is only a shoe-in for Texas (2). Only Florida (4) is a toss up”

“I thought some analysts were saying that Pennsylvania is in play,” The Professor commented.

“They’re dreaming,” Patty said with conviction. “Pennsylvania has too many big cities; typical democratic strong holds,” she continued.

“Many pollsters have 255 electoral votes in Obama’s column and only a little over 200 for Romney. It’s hard to see a Romney path to victory. It is statistically unlikely he could win all of the swing states” Rob added.

The Professor beamed as he listened to his protégés' intelligently analyze and argue the situation.

They all agreed that it was hard to understand why many were referring to it as a close race, although voter turnout could change everything.

As election night went on, Patty felt she could call the election at 8PM EST. However, she was sympathetic that the networks needed a high level of certainty. The major networks were finally calling it at 10PM. When they did, Romney was ahead in the popular vote by about 1 million. Patty chuckled to herself, when a renowned TV anchor commented that it might be a governing challenge to Obama to win the electoral college and not the popular vote. Clearly he had not factored in the fact that, although California was “called” for Obama around 10PM EST, it was called with only a few percent of the votes in. The networks were using exit polls and statistical analysis to make a projection. By the time all of the west coast votes were counted, Obama will comfortably win the popular vote – because of California’s large population. Patty thought this should be obvious to the pundits.

Patty had stayed up until about 11PM to watch the results. It was comforting that her analysis was spot on. However, she was so “wound up” that she couldn’t fall asleep and she was now paying the price.

As her attention shifted back to the email she was writing.

Suddenly, she was jarred by a loud, cheerful voice.

“Hey kiddo, pack your bags, looks like we’re on the road again,” Pete said loudly.

As usual Patty thought,” How does Pete always know these things before I do…..I’m the boss!”

“What’s the scoop?” Patty asked.

“Remember our facility in Ohio? They are having wave soldering yield and throughput problems,” Pete answered.

“What!” Patty shouted. “We spent a lot of time there six months ago optimizing their wave soldering operation and teaching them the appropriate use of solder preforms. What happened?” She finished.

“Not sure,” Pete responded. “I thought we worked really well with their team and developed a good process. It seemed to me it was one of the more productive projects I was involved in in quite awhile,” Pete finished.

“And you didn’t even offend any of the senior managers,” Patty teased.

Pete chuckled but his cheeks did turn a little red. Pete was a terrific process engineer, but he had a little bit of a “short fuse,” although he was usually right.

“In talking to some of my buddies there, they told me that senior management hired a very senior fellow who is considered an expert in wave. Strangely, things fell apart right after he joined,” Pete explained.

“Well, you are on your own for this one. I've got a number of family commitments over the next two weeks,” Patty said with a little sadness in her voice. Patty enjoyed these types of challenges.

“As soon as I get the official request, you’ll be on your way,” Patty said.

“Oh, and don’t offend anyone,” she teasingly finished.

As Pete left her office, she checked her emails. Sure enough, there was a note from Mike Madigan asking her to intervene in this wave soldering problem.

Two days later Pete was in ACME’s Ohio facility sitting in the office of Pam Olinski, the site's quality manager.

“Pete, I’m so glad you could come. Three months ago our wave soldering first pass yield was 95% and our production was about 2,000 boards per day. Yield is now 90% and production is off 15%. “Help!” Pam said.

“Tell me about the new guy?” Pete asked.

“Fred Castle; he has very impressive credentials, but he has been running the wave process like a dictator. He stops the process a lot to adjust the wave machine. I think he will be offended that you are here to audit the process,” Pam finished.

Because of this concern, they agreed that it might be best to have Pete initially view the process from afar. So, they decided that Pete would be given an operator’s smock and walk around the shop floor for half a day or so.

As Pete arrived on the shop floor, almost immediately he saw Fred stop the wave machine and make some adjustments. While making the adjustments, Fred held a board in his hand – and he looked at occasionally. After the wave machine was running again, Pete saw that Fred looked carefully at every board.

Pete saw one of the wave operators was going on a break. Pete remembered Molly Stark from his visit to optimize the wave process six months ago, so he stopped her and ask if she could join in for lunch.

The morning passed quickly, and Pete was off to lunch with Molly. As Pete had suggested, Molly brought another operator, Chuck Petrus to lunch. Pete insisted on treating, so Molly and Chuck left their brown bags behind.

In total, Fred stopped the line four times during the almost 4 hours of Pete's observations. Each time he made adjustments on the wave machine. After exchanging pleasantries Pete asked, “Why was that fellow stopping the wave line so often?”

Molly got quite animated and answered, “That’s Fred Castle, the supposed wave genius. He stops the line every time there is a defect and adjusts the wave machine parameters. A number of us complained to him that he shouldn’t make adjustments on the machine that with just one fail. That’s what you taught us.”

“What did he say?” Pete asked.

“ ‘I’ve forgotten more about wave soldering than you will ever know’……No one has said a word since,” Chuck responded.

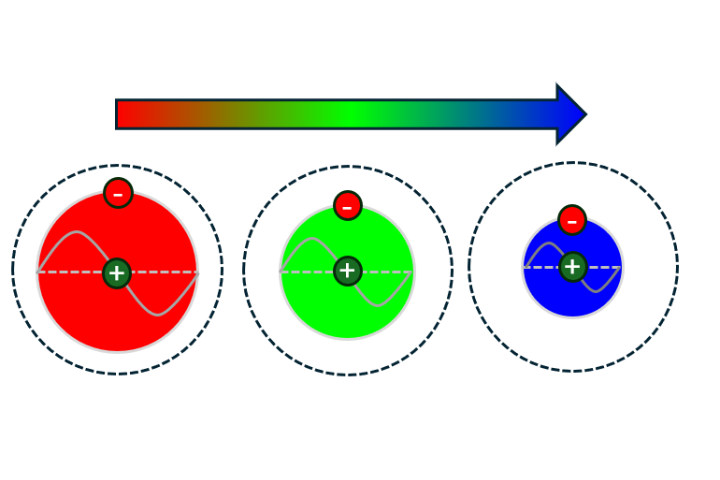

“You and Patty taught us about special cause and common cause variation. I don’t think Fred understands that,” Molly commented.

“He’s also a knob twiddler,” Chuck added.

Does Fred know the difference between common and special cause variation? Is that the root of the yield and throughput problems?

What is a knob twiddler? Stay tuned to find out.

Cheers,

Dr. Ron