Peter writes,

Dear Dr. Ron,

I am trying to implement the Pin-in-Paste (PIP) process. The PWB is 63 mils thick, the component pin diameter is 47 mils, the PWB hole diameter is 87 mils, and the PWB pad diameter is 120 mils. I used the Indium Corporation Software StencilCoach™, and the result said that I needed a stencil aperture with a 416 mil diameter for the 5 mil thick stencil I was using.

That stencil aperture diameter is way too big. What gives?

Best,

Peter

Dear Peter,

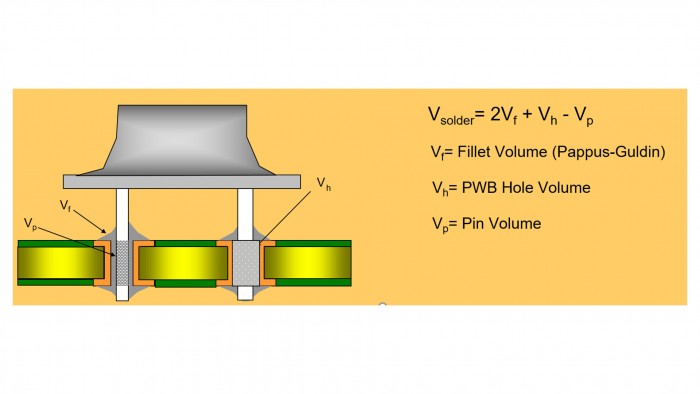

The issue is that your PWB hole diameter is too large. It is 40 mils greater than the component pin diameter. This situation results in a very large amount of solder required to fill the mostly empty PWB hole. See Figure 1. Since solder paste is about 50% by volume flux, quite a bit of paste is often needed to form a good solder joint.

Figure 1. This figureis a cross-section schematic of a component mounted on a PWB. The fillet, hole, and pin volumes are shown and the resulting solder volume needed. If the component pin is much smaller than the PWB hole diameter, more solder paste will be needed than the pin-in-paste printing process can provide.

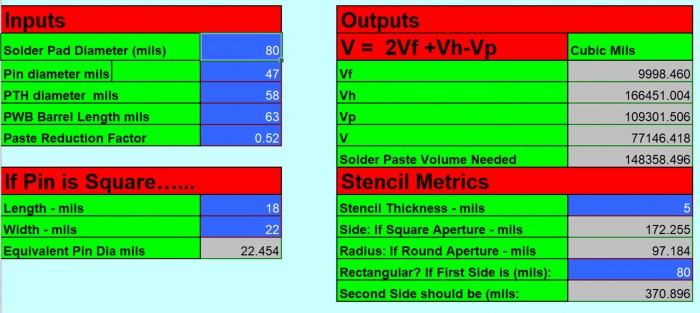

Chatting with my friends, Jim Hall and Phil Zarrow of ITM and Jim McLenaghan of Creyr Innovation, they all recommend that the PWB hole diameter be in the range of 10 to 12 mils larger than the pin diameter. In your case, this would be a hole diameter of 58 mils (I chose 11 mils greater than the pin diameter) and a PWB pad diameter of say 80 mils. StencilCoach™ calculates that a stencil aperture diameter of 194 mils is required, see Figure 2. It might be better to choose a square aperture of 172 mils on a side as seen in the StencilCoach™ output. If this size stencil aperture is still too large, solder preforms can help. I will discuss using them in a future post.

Figure 2. The right hand column of this figure shows that a round stencil aperture diameter of 194 mils (2 x 97.184, the third cell from the bottom) is requiredto form a good solder joint in this application. It might be advantageous to use a square aperture of 172 mils on a side, as show in the fourth cell from thebottom in the right column.

By the way, Jim McLenaghan refined some earlier work that resulted in the formula for the fillet volume used in StencilCoach™. Zarrow and Hall just released a book calledTroubleshooting Electronic Assembly: Wisdom from the Board Talk Crypt. These three folks are some of the most knowledgeable people in electronics assembly today.

Cheers,

Dr. Ron