Thermal Interface Materials (TIMs)

Phase-Change Metal Alloy (PCMA) TIMs

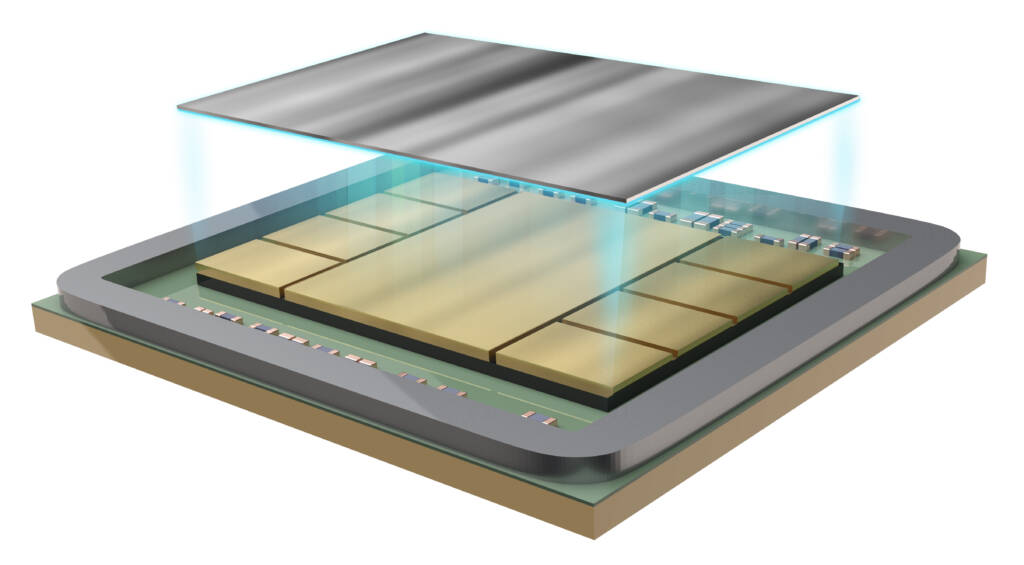

Metals conduct heat and electricity through their valence electrons, a highly efficient mechanism that applies to both solid and liquid forms of metals and alloys. In addition to their naturally high thermal conductivity, liquid metals also feature low interfacial resistance, enabling them to dissipate heat quickly. Indium Corporation’s PCMA TIMs are engineered to provide exceptional thermal conductivity and reliability, making them ideal for both TIM0 (TIM1.5) and TIM1 applications.

Powered by Indium Corporation

- High Thermal Conductivity

- Pure Metal TIMs

- Liquid Phase During Operational Hours

Product Overview

Low Melting Point Metal Alloys

PCMA TIMs are thermal interface materials that are solid at room temperature. With a low melting temperature range (50°C–108°C), they are designed to become liquid or pasty during operation, enhancing heat transfer by filling in surface gaps.

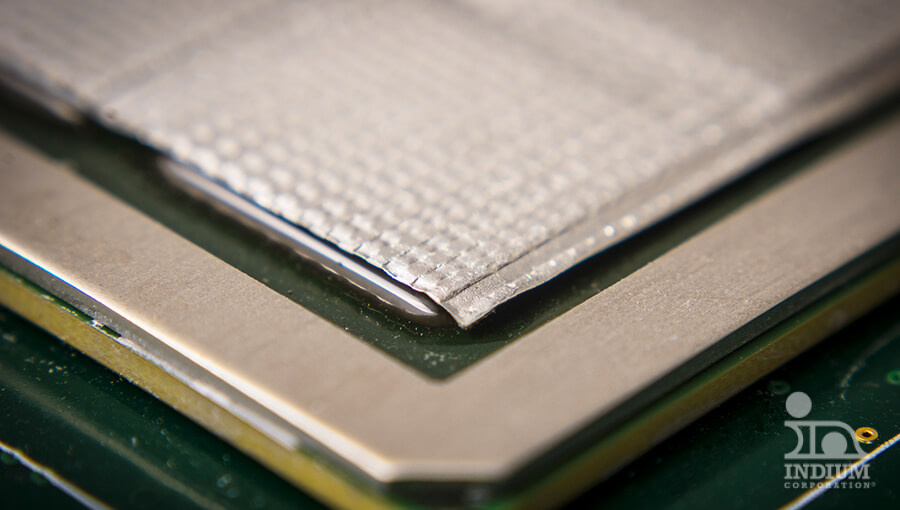

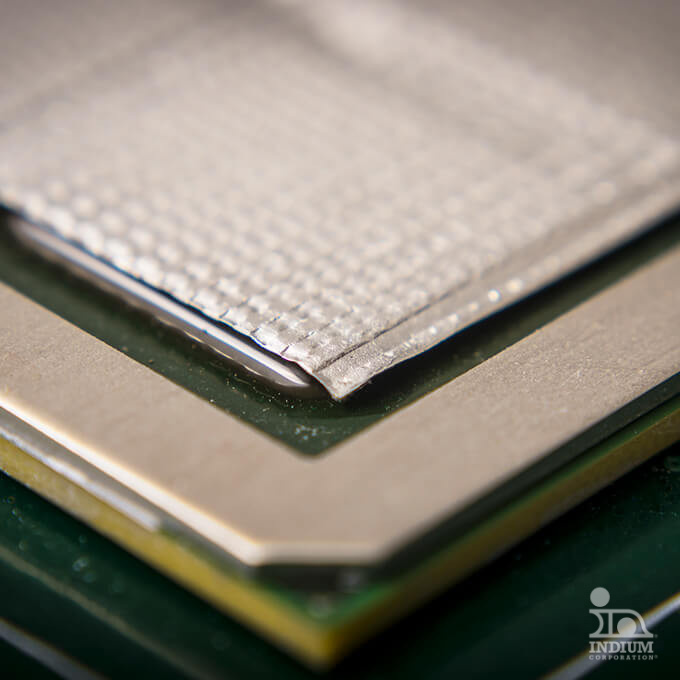

Barrier Material

Since PCMA TIMs will be in a liquid/paste phase during operational hours, there should be a barrier designed that will prevent leakage of those materials.

Thickness Recommendation

The minimum thickness for most alloys is 50 μm, but the recommended thickness for certain applications will depend on the specific warpage of the die (for the semi-conductor applications) and potential CTE mismatch between the surfaces connected with PCMA TIM.

TIM Set Up

If there is any warpage in the package (curved die), it is highly recommended to do a burn-in step with PCMA TIM (70°C for at least 30 seconds). Recommended pressure for PCMA TIMs is between 30 and 40 PSI.

Features

The thermal performance of PCMA TIMs is similar to that of liquid metal TIMs, but PCMA TIMs offer several distinct advantages.

Phase Change Metal TIMs Products

There are 2 types of PCMA TIMs:

Non-Gallium Containing PCMAs

| PCMA | Phase Change Temp (°C) | Thermal Conductivity (W/mK) | Contains Ga? | Manufacturability | Oxidation | Surface Planarity | Reliability |

|---|---|---|---|---|---|---|---|

| PCMA2305 | 60-72 | 18.4 | N | EASY | GOOD | GOOD | GOOD |

| PCMA2305+ | 58-65 | 18.4 | N | EASY | GREAT | GOOD | GOOD |

| Indalloy® 19 | 60 | 19.6 | N | EASY | BAD | BAD | BAD |

| PCMA2 | 71-76 | 22.6 | N | EASY | GOOD | GOOD | GOOD |

| Indalloy® 162 | 72 | 29 | N | EASY | OK | GOOD | OK |

| Indalloy® 174 | 79 | 10 | N | OK | OK | OK | OK |

| Indalloy® 27 | 81 | 12 | N | OK | OK | OK | OK |

| Indalloy® 224 | 108 | 44 | N | EASY | GOOD | GOOD | GOOD |

| Indalloy® 1E | 118 | 41 | N | EASY | GOOD | GOOD | GOOD |

| Indalloy® 281 | 138 | 16 | N | OK | OK | GOOD | GOOD |

| Indalloy® 290 | 143 | 73 | N | EASY | GOOD | GOOD | GOOD |

| Indalloy® 4 | 157 | 86 | N | EASY | GOOD | GOOD | GOOD |

Related Applications

PCMA TIMs are available for use in a variety of applications.

Immersion Cooling

A technique on the rise for thermal…

Related Markets

Indium Corporation PCMA TIMs is suitable for a wide range of markets.

Expert Support for Reliable Results

Do you have technical questions or sales inquiries? Our dedicated team is here to help. “From One Engineer to Another®” isn’t just our motto—it’s our commitment to delivering exceptional service. We’re ready when you are. Let’s connect!

Looking for Safety Data Sheets?

Access everything you need — from technical specifications to application guidance — in one convenient location.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.