In electronics assembly, the soldering process is fundamental to creating reliable connections. Traditionally, this involves high reflow temperatures, often exceeding 240°C. However, as components become smaller, more complex, and increasingly sensitive to heat, the industry is shifting toward alternative methods. One of the most promising solutions is low-temperature soldering.

This guide will provide a comprehensive overview of low-temperature soldering, exploring its benefits, key applications, and the critical role of specialized alloys. We will focus specifically on bismuth-containing solder, a key player in this evolving landscape. By the end, you’ll understand why this technology is more than just a trend—it’s a necessary evolution in modern electronics manufacturing.

What is Low-Temperature Soldering?

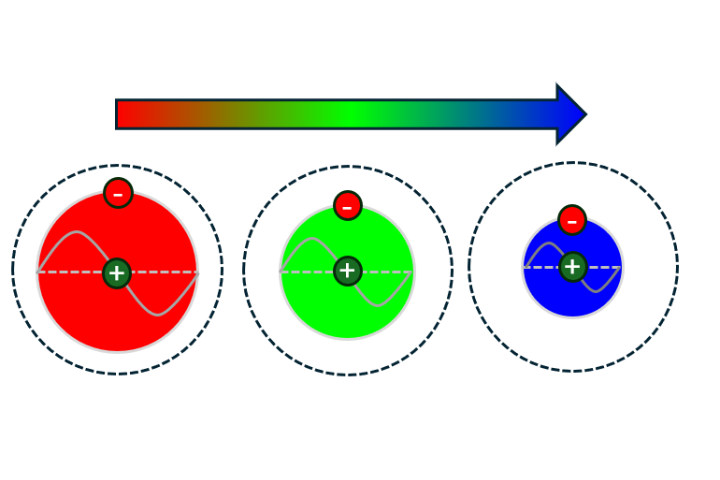

So, how low is “low temperature” in soldering? Generally, any soldering process that uses a peak reflow temperature below 180°C is considered low temperature. For comparison, conventional lead-free solders, such as tin-silver-copper (SAC) alloys, typically require peak temperatures between 230°C and 250°C.

The primary enablers of this process are specialized alloys designed to melt at lower points. The most common metals used to achieve these lower melting points are indium and bismuth. While indium-based alloys are highly effective, offering excellent ductility and thermal conductivity, this guide will concentrate on the growing importance of bismuth-containing solders due to their unique properties.

Why Does Lower Temperature Matter?

Reducing reflow temperatures offers significant advantages that address some of the biggest challenges in electronics assembly.

- Reduced Component Stress: Many modern components, such as temperature-sensitive sensors, optical devices, and certain plastics, cannot withstand the high heat of traditional reflow processes. Low-temperature soldering minimizes the risk of thermal damage, improving yield and reliability.

- Mitigation of Warpage: Large, complex packages like ball-grid arrays (BGAs) are prone to warpage at high temperatures. This deformation can lead to critical defects, including head-in-pillow (HiP) and non-wet opens. By lowering the peak reflow temperature, you can substantially reduce warpage, ensuring more reliable solder joints.

- Energy and Cost Savings: Lowering oven temperatures directly translates to reduced energy consumption. Over thousands of production cycles, this can lead to significant operational cost savings, making the manufacturing process more sustainable. On top of cost savings, manufacturers using reduced peak reflow temperatures are able to reduce their yearly CO2 emissions.

- Enabling Step Soldering: Low-temperature alloys are perfect for step-soldering processes. In this technique, components are soldered in multiple stages, starting with high-temperature solders and moving to lower-temperature ones. This allows for the assembly of complex boards without disturbing previously soldered components.

The Power of Bismuth-Containing Solder

Bismuth is a key element in creating effective low-temperature solder paste. When alloyed with tin, it creates a eutectic alloy with a melting point significantly lower than traditional SAC solders. The most common bismuth-tin alloy, Bi58Sn42 (Indalloy®281), melts at 138°C. This makes it an ideal choice for applications where heat sensitivity is a major concern.

Advantages of Bismuth-Based Alloys

- Lead-Free: Bismuth is a lead-free material, helping manufacturers comply with global environmental regulations like RoHS.

- Low Melting Point: With a melting point around 138-140°C, bismuth-containing solder allows for peak reflow temperatures as low as 160°C. This drastic reduction protects sensitive components and minimizes thermal stress across the entire assembly.

- Good Tensile Strength: Bismuth alloys offer good tensile strength, creating robust solder joints capable of withstanding certain types of physical stress.

Considerations and Challenges

While bismuth is a powerful tool, it’s not a universal solution. One of its primary characteristics is its brittleness. Bismuth-based solder joints have lower shear strength and are more susceptible to failure under drop shock or heavy vibration. Sounds challenging, right? This is why these alloys are generally not recommended for devices that are frequently dropped, like mobile phones.

However, advancements in alloy composition, such as the addition of silver, have helped mitigate some of this brittleness, making the solder easier to work with. Choosing the right low-temperature solder paste requires a careful evaluation of the application’s specific needs, including the final product’s operating environment and reliability requirements.

Common Applications for Low-Temperature Soldering

The benefits of low-temperature soldering make it suitable for a wide range of applications across various industries.

Consumer Electronics

The assembly of temperature-sensitive components like micro-electro-mechanical systems (MEMS), camera modules, and plastic connectors benefit greatly from lower processing heat.

LED Lighting

LEDs are highly sensitive to heat, and excessive temperatures during assembly can degrade their performance and lifespan. Low-temperature soldering ensures that the LEDs remain undamaged, preserving their brightness and reliability.

Optics and Photonics

Precision optical components, such as lenses and sensors used in communication and imaging systems, can be damaged or misaligned by the thermal stress of high-temperature reflow. Lower temperatures help maintain their structural integrity and performance.

Choosing the Right Low-Temperature Solder Paste

Selecting the right solder for your application involves more than just looking at the melting point. Here are a few key factors to consider:

- Operational Temperature of the Device: Will the final product be exposed to high temperatures during its use?

- Component Sensitivity: What is the maximum temperature your most delicate component can withstand?

- Mechanical Stress Requirements: Will the product be subjected to drops, vibrations, or thermal cycling?

- Metallizations: What surfaces are you soldering to? Compatibility is key to a reliable joint.

For example, if you are soldering two surfaces with different coefficients of thermal expansion (CTE), an indium-based alloy might be a better choice due to its superior ductility. It can absorb the stress from different expansion rates without cracking. On the other hand, if the application is not subject to high mechanical shock, a bismuth-containing solder is an excellent option.

The Future is Cool

Low-temperature soldering is no longer a niche technology; it is rapidly becoming a mainstream solution for the challenges of modern electronics manufacturing. By reducing thermal stress, mitigating warpage, and saving energy, it offers a path to creating more reliable and sophisticated electronic devices.

While bismuth-containing solder presents some challenges, its benefits—particularly its low melting point—make it an indispensable material for many applications. As alloy formulations continue to improve, we can expect to see its adoption grow even further.

If you’re exploring ways to improve your assembly process or protect sensitive components, it’s time to consider the advantages of turning down the heat.