Applications

Electroplating

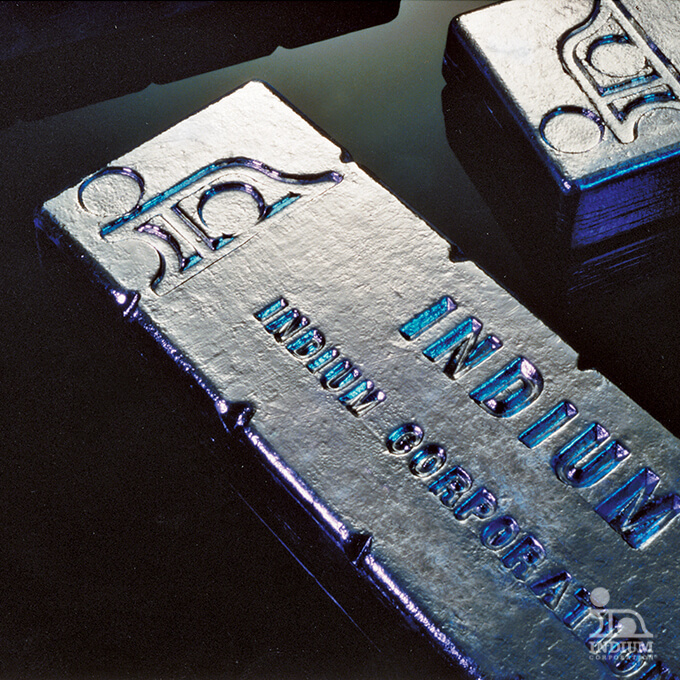

Electroplating is a process that uses an electric current to deposit a thin layer of metal onto the surface of a substrate. This technique is commonly used to enhance the appearance, corrosion resistance, or wear resistance of an object. The process involves immersing the substrate and a metal electrode in an electrolyte solution. Indium Corporation provides both the plating bath chemistry and indium metal anodes for electroplating indium layers.

Overview

The Benefits of Indium Electroplating Materials from Indium Corporation

Indium-electroplated films have many industrial applications that take advantage of the unique physical and chemical properties of the indium metal, such as its low melting point, low vapor pressure, inherent softness and malleability, cold welding properties, anti-friction properties, and alloy hardening properties. And our expertise in the manufacturing and application of indium started in 1928.

Benefits

High-Purity and High-Quality Guaranteed from Indium Corporation’s Extensive Experience with Indium

Extensive Expertise

Our extensive expertise in manufacturing and supplying indium helps us provide high-quality materials and support to our customers.

High-Purity

We offer high-quality, high-purity materials in various shapes or forms.

Related Applications

PCB Assembly

Proven and cutting-edge materials for PCB assembly…

Related Markets

Indium electroplating applications include surface preparation, decorative finishing on metals and plastics, sealing, aircraft bearings, and electrical interconnects.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.