Folks,

The service temperature for electronics in a modern automobile can be higher than 125C. These high temperatures raise the concern of copper-tin intermetallic growth in solder joints.

Often, we don’t think about the fact that even room temperature is a considerable fraction of the melting temperature of tin, e.g. 293K/505K = 0.5802. A reminder that we have to use the Kelvin scale when making these calculations. However, 125C is 0.788 of the way to tin’s melting point. This temperature is the equivalent of a blacksmith’s wrought iron being at 895C. Figure 1 shows a blacksmith’s forge temperaturechart. Note that 895C is beyond red hot.

Figure 1. A Blacksmith’s forge temperature chart

So, what is SAC solder's copper-tin intermetallic growth at 125C as a function of time? Fick’s law of diffusion tells us that the growthof the intermetallic, D, is given by:

D = (k(T)t)^0.5 Eq 1.

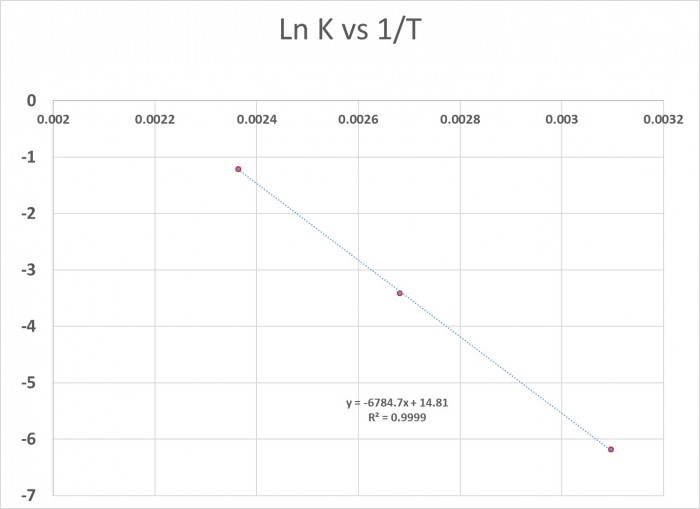

Where k(T) is a temperature dependent growth rate constant and t is time. Siewert etal[i] performed experiments in which D was measured for various temperatures and times for SAC solders. Following Siewert’s lead I will use time in hours. By using their data in their Figures 2a through 2c for SAC solder, I was able to plot k in an Arrhenius graph, see Figure 2.

.

Figure 2. An Arrhenius Plot of Siebert’s Data

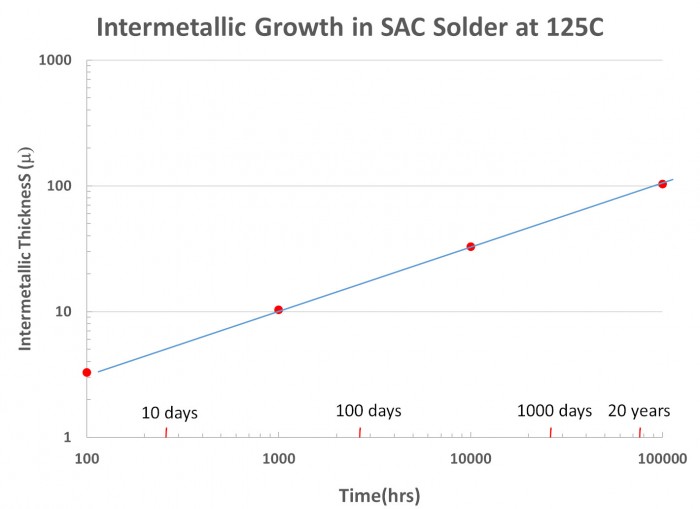

From Figure 2, we see that Ln k = -6784.7/T+ 14.81 or k = exp (14.81)*exp-(6784.7/T). So, at 125C or 398K, k = 0.1068. Using this value of k, we can plot D as a function of time. The results are in Figure 3. Note that both scales are logarithmic. In 1,000 hrs (42 days) the intermetallichas grown 10 microns. In 3 years, it hits 53 microns. We should be cautious, as Siewet'sdata has error bars. But, my sense is that these projections are within a factor of two.

Figure 3. Intermetallic Growth as a Function of Time at 125C in SAC Solder.

What is the effect of these thick intermetallics in a harsh auto environments? No one knows, but I would encourage someone to perform some experiments to find out.

Cheers,

Dr. Ron

[i] Siewert, T. A. etal, Formation and Growth of Intermetallics at the Interface between Lead-Free Solders and Copper Substrates, APEX 1994.