At times, I get questions like, "How long does it take to deposit 20 µmof Indium on my plate using your Indium Sulfamate Bath?" Well, the answer to this question would make it very easy for the customer. Let me show you how tocalculate this with ease.In this post, I will derive a simple and easy relation that will work for anyone. Believe me, it's easy; just use some fundamental relations that we studied in high school. It starts with how many electrons you require to reduce an In3+ ion to an In atom – 3, right!

So, how much charge is that – 3e!

The time it takes directly depends upon how much charge we've got to supply to reduce all those Indium ions, and at what time rate we can supply those – that is “current”!

If you’ve heard of this famous current-charge relation, i =q/t,yes, that is what I am talking about.

So, getting back to the basics,

If the cathode (where the Indium is electrodeposited) is not 100%efficient, it will take a little longer. Let’s say, σ be the efficiency. Then it will take, 1/σtimes longer. For example, if it is50% efficient, it will take, 1/0.5 = 2times longer. So, incorporating efficiency, the equation for time becomes:

Time to plug in all these values in the equation above, you get:

Okay, so the answer is, the estimated time to deposit20 µmis 34 minutes, and you know what factors can change this.

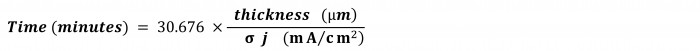

And here’s an easy formula to calculate time in minutes for the most widely used units of thickness and current density;

Okay, why not call this number 30.676 “Shital’s Inplate constant”!

Indium Sulfamate Bath from Indium Corporation has a cathodic efficiency of 90%. More efficiency means less time! The typical current density to work on is around 10-20 mA/cm2but it can be increased up to100 mA/cm2, maintaining the bath temperature at 20-25°C. Increasing the current density from20 mA/cm2to100 mA/cm2can reduce the deposition time by a factor of 5,i.e. the same 20µm will now deposit in 7 minutes.

The extensive use of indium plating today dates back to the 1930s when the founders of Indium Corporation developed a commercial indium plating bath for the first time. Recent developments in semiconductor technology and flip-chip bonding utilize indium to create interconnects between layers of wafers. Indium is electroplated onto wafer substrates to create high-density, low-pitch and high-aspect ratio indium bumps. The softness, ductility and wettability of Indium ensure a strong and reliable connection between two surfaces, even if they are not perfectly flat or aligned. Furthermore, Indium exhibits stability even at temperatures approaching zero, making it highly suitable for use in semiconductor applications that operate in extreme environments, such as those encountered in space.

If you are thinking of small-scale electroplating projects, including the restoration and repair of antique metal items with Indium coating, you can start with a wholesome easy-to-use electroplating kit like the one offered here.

Please refer to the following documents to learn more about indium electroplating, Indium Sulfamate Bath, and indium bump electroplating.

- Achieving a Finer Grain Structure Using the Indium Sulfamate Plating Bath

- Indium Bump Electroplating of Wafers Using Pulse Plating

- Plating, an Alternative Method of Applying Indium

- Proper Surface Preparation for Indium Plating

- Prototype Plating Using Indium Sulfamate Plating Bath

- Reclamation & Disposal of Indium Sulfamate Plating Bath Solution

And any other inquiries, please contact me.