Folks,

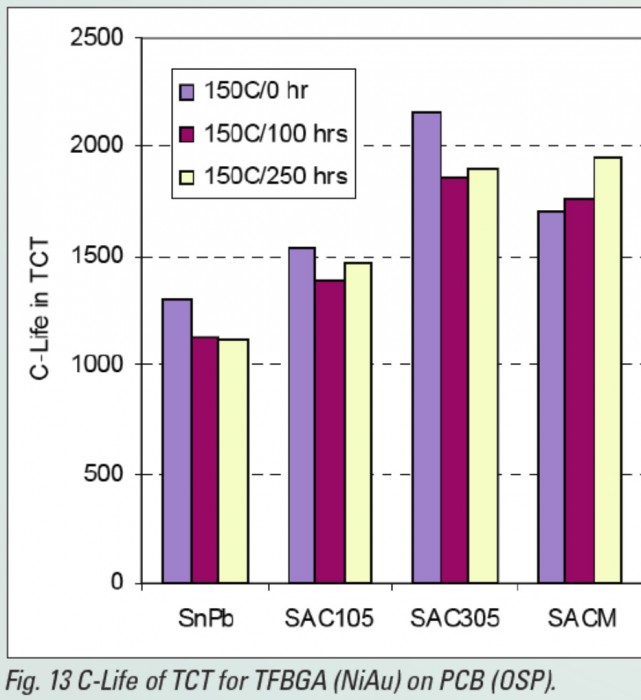

In our last post, I discussed that, contrary to popular belief, intermetallic compounds (IMCs) formed in soldering processes are not necessarily brittle. I reviewed some literature that indicated that failure modes are usually at interfaces between the IMCs themselves, the IMCs and the copper or solder and often in the bulk solder itself. The perspective that IMC growth may not significantly affect reliability is also supported by work performed by Lee, et al. Figure 1, from Lee’s paper, shows that agingfor 250 hrs at 150°C does not significantly affect characteristic life in thermal cycle testing.

Figure 1. Aging for up to 250 hours at 150°C did not significantly affect characteristic life in thermal cycle testing in Lee's referenced paper.

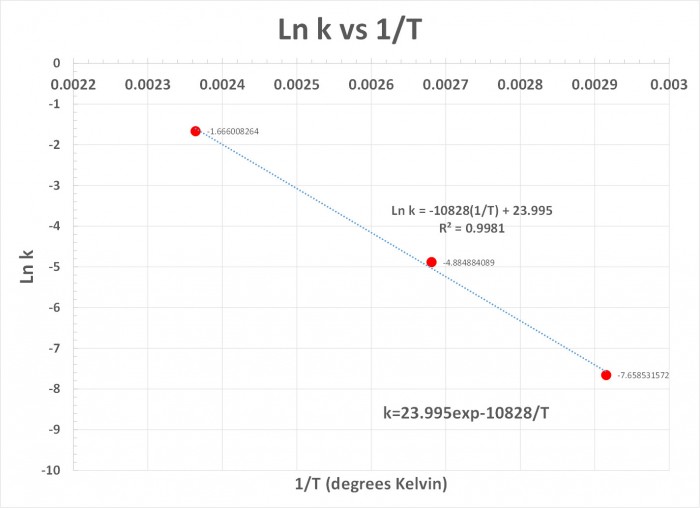

However, it would be prudent to minimize the thickness of IMCs. So this raises the question:how quickly do IMCs grow at any given temperature?Work performed by Siewert,et al[i] holds the answer. In this paper, Siewert supported past work that the thickness of IMCs grows as X=(kt)0.5and added new data to support modeling using this equation.In this equation,X is IMC growth distance, k is a constant dependent on temperature, and t is the time. One might expect that X is strongly dependent on temperature (T) and it is. Using data from Siewert’s paper, I was able to generate values of k as a function of T and plot them in an Arrhenius plot. See Figure 2.

Figure 2. An Arrhenius plot for k.

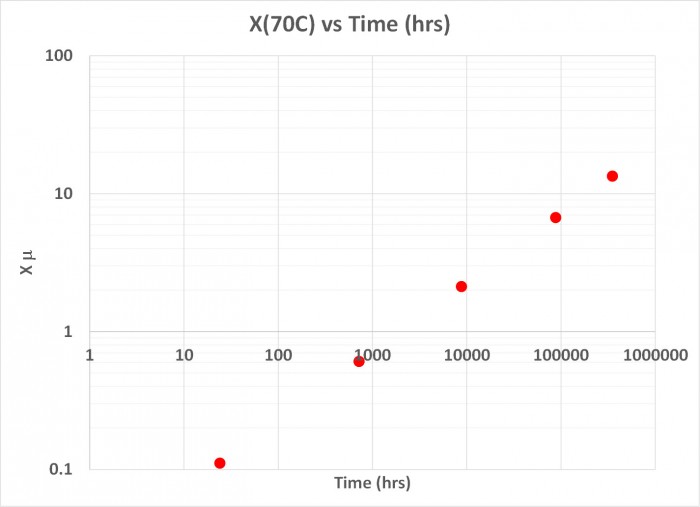

I next used Figure 2 to obtain a value of k at 70°C and plotted the IMC growth X in microns as a function of time in hours. The result is in Figure 3.

Figure 3. IMC grow as a function of time at 70°C.

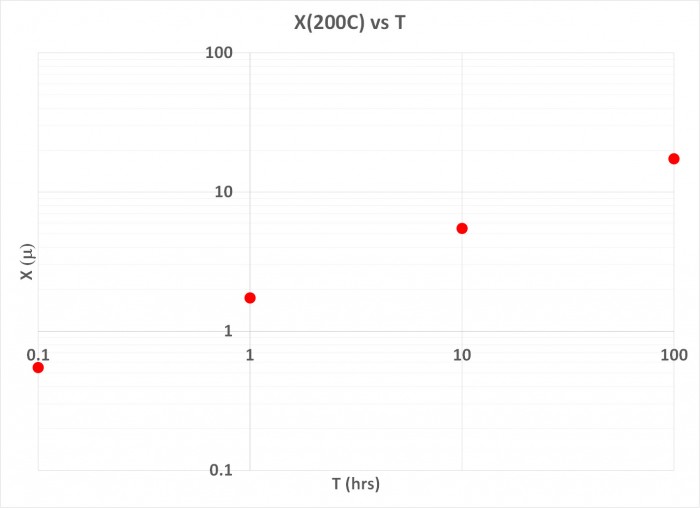

Note that about 40 years are required to obtain a little over 10 microns of growth. Figure 4 shows the results for IMC growth at 200°C. In this case, only 100 hours are required to obtain about 10 microns of growth. So going from 70 to 200°C produces an acceleration factor of over 30,000 in the effectiveIMC growth rate to 10 microns.

Figure 4. IMC growth as a function of time at 200°C.

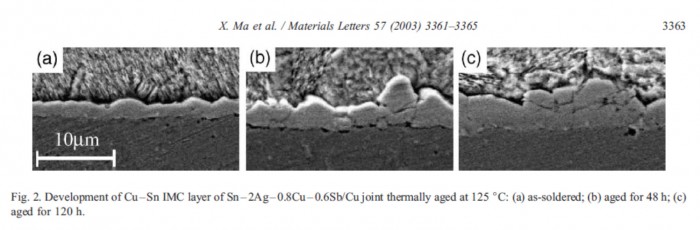

These are theoretical calculations from data collected at different temperatures. Let’s see if the formulas work in real life. In another paper [ii]by Ma, et al. his team aged some solder joints at 125°C for 120 hours. The equations used above would predict IMC growth of 2.2 microns under these conditions. From Figure 5, we see about 2 microns of growth consistent with the calculation estimate.

Figure 5. Images from Ma's paper of IMC growth at 125°C for 120 hours.

So although IMCs are not that brittle, it is wise to limit their growth. Hence, limiting exposure to very high temperature aging is wise, but certainly minimizing solder rework is advisable,as the molten solder enables very fast IMC growth.

Cheers,

Dr. Ron