Folks,

I thought I would take a stab at listing the minuses, pluses, and “it’s a wash” aspects of assembling with lead-free (LF) solder.Here are my first thoughts.Please tell me what I missed or disagree.

Cheers,

Dr. Ron

Minuses

1. Pb-Free requires higher reflow temperatures

The Tm for LF solders, in the 217-229C range, has created numerous challenges:

a. PWB warpage and damage

b. Component damage

c. New defect modes such as graping and head-in-pillow defects (although concurrent reduction in solder paste deposit sizes for 0201 and 01005 passives and 0.3 mm CSPs also exacerbate these defects)

d. Defects related to increased oxidation

e. Increases in voiding

f. Increases in tombstoning

2. The higher cost of LF solder, mostly for wave soldering

a. It’s not just the silver, tin is much more expensive than lead

3. Poorer wetting of LF solders, creating the most significant challenges in wave soldering

4. More rapid copper pad dissolution on PWBs in wave soldering

5. LF solder attack of wave solder machine components

6. LF reliability in harsh thermal cycle testing appears poorer than tin-lead solders

7. Tin Whiskers

It’s a Wash

1. Short-term reliability in consumer product-type environments

2. Protection of the environment if discarded products are improperly disposed of

a. Lead in electronics has never been shown to cause a problem in land fills

3. Since July 2006, about $3 trillion of products have been manufactured with LF solder, with no “the sky is falling”-type of problems

Pluses

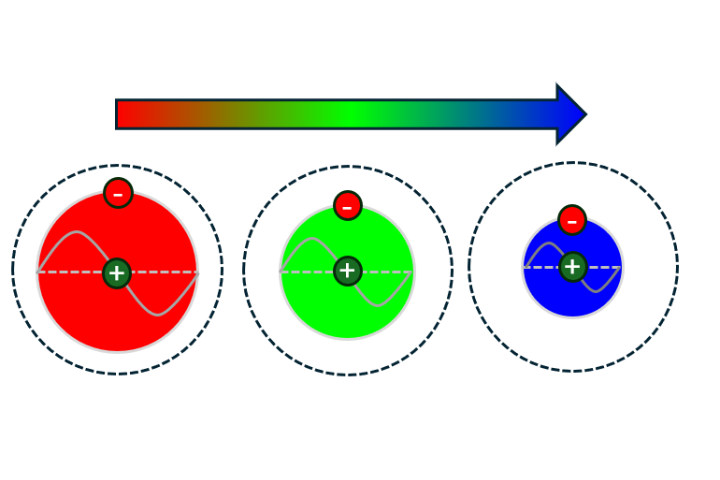

1. LF solder's poor wetting enables finer lead spacings (see photo Courtesy of Motorola)

a. It may be argued that some modern electronic products (e.g. smartphones) could not be made with tin-lead solder

2. It is safer to recycle LF solders, especially if performed in a non-controlled environment

OK – your turn. Please comment.