Two categories of solder are available to choose from when the in-service environment for a device reaches above 125°C either in continuous operation or thermal cycling accelerated life testing.These categories are those comprised primarily of lead, and those of gold.From the electronics industry’s drive to eliminate lead, many manufacturers who have traditionally used lead solders are treading cautiously, looking now at the gold solders, primarily at Indalloy 182 (80Au20Sn).

The most common concern regarding this switch relates to the strength of AuSn, which is much higher than the lead solders.The degree that this should be of concern however, should be realized within the scope of the application.

For instance, review this case scenario:

Indalloy 159 (90Pb10Sn) was used in a device for years to adhere high temperature sensors to a calibration probe that is slowly cycled in operation from 350K (~75°C) to 500K (~225°C).The solder joins a nickel and gold plated Kovar™, or platinum or platinum coated, nickel lead to a tinned copper lead.The solder joint is not placed under tension or shocked.

Considering the high temperature solder options in this scenario, the AuSn would be mechanically preferred.

Why?

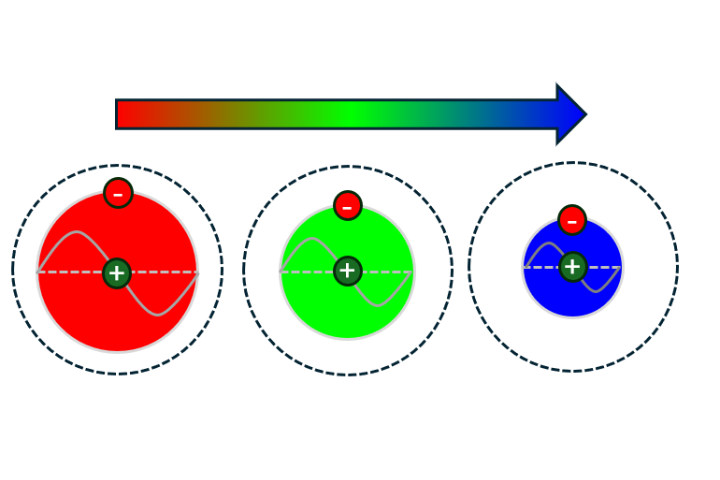

Well, tin-bearing soft solders will leach gold from gold metallizations during soldering, creating a brittle Au-Sn intermetallic layer within the solder joint.The more gold available, the more consumed, and the greater the thickness of the resultant intermetallic layer.The brittle nature of this layer, situated intimately next to the relatively soft PbSn solder layer, creates differential stresses that promote crack propagation upon thermal cycling.

AuSn was not considered previously because the engineers were familiar with its hardness and, given the cracking failure described using a softer solder, they did not anticipate improvement.It was a pleasant surprise to them to find that switching to a lead-free solder would not sacrifice the quality of their device.AuSn is a brittle alloy but, unlike the description above, no differential stresses are involved.

Note: Eutectic gold solders have been used for many years to solder nickel plated Kovar™ lids to high reliability ceramic packages and have a good history of fatigue performance.