Applications

Hot Bar Soldering

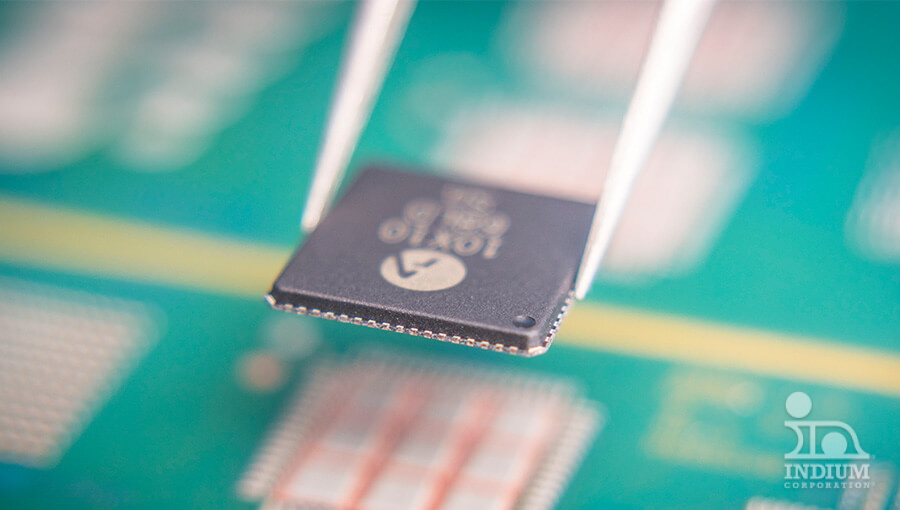

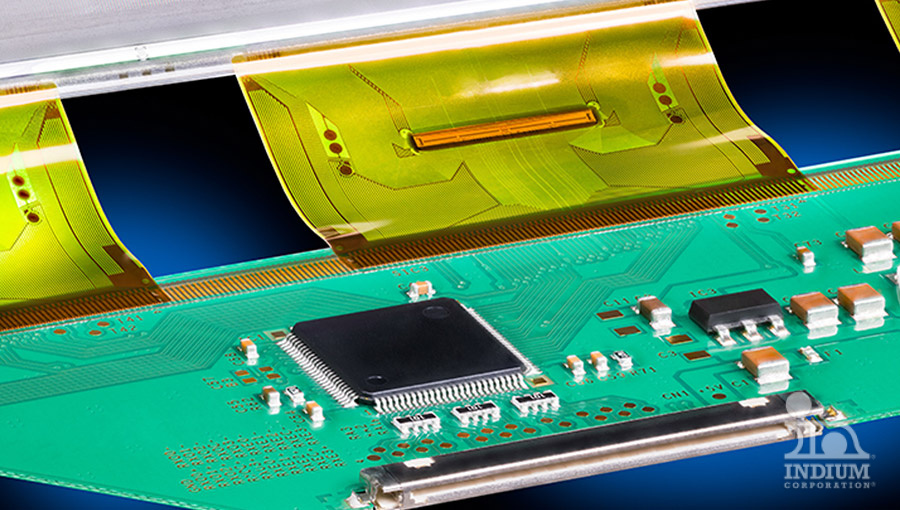

Hot bar soldering is a crucial technique in electronics assembly, enabling precise mechanical and electrical connections between flexible and rigid PCBs or components. This method is valued for producing high-reliability joints without requiring extra connectors. Successfully addressing the challenges of hot bar soldering, including sensitivity to environmental conditions, requires proven materials and specialized process expertise.

Overview

Revolutionizing Hot Bar Soldering with Reliable Solutions from Indium Corporation

Hot bar soldering is an increasingly popular method to attach flexible circuits to ridged circuit boards. Indium Corporation’s Durafuse® LT is a cutting-edge patented solder paste alloy system that enables lower-temperature hot bar reflow processes, yields stronger, more reliable solder joints, and improves sustainability compared to conventional SAC305 solder pastes or Anisotropic Conductive Film (ACF) materials.

Benefits

Unlock Cost-Efficient, Reliable, and Streamlined Solder Solutions

Efficiency and Cost-Effectiveness

Indium Corporation’s solutions reduce processing time and minimize the need for additional components, significantly cutting costs.

Enhanced Thermal Management

Our solders offer excellent thermal conductivity, which is crucial for maintaining the integrity of solder joints during high-temperature operations.

Improved Reliability

Our innovative flux and solder combinations provide consistent performance and durability, even under demanding conditions.

Simplified Assembly

The use of flux-free processes and precise application methods ensures clean, robust connections with minimal residue.

Related Applications

Related Markets

Hot bar soldering is essential in various markets, including telecommunications, consumer electronics, automotive, and industrial equipment. Its application is critical in manufacturing flexible printed circuits (FPCs), wire harnesses, and other components that demand high precision and reliability.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.