Applications

Indium Corporation’s extensive product range is utilized across a wide variety of industries and applications. Our cutting-edge solutions, known for high performance and reliability, are ideal for automotive electronic assembly, high-temperature soldering, power electronics packaging and assembly, and thermal management, among other areas.

Explore Common Applications for Our Products

See how our innovative materials are used across a wide range of variety of industries.

-

-

-

-

-

-

-

-

-

-

-

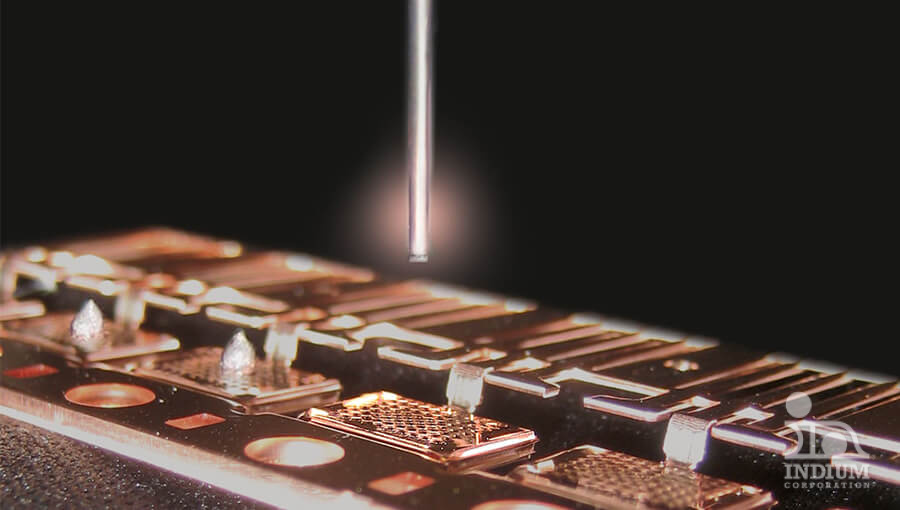

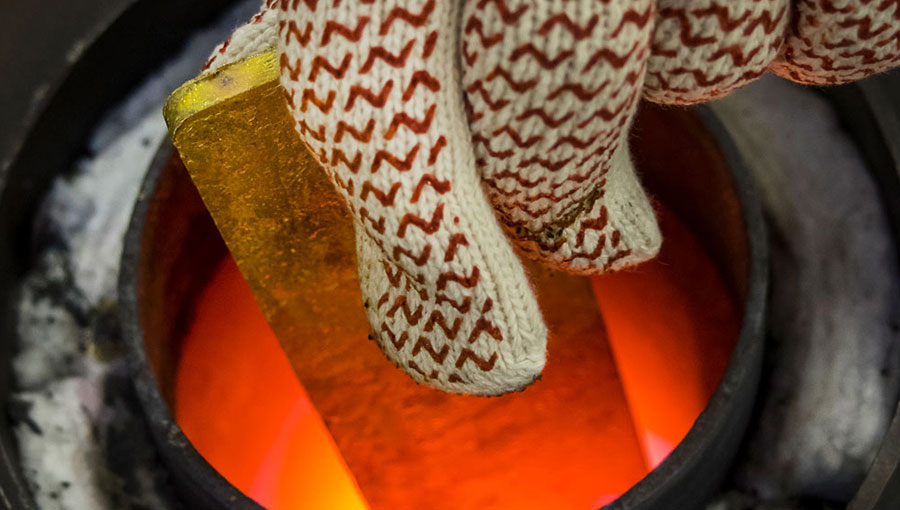

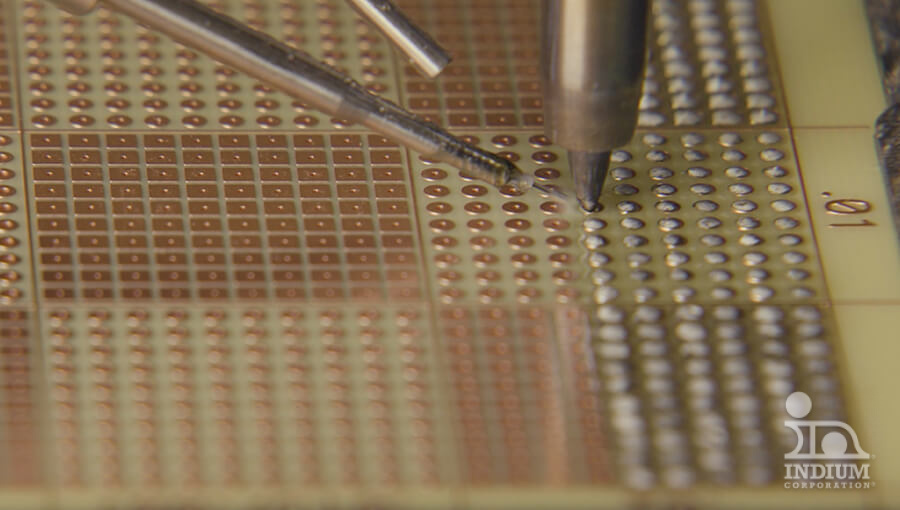

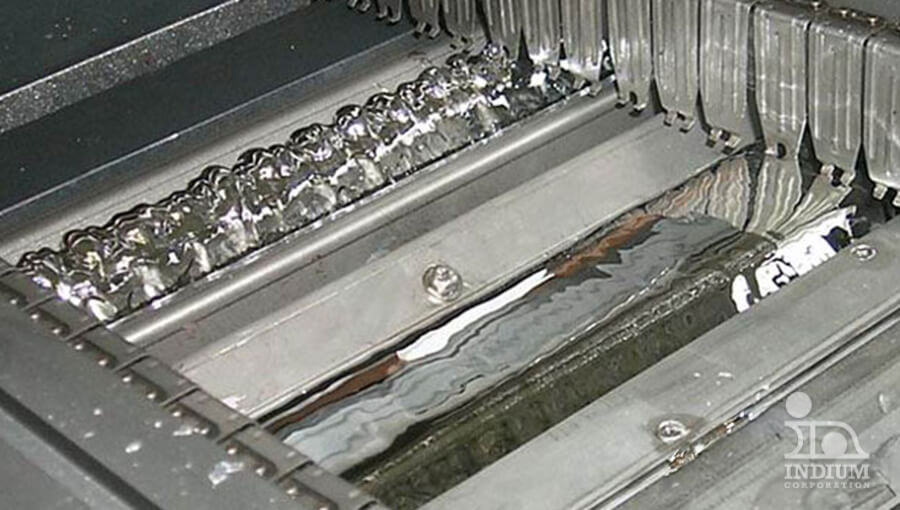

High-Temperature Soldering

Offering high-temperature soldering materials for critical applications…

-

-

-

-

-

-

-

-

-

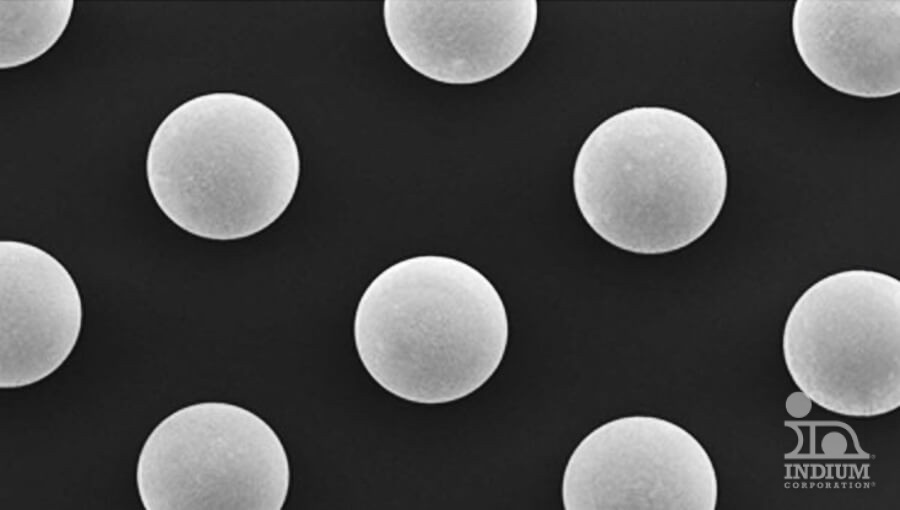

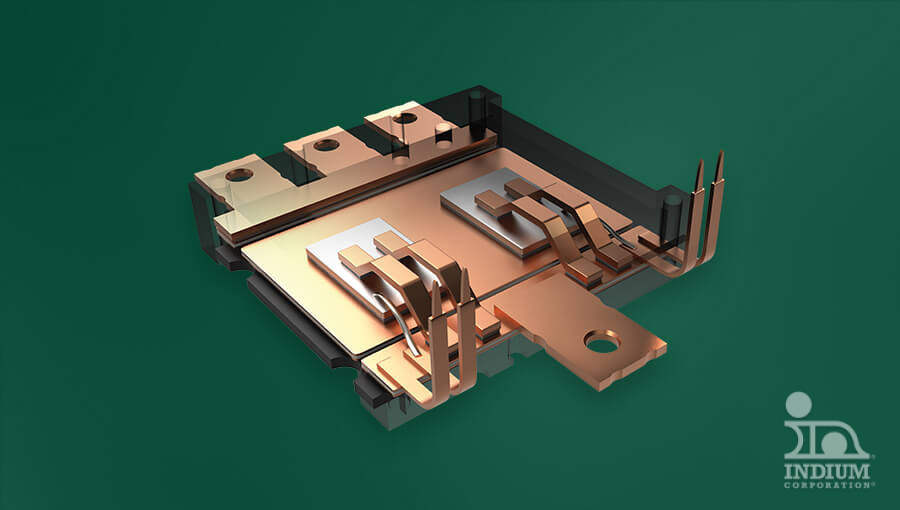

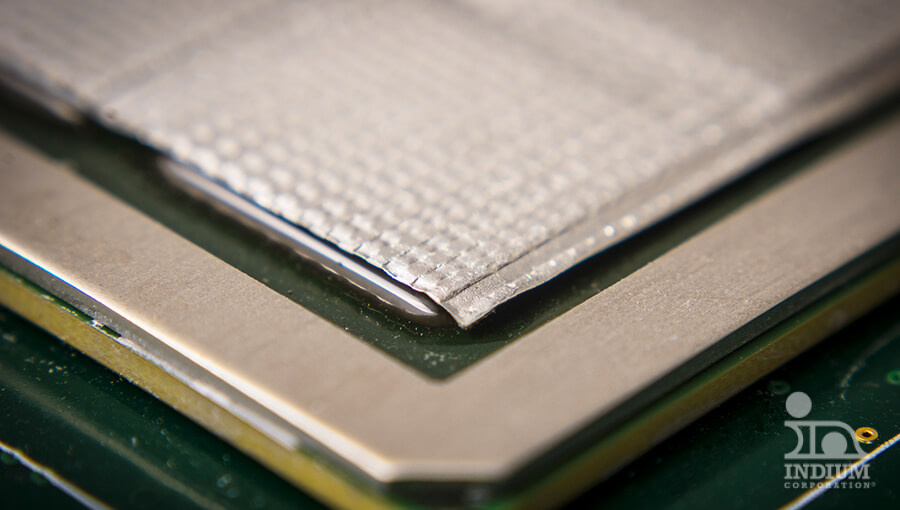

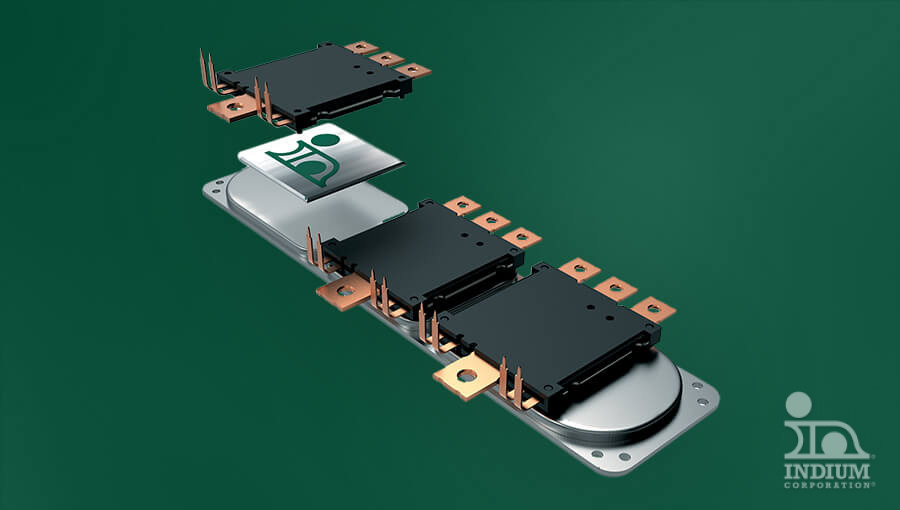

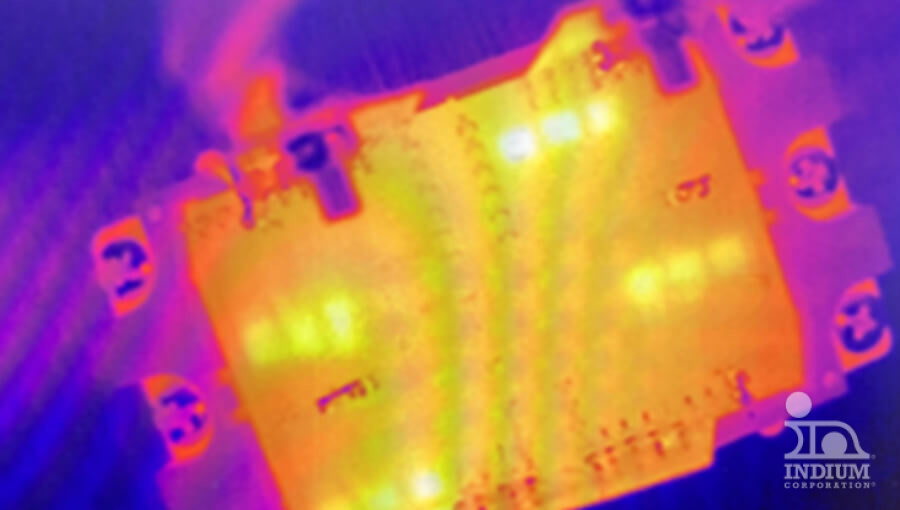

Power Electronics Packaging & Assembly

Extensive range of proven high-reliability solder and…

-

-

-

-

-

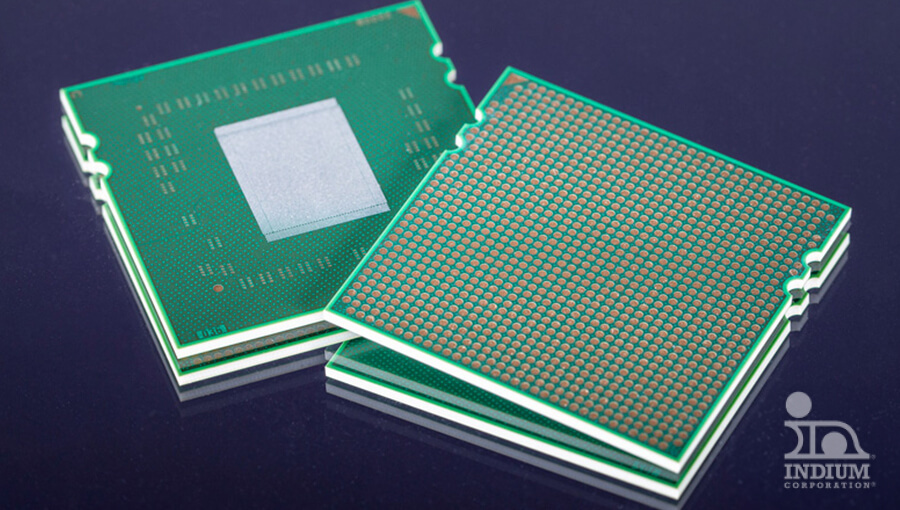

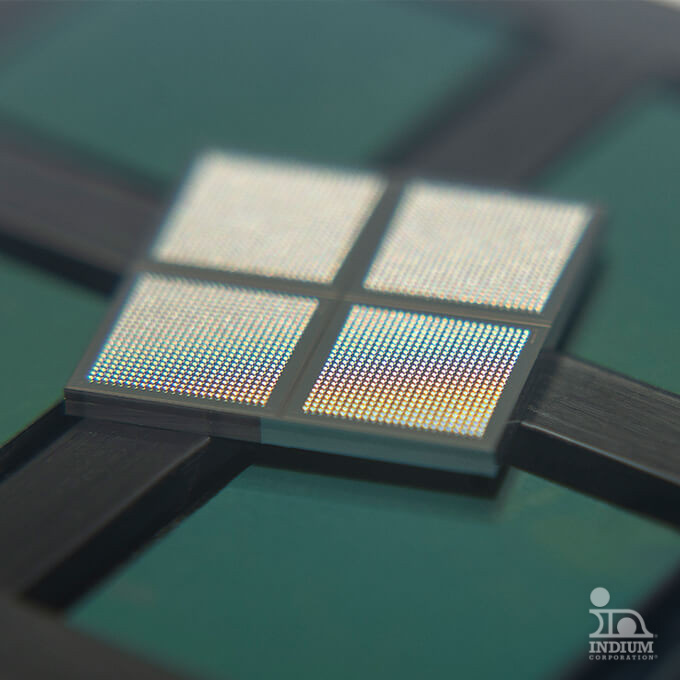

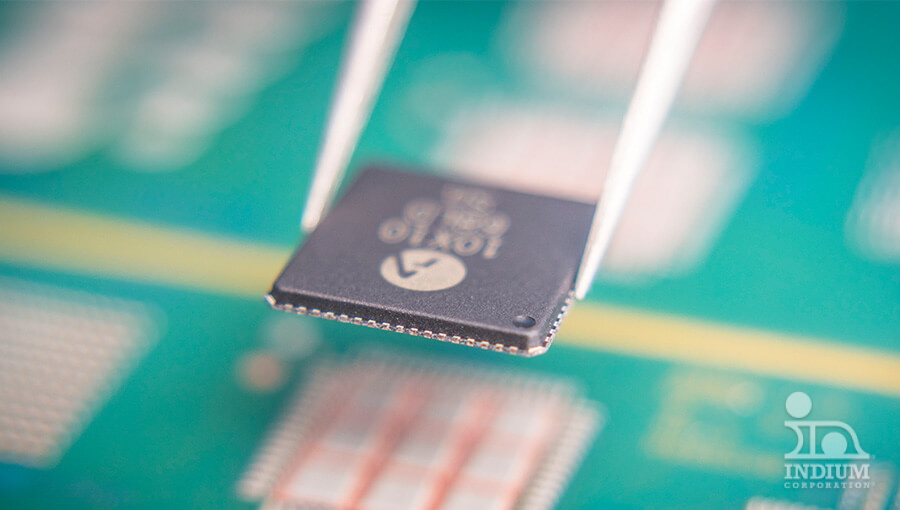

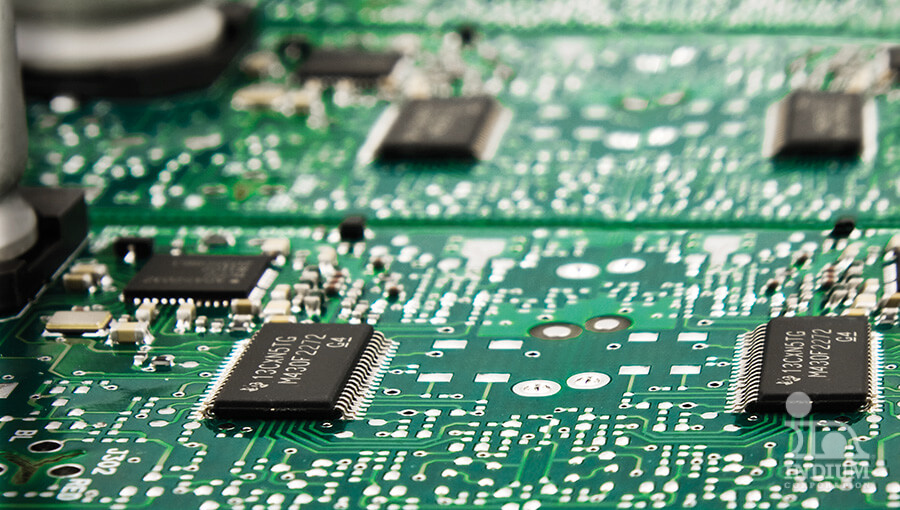

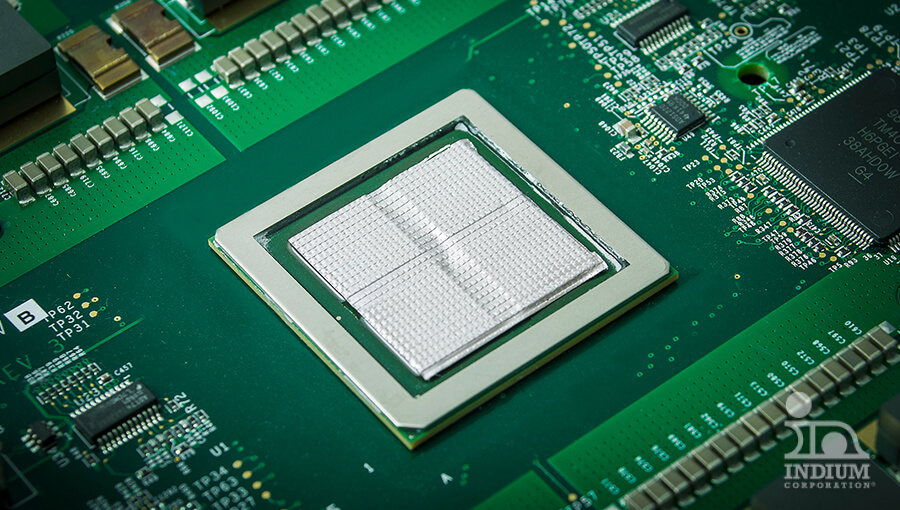

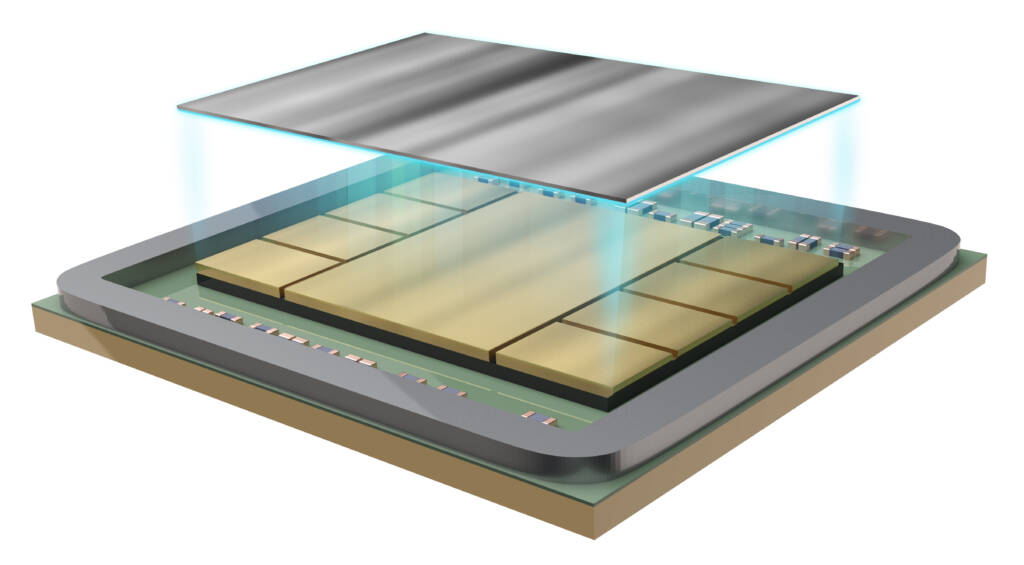

Semiconductor Packaging and Assembly

Critical semiconductor packaging ensures functionality and durability.

-

-

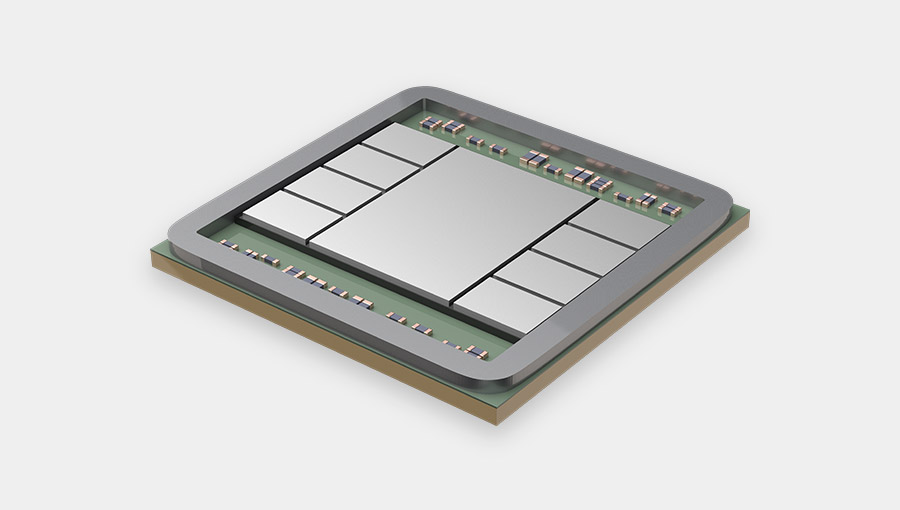

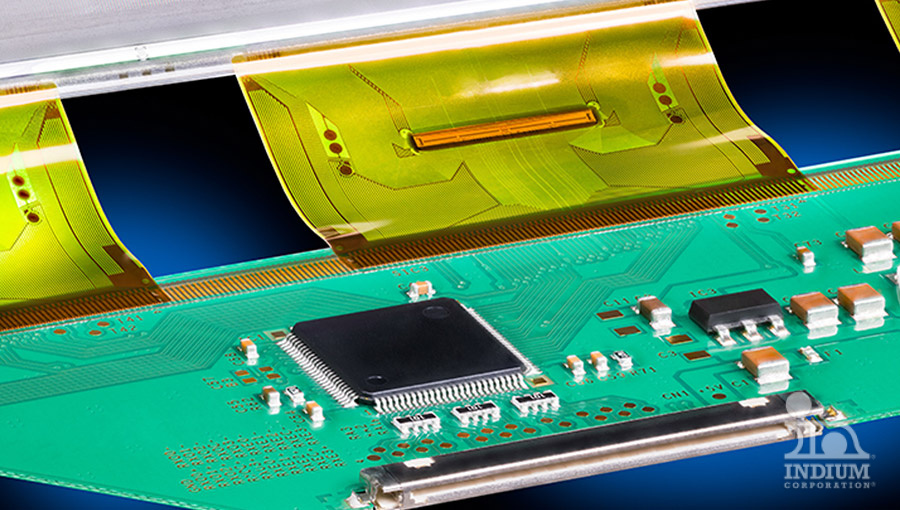

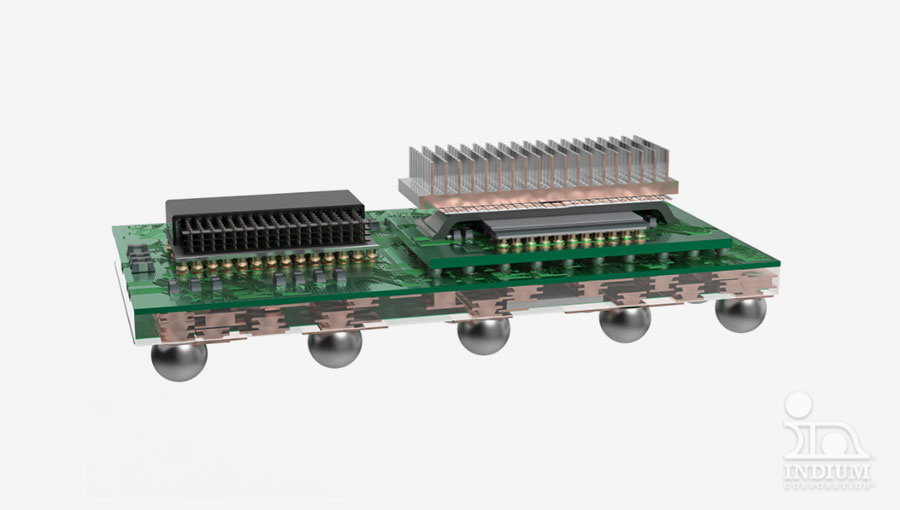

SiP and Heterogeneous Integration Assembly (HIA)

System-in-package (SiP) and heterogeneous integration solutions

-

-

Thermal Evaporation and PVD Coating

Achieve efficient and high-quality thin film deposition.

-

-

-

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.