Pressure Sintering

InFORCE®

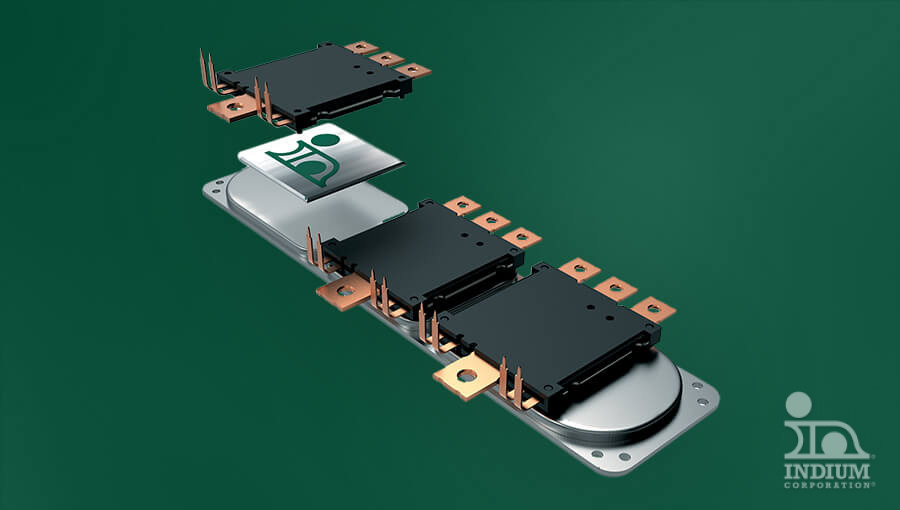

Indium Corporation’s InFORCE® Series of pressure sinter paste materials are available in Silver (Ag) and Copper (Cu), making InFORCE® the ideal solution for die-attach in power modules for demanding applications such as inverters used in EVs, charging stations and renewable energy. These materials deliver exceptional reliability and thermal efficiency, ideal for demanding applications like EV inverter and charger modules.

Powered by Indium Corporation

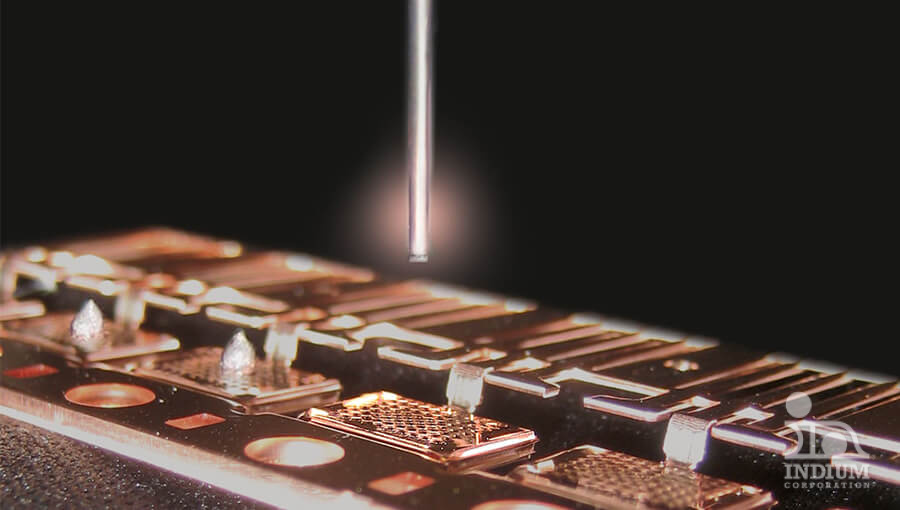

- Optimal Printing and Dry Placement

- High Metal Load

- Suited for Wide Band Gap Semiconductors

Product Overview

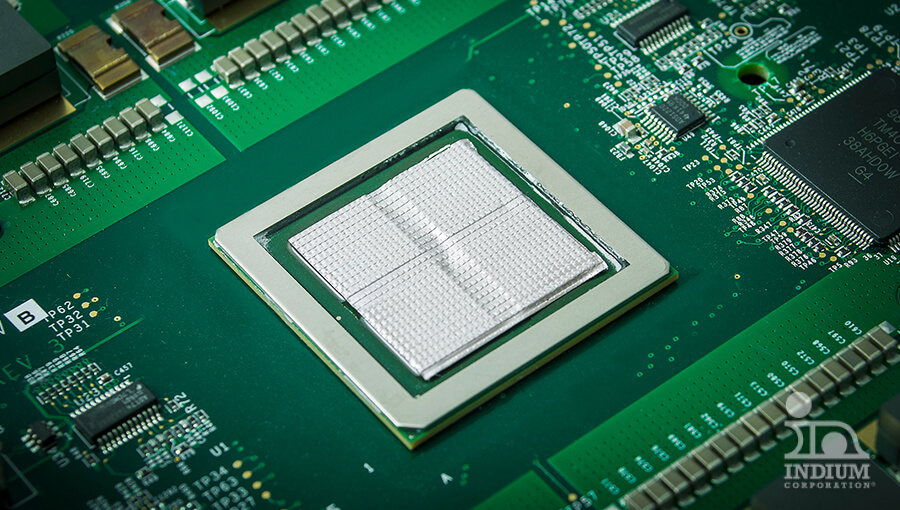

Thermal and Mechanical Reliability

InFORCE® sinter pastes provide low porosity, high-reliability die-attach interconnects. Expected die shear strength exceeds 50MPa, even after thermal cycling/thermal shock reliability test.

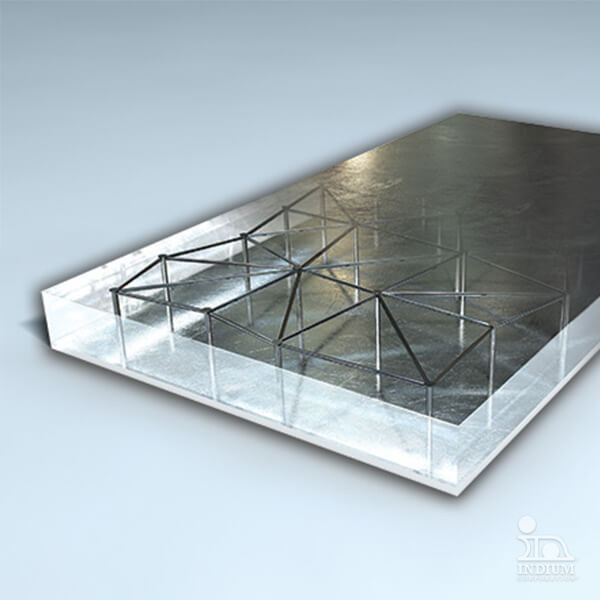

High Metal Load, Low Organic Content

InFORCE® sinter pastes are made with a higher metal content than other pressure sinter pastes, offering less material volume loss during processing. Process times can be shortened, especially drying, and the wet-to-post sintered bondline thickness (BLT) variability is minimal. Reduction in BLT from wet to post sintered is approximately 50%.

Quick Facts

Sintering for die-attachment in power electronics has become a standard process, particularly in EV inverter applications utilizing SiC semiconductors. InFORCE® sinter pastes provide material advantages from Ag or Cu interconnects while also enhancing process benefits.

InFORCE® Products

Designed for power electronics die-attach applications, these materials are also being considered for package attachment in power modules, enabling direct bonding to coolers or heat-sinks.

InFORCE®MF

InFORCE®29

| Product Name | Material | Metal Content | Application |

|---|---|---|---|

| InFORCE®MF | Silver (Ag) | 91% | Die-attach, dry placement |

| InFORCE®29 | Copper (Cu) | 85-87% | Die-attach, dry placement |

Product Data Sheets

InFORCE®MF Pressure-Assisted Ag Sinter Paste for Die-Attach PDS 100320 R1.pdf

Related Applications

The InFORCE® Series of products are suitable for a variety of applications.

Related Markets

InFORCE® sinter pastes are primarily designed for the EV market, targeting power electronics in inverter and charging applications. Pressure sintering for die-attach is rapidly becoming the preferred process, particularly in applications utilizing SiC semiconductors.

Expert Support for Reliable Results

Do you have technical questions or sales inquiries? Our dedicated team is here to help. “From One Engineer to Another®” isn’t just our motto—it’s our commitment to delivering exceptional service. We’re ready when you are. Let’s connect!

Looking for Safety Data Sheets?

Access everything you need — from technical specifications to application guidance — in one convenient location.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.