PCB Assembly Fluxes

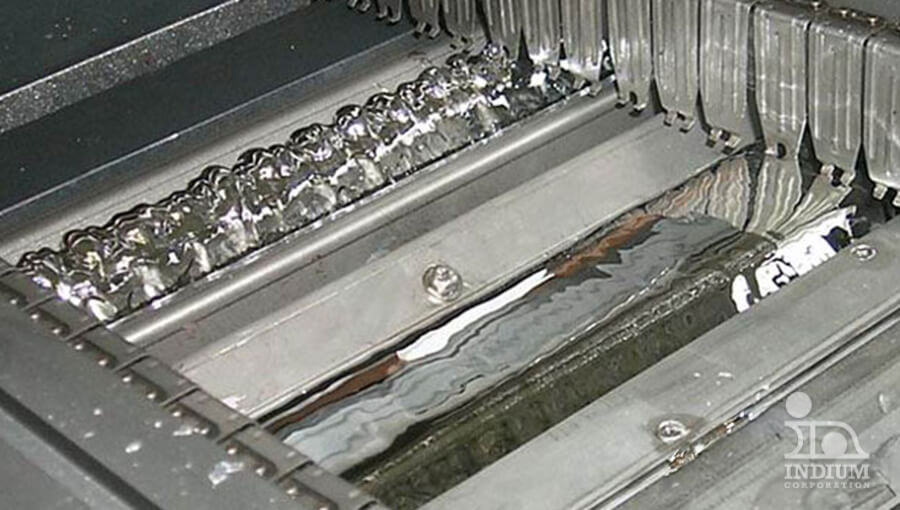

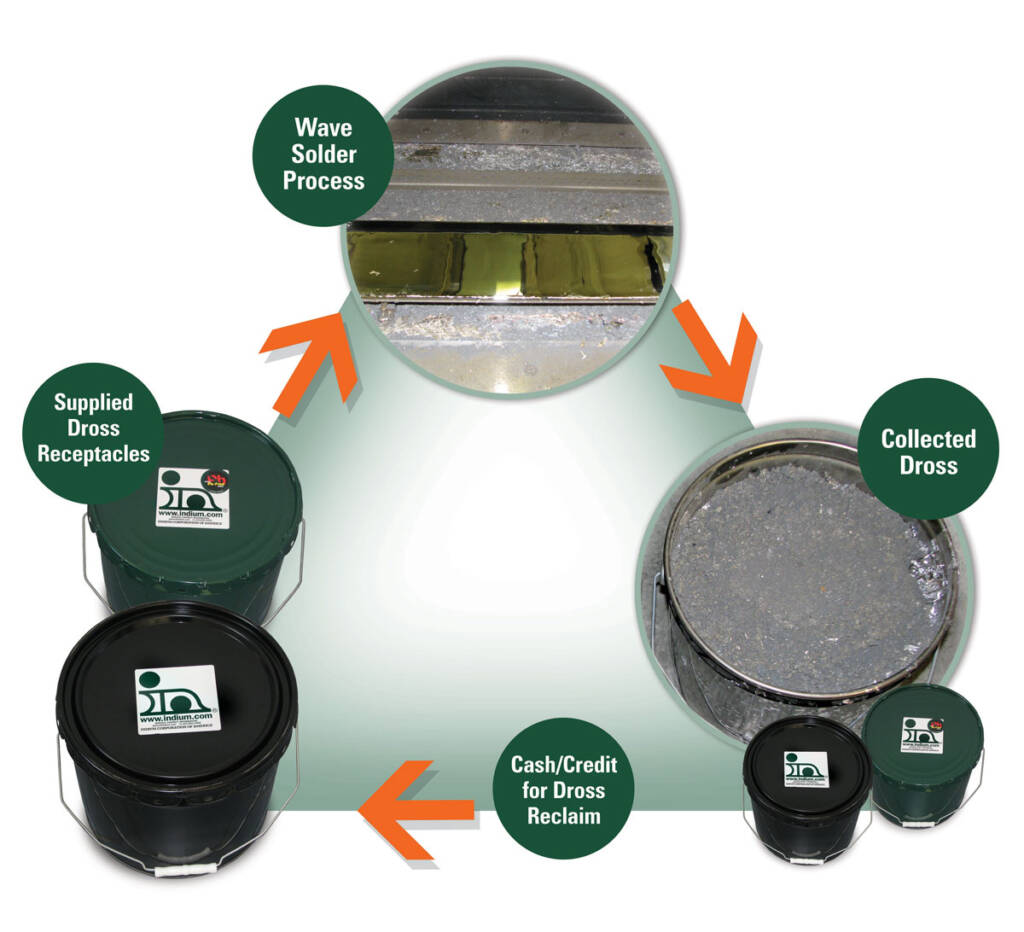

Wave Flux

Indium Corporation offers a full line of competitive, state-of-the-art wave solder fluxes for electronics assembly. We were the first company to introduce halogen-free, Pb-free wave fluxes that perform as well as the more established halogen-containing tin-lead wave fluxes.

Powered by Indium Corporation

- Wide Variety of Options

- Compatible with Pb & Pb-Free

- High Reliability

Product Overview

All wave solder fluxes are available in 55-gallon (200 liter), 5-gallon, and 1-gallon containers.

Wave fluxes include:

Wave Flux Products

Alcohol-based

The main advantage of alcohol-based fluxes is that they require less preheat to drive off the solvent prior to entering the wave. This allows assemblers to run smaller wave soldering machines at a higher throughput rate.

It also reduces the concern about flux that has not been completely heated inadvertently transferring to the top side of the circuit board. Fluxes that have high solids content, as well as higher amounts of halogen, tend to be more heat-stable and solder better with a variety of board types, sizes, and thicknesses. Fluxes with lower solids contents and no rosin tend to be easier to electronically probe-test and have less visually apparent residue. Halogen content is not necessarily an indicator of final circuit board reliability since halogen types vary and rosin in the flux will enhance an assembly’s surface insulation resistance.

| Flux | Classification 004A | 004B | pH | Specific Gravity (@25°C) | Solids Content | Halide | Halogen Content | Rosin/Resin | Acid Value | Tin/Lead Pb-Free | Application | Shelf Life | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WF-9940* | ROL0 | 4.6 | 0.795 | 3.63 | No | Yes | 18.0 | 16-3000 | Foam/Spray | 2 Years | ||

| WF-9942* | ORL0 | 4.0 | 0.828 | 4.37 | No | No | 36.0 | 16-3000 | Foam/Spray | 2 Years | ||

| WF-9945* | ROL0 | 5.8 | 0.796 | 5.77 | No | <50ppm | Yes | 14.4 | 16-3000 | Foam/Spray | 2 Years | |

| WF-9948* | ROL0 | 5.5 | 0.792 | 3.27 | No | <900ppm | Yes | 14.9 | 16-3000 | Foam/Spray | 2 Years | |

| WF-9955 | ORL0 | 6.5 | 0.796 | 4.71 | No | <50ppm | Yes | 26.3 | 16-3000 | Foam/Spray | 2 Years | |

| WF-9958 | ORMO | 4.2 | 0.798 | 4.99 | No | <50ppm | No | 28.5 | 16-3000 | Foam/Spray | 2 Years | |

| WF-9946-NP | ROL0 | 5.9 | 0.815 | 5.22 | No | <50ppm | Yes | 20.6 | 16-3000 | Foam/Spray | 2 Years | |

| 3541 | ORL0 | N/A | 0.800 | 4.31 | No | Yes | 25.0 | 16-3000 | Foam/Spray | 2 Years | ||

| 3545 (FP500) | ROL0 | ROL0 | 6.0 | 0.812 | 11.25 | No | <50ppm | Yes | 29.5 | 16-3000 | Foam/Spray | 3 Years |

| 3577-TF | ORL0 | 7.0 | 0.797 | 4.0 | No | Yes | 17.0 | 16-3000 | Foam/Spray | 2 Years | ||

| 3590-T | ORL0 | 3.2 | 0.803 | 1.85 | No | No | 16.0 | 16-3000 | Foam/Spray | 2 Years | ||

| 3590-TX | ORL0 | 3.2 | 0.809 | 2.50 | No | No | 22.0 | 16-3000 | Foam/Spray | 2 Years | ||

| 3592 | ORL0 | 4.0 | 0.820 | 2.64 | No | No | 22.0 | 16-3000 | Foam/Spray | 2 Years | ||

| NR10D | ORL0 | 4.8 | 0.791 | 1.38 | No | No | 12.0 | 16-3000 | Spray | 2 Years | ||

*= Primary Formulas

Fluxes are available in 1-gallon and 5-gallon containers, and 55-gallon drums.

VOC-free

VOC-free fluxes use water as the dominant solvent.

In addition to limiting the amount of volatile organic compounds (VOC) into the atmosphere, sometimes associated with global warming, VOC-free fluxes are also non-flammable. The disadvantage of VOC-free/water-based fluxes is that they require more pre-heat to drive off the water than similar alcohol-based fluxes. In addition, assemblers must be careful to ensure that the top side of the circuit board is dry, otherwise it could lead to reliability issues in the form of electromigration.

| Flux | Classification 004A | 004B | pH | Specific Gravity (@25°C) | Solids Content | Halide | Rosin/Resin | Acid Value | Tin/Lead Pb-Free | Application |

|---|---|---|---|---|---|---|---|---|---|

| WF-7742* | ORL0 | 3.2 | 1.014 | 5.76 | No | No | 36.0 | Both | Spray |

| WF-7745 | ORL0 | 2.8 | 1.013 | 4.22 | No | No | 36.0 | Both | Spray |

| 1072 | ORL0 | 7.0 | 1.018 | 6.62 | No | Yes | 25.0 | Both | Spray |

| 1075 | ORL0 | 2.8 | 1.008 | 1.91 | No | No | 20.0 | SnPb | Spray |

| 1075-2 | ORL0 | 2.6 | 1.015 | 3.80 | No | No | 40.0 | Both | Spray |

| 1075-EX | ORL0 | 2.8 | 1.011 | 2.40 | No | No | 20.0 | Both | Spray |

| 1075-EX 30 | ORL0 | 2.8 | 1.014 | 2.70 | No | No | 30.0 | Both | Spray |

| 1075-EXR 30 | ORL0 | 2.8 | 1.015 | 3.71 | No | Yes | 30.0 | Both | Spray |

| 1075-EXR 40 | ORL0 | 2.8 | 1.021 | 6.23 | No | Yes | 40.0 | Both | Spray |

| 1075-EXR 44 | ORL0 | 2.8 | 1.021 | 6.23 | No | Yes | 40.0 | Both | Spray |

| 1076-30 | ORL0 | 2.8 | 1.014 | 2.85 | No | No | 30.0 | Both | Spray |

*= Primary Formulas

Fluxes are available in 1-gallon and 5-gallon containers, and 55-gallon drums.

Water-wash

Before no-clean fluxes became the most commonly used materials in wave soldering, water wash fluxes had an extended run as the preferred material.

The advantage of water wash fluxes is that they can be formulated to be very active so that they can solder virtually any assembly without a concern for reliability, since the residue will be removed after the soldering process. The disadvantage of water wash fluxes is that assemblers must have an additional piece of equipment, the water wash system, to remove the flux residue, and must deal with the effluent. Neutral pH fluxes can generally be left on the circuit board for extended periods of time before washing, while the “low” pH fluxes generally solder somewhat better.

| Flux | Classification 004A | 004B | pH | Specific Gravity (@25°C) | Solids Content | Halide | Halogen Content | Rosin/Resin | Acid Value | Value Tin/Lead Pb-Free | Application | Shelf Life |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1082* | ORH0 | 7.0 | 0.920 | 14.46 | No | <50ppm | No | Not Tested | Both | Foam/Spray | 2 Years |

| 1081 | ORH0 | 5.0 | 0.957 | 28.44 | No | <50ppm | No | Not Tested | Both | Foam/Spray | 2 Years |

| 1081-T | ORH0 | 5.0 | 0.908 | 12.57 | No | <50ppm | No | Not Tested | Both | Foam/Spray | 2 Years |

| 1085 | ORH0 | 4.0 | 0.862 | 12.36 | No | <50ppm | No | Not Tested | Both | Foam/Spray | 2 Years |

| 1095NF | ORH1 | 6.5 | 0.839 | 19.52 | Yes | <4.50% | No | 34.0 | Both | Foam/Spray | 3 Years |

| 1010 | ORH1 | <2.0 | 1.055 | 20.96 | Yes | ~4.50% | No | 130.0 | Both | Spray | 2 Years |

*= Primary Formulas

Fluxes are available in 1-gallon and 5-gallon containers, and 55-gallon drums.

Rosin-based

The original fluxes for electronics assembly were rosin-based. Prior to the IPC’s J-STD-004(b), the defense electronics industry established specifications for fluxes.

To this day, some contracts still exist that require fluxes that conform to the old Mil-Spec Mil-F-14256 or QQ-S-571 as a type R, RMA, or RA, even though these specifications have officially been folded into the J-Standard. Rosin-based fluxes were popular because not only is rosin a natural weak flux when molten, but it is also a good dielectric material when solid. Small amounts of residue left on the assembly generally will not harm the assembly unless it operates at high temperature and humidity.

| Formula | Acid # | Solids % | J-STD-004 | J-STD-004B | Halogen | Apply | Description |

|---|---|---|---|---|---|---|---|

| 2036 | 50 | 36.42% | ROL0 | ROL0 | <50ppm | Foam | Rosin Type “R”, ROL0 |

| 2212 | 38 | 25% | ROL1 | ROL1 | <0.15% | Foam | Rosin Type “RMA”, ROL1 |

Fluxes are available in 1-gallon and 5-gallon containers, and 55-gallon drums.

Related Applications

Related Markets

Product Data Sheets

WS-9942-1 Wave Solder Flux PDS 99661 R0.pdf

WS-446HF Flux PDS 99718 R2.pdf

WF-9948 Wave Solder Flux PDS 98829 R8.pdf

WF-9955 Wave Solder Flux PDS 98689 R3.pdf

Looking for Safety Data Sheets?

Access everything you need — from technical specifications to application guidance — in one convenient location.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.