Applications

Semiconductor Packaging and Assembly

As semiconductor packaging technologies evolve to meet industry demands of smaller, faster, higher power, more reliable, more efficient devices, packaging and assembly materials play a crucial role. From industry leading die attach solder pastes, ultra-fine solder pastes for SiP, to innovative flux technology for flip-chip bonding and BGA ball attach. Indium Corporation’s semiconductor packaging and assembly materials address todays challenges and help power the future.

Overview

Semiconductor packaging and assembly are critical to manufacturing semiconductor devices, ensuring functionality, efficiency, and reliability. This back-end-of-line (BEOL) process involves encapsulating the silicon die or integrated circuit (IC) to ensure reliable electrical connections to the PCB and other systems. It’s essential for maintaining functionality and durability in diverse environments. Indium Corporation’s expertise in these processes and product selection meets the unique needs of the industry.

Benefits

Proven Materials

Indium Corporation’s advanced products have been integral in the advancement of semiconductor assembly. Our wafer bumping flux WS-3401 and flip-chip flux WS-641 are widely used in 2.5D and advanced semiconductor assembly.

Leading the Way

Over a decade ago, Indium Corporation introduced the first ultra-low residue flux and has remained a pioneer in the field, offering a diverse range of ultra-low residue fluxes.

SiPaste®3.2HF

For over a decade, true washable SiPaste®3.2HF has been the preferred choice for millions of SiP modules.

Fluxless

Through collaboration with industry leaders, we have developed a fluxless adhesive solution for advanced flip chip attachment.

20 Years

With over 20 years of proven performance, our SMQ75 high-temperature high Pb paste remains the industry standard for die-attach on leadframe applications.

High-temperature Pb-free

We’re proud to introduce Durafuse® HT, a drop-in Pb-free solution for replacing Pb-containing solders in high-temperature applications.

5 Billion

To date, over 5 billion front-end SiP modules have been manufactured using Indium Corporation’s semiconductor materials, with continuous growth expected.

Sustainability

These fluxes enable a true no-clean process, driving sustainability by reducing costs related to cleaning chemicals, water, and energy consumption.

Essential Considerations in Semiconductor Packaging & Assembly

Semiconductor assembly involves the process of packaging and interconnecting semiconductor chips or integrated circuits onto a substrate to create functional electronic devices. Semiconductor packaging involves these key considerations:

Interconnect Reliability

Ensuring robust electrical connections to minimize signal loss and resistance.

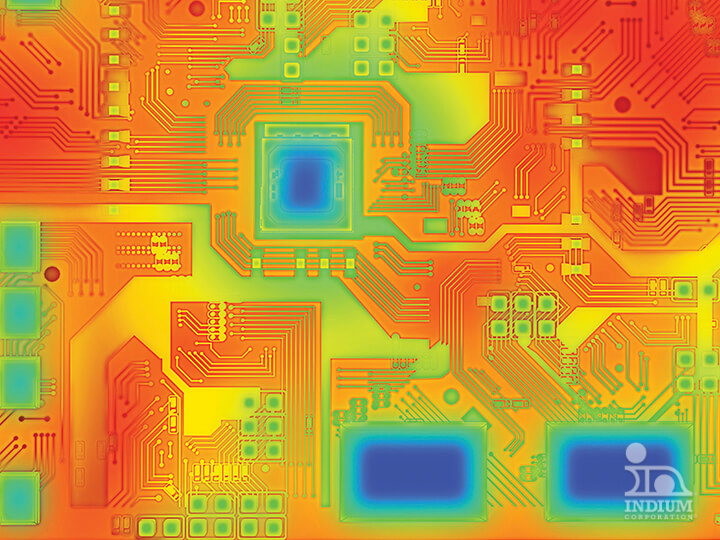

Thermal Management

Implementing efficient heat dissipation solutions to prevent overheating and maintain device performance.

Material Compatability

Selecting packaging materials with compatible coefficients of thermal expansion (CTE) to reduce stress on interconnects and prevent mechanical failures due to thermal cycling.

Semiconductor Packaging & Assembly Products

Indium Corporation offers a full line of wave fluxes that can meet the needs of numerous selective soldering applications. For example, the WF-9948 flux is excellent for those applications where reliability and minimal post-soldering residues are required.

Related Markets

Mastering Solder Preform Technology With Low Temperature Solder Alloy Solutions

Achieving efficiency, reliability, and exceptional thermal performance is crucial in package-attach soldering applications for power modules. However, the high reflow temperatures required by

The Surge of Cu Sinter Paste

A little over a year ago, I posted about the increase in interest regarding Cu sintering. In the past 12 months, that interest has has surged, highlighting Cu sintering's suitability for various

Back to the Basics: Flux

During my first few weeks as a Technical Support Engineer at Indium Corporation, Iresearched extensively and consulted with my team to find out when flux should be used and why it’s essential

Ramp-to-Peak: The First Thought in a Reflow Profile

Folks, I am working on a book with my Indium Corporation colleagues on tackling soldering defects in electronics.It is a follow up to our The Printed Circuits Assembler's Guide to Solder Defects.

From Scrap to Savings: Indium Corporation’s Commitment to a Sustainable World

In today's fast-paced world, where sustainability and environmental responsibility are paramount, Indium Corporation is leading the charge with an innovative approach to resource management. Our

Indium Sealing Materials

Folks, In today’s blog we will interview Pamela Nelson. She is a Product Specialist for Indium Corporation’s sealing Figure 1. Product Specialist Pamela Nelson of Indium Corporation.

Overview of InFORMS

Overview of InFORMS® In the world of electronics manufacturing, especially in high-stress applications like power modules and electric vehicle inverters, ensuring the reliability and durability

Improved IMC Growth Rate Calculator

Folks, Peter writes: Dear Dr. Ron, I amthrilled with your Excel® program to calculate IMC thickness as a function of time. However, I wanted to calculate IMC thickness for times not listed in the

Solder Paste is Not a Commodity

Folks, I was getting a little cabin fever, so I thought I would go for lunch at Simon Pearce. The ambiance there always relaxes and refreshes me. So, the maître de squeezed me in at a small

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.