Indium Corporation Prepared to Deliver Three Presentations at APEC 2024

February 6, 2024

As one of the leading materials providers to the power electronics assembly industry, three Indium Corporation team members will share their insights and knowledge on a variety of industry-related topics throughout APEC 2024, February 25-29, in Long Beach, CA.

Tuesday, February 27

- 1:30 p.m. – 2:00 p.m. PST

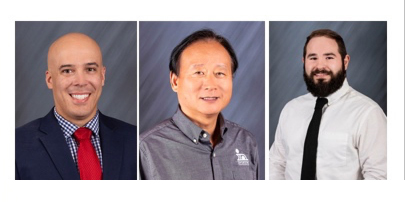

- Power Module Package-Attach Materials Technology by Product Manager – ESM/Power Electronics Joe Hertline

- Hertline will explore new innovations and trends in power module package-attach materials technology, including a novel Pb-free alloy that enables lower processing temperatures in preform soldering compared to SAC alloys. This alloy prevents warpage in package-cooler attach scenarios without sacrificing reliability like traditional bismuth-containing low-temperature alloys. Sintering applications and thermal interface materials trends will also be discussed.

Thursday, February 29

- 2:45 p.m. – 3:10 p.m. PST

- Material Considerations for Next Generation EV Inverter Architectures by Strategic Advisor Dongkai Shangguan

- Dr. Shangguan will focus on the unique challenges posed by 800V inverter architecture, a field growing in complexity with the increasing size of power electronics. Key issues will include design considerations, thermal management, and the selection of suitable materials. Particular emphasis is placed on the problems of warpage and delamination, which present notable manufacturing challenges and have critical implications for the reliability and safety of end-products.

- 2:50 p.m. – 3:10 p.m. PST

- Low-Temperature Pb-Free Solder Preform Technology for Molded Power Module Package Attach Designed for Improved Thermomechanical Performance by Senior Applications Development Engineer Ryan Mayberry

- Mayberry will examine a low-temperature Pb-free soldering solution for high power-density power electronics, addressing the trade-off between cost, complexity, and performance in thermal management/mechanical attach solutions for power modules. The proposed SAC-In alloy solution, in a solder preform configuration, has reflow temperatures below industry standard lead-free and high-temperature solders. It serves as a drop-in replacement, offering improved thermal performance compared to organic-based thermal management solutions, while mitigating risks of component damage, material stress, and reducing energy consumption with a peak reflow temperature below ~215°C. The Bi-free alloy also demonstrates robust lifecycle performance comparable to standard Pb-free alloys in thermal shock testing at -40°C/+125°C.

Hertline is responsible for driving the growth of the power electronics product line through development and implementation of marketing strategies supported by customer experience, emerging technologies, and industry feedback. Hertline also collaborates with Indium Corporation's sales, technical support, R&D, production, and quality teams to serve existing customers and grow new business in his designated market. He earned a bachelor's degree in mechanical engineering and an MBA from Clarkson University and is a Certified SMT Process Engineer (CSMTPE).

Dr. Shangguan is a Strategic Advisor to Indium Corporation. In this role, he works on specific trends related to the advanced semiconductor packaging and SMT industries, and applies his significant industry experience to supporting customers. Dr. Shangguan is an IEEE Fellow and IMAPS Fellow, and has served on the boards of directors for several professional organizations and industry associations, including IPC, IEEE EPS, and iNEMI. He also serves as a Distinguished Lecturer for IEEE EPS. He has been honored with some of the industry's most prestigious awards, including IPC's President's Award, the Society of Manufacturing Engineers' (SME) Total Excellence in Electronics Manufacturing Award, the Electronics Manufacturing Technology Award and the Outstanding Sustained Technical Contribution Award from IEEE EPS, and the William D. Ashman Achievement Award from IMAPS, among others. Dr. Shangguan received a bachelor's degree in mechanical engineering from Tsinghua University, China, an MBA from San Jose State University, Calif., and a Ph.D. in materials from the University of Oxford, U.K. He has held postdoctoral positions at the University of Cambridge, U.K., and the University of Alabama, and has served as a guest professor at several universities. Dr. Shangguan has published three books, more than 200 scientific papers and technical articles, and has given numerous presentations to share knowledge and expertise with the industry. He is the inventor/co-inventor of 33 U.S. patents and several foreign patents.

Mayberry is responsible for generating test strategies, data sets, and application guidelines for Indium Corporation's Engineered Solder Materials (ESM) product line. He collaborates with sales, R&D, operations, and quality departments as a subject matter expert to enable key pursuits in the power electronics and thermal market segments by developing process recommendations and supporting new product qualifications for a successful customer experience. Mayberry holds a bachelor's degree in materials science and engineering from Rutgers University, N.J. He is a Certified SMT Process Engineer (CSMTPE) and is certified as a Lean Six Sigma Green Belt.

To learn more about Indium Corporation's innovative products for EV and power electronics, visit us at booth #752 at APEC or online at indium.com.

About Indium Corporation

Indium Corporation® is a premier materials refiner, smelter, manufacturer, and supplier to the global electronics, semiconductor, thin-film, and thermal management markets. Products include solders and fluxes; brazes; thermal interface materials; sputtering targets; indium, gallium, germanium, and tin metals and inorganic compounds; and NanoFoil®. Founded in 1934, the company has global technical support and factories located in China, Germany, India, Malaysia, Singapore, South Korea, the United Kingdom, and the U.S.

For more information about Indium Corporation, visit www.indium.com or email Jingya Huang. You can also follow our experts, From One Engineer To Another® (#FOETA), at www.linkedin.com/company/indium-corporation/.