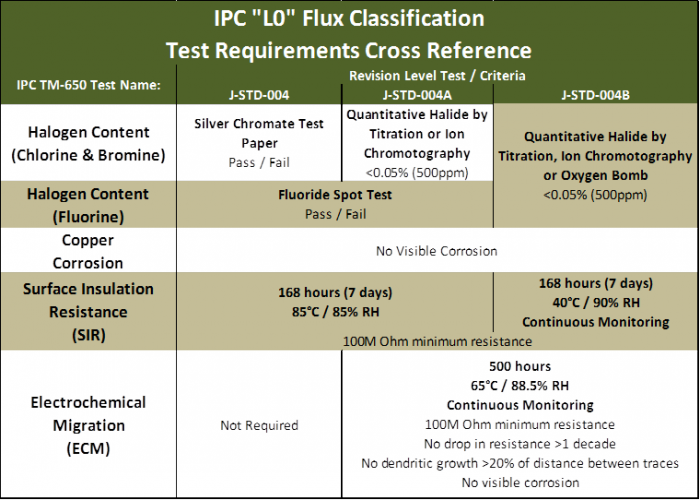

The IPC J-STD-004 specification is the standard by which most North American flux suppliers and electronics assembly companies categorize, test, and qualify their soldering flux. The -004 specification first emerged as a joint specification in 1995 with the lofty ambition of combining the requirements of the legacy MIL-specification, the telecommunication industry's Bellcore requirements, and the emerging IPC specifications for the more general electronics industry. It has been an ongoing cooperative work of EMS, OEM, and solder companies. However, that is not to say that the standard was perfect from the outset. It has evolved over the years to better reflect new needs, technologies, and understandings. Here is a summary of the evolution of the core classification tests:

J-STD-004 (1995)

Combined the MIL-F14256 tests: copper mirror, silver chromate test paper for bromides and chlorides, fluoride spot test with an industry-agreed-upon 7 day surface insulation reliability test, and a copper corrosion test.

J-STD-004A (2004)

Added a 500 hour electrochemical migration test and a quantitative titration (or ion chromatography) chloride and bromide halogen test in an attempt to better-define reliability risks.

J-STD-004B (2008)

This version plugged a couple of weaknesses in the halogen tests. The new quantitative method enhanced the ability to detect non-ionic halogenated compounds and lower levels of fluoride by first pyrolizing the flux sample in an oxygen bomb to decompose the non-ionic halogenated materials and then detecting the amount of free halide using ion chromatography. IF YOU HAVE STRICT HALOGEN-FREE REQUIREMENTS, IT IS VERY IMPORTANT THAT THE FLUX, PASTE, OR CORED WIRE YOU ARE USING HAS BEEN TESTED TO J-STD-004B TO ENSURE THAT IT HAS LESS THAN 500ppm TOTAL HALOGEN.

The surface insulation resistance (SIR) test was also changed to incorporate lower temperature, higher humidity, and lower voltages which has generally show to promote current leakage without quickly destroying dendrite formation.

SUMMARY

Overall we believe that while the J-STD-004B standard may not be perfect - and subject to future further evolution - it does provide the best available means of flux classification to date, and also provides for the greatest opportunity for ensuring flux-related final reliability. It is for this reason that the Indium Corporation has committed to developing, classifying, and qualifying all of its new and popular products to the J-STD-004B version, even though the IPC industry committee granted all solder manufacturers the option to not re-qualify their products to the latest version, once qualified to an older version. Even 7 years after the release of J-STD-004B, industry-wide you will still find many older wave flux, cored wire, and solder paste technical data sheets (including some legacy products from the Indium Corporation) referencing the older and less comprehensive J-STD-004 or J-STD-004A standards.