In my last post, NanoFoil Basics:Activation Part I, I talked about NanoFoil(r) activation properties(remember, I'm not using the term " ignition" because it implies burning, NanoFoil activation is more of a localized flash of heat), and some various ways to ignite the NanoFoil. To review a bit, the two easiest ways to ignite the NanoFoil are by thermal (a heat source) and electrical energy (a spark). Mechanical will work, but it requires a very concentrated impact which is very difficult to use or reproduce.

Don't Play Laser Tag with NanoFoil

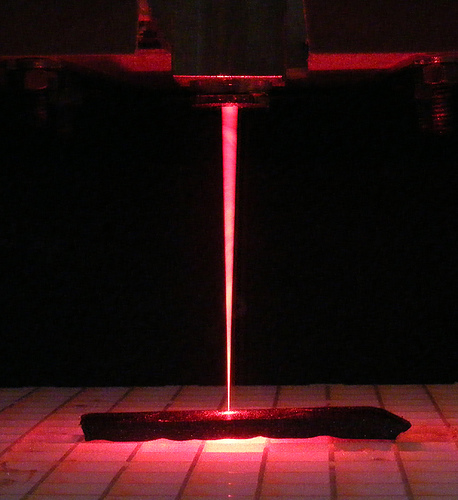

The last way to activate the NanoFoil is through the use of a laser. Now this makes sense right? A form of high energy, very localized can ignite the NanoFoil. Where it gets tricky is that a laser can also be used to cut NanoFoil as well! I won't go into the gory details here, but with tweaking of the pulse width and power, a laser can either cut through the NanoFoil to make intricate shapes OR it can ignite the NanoFoil. There are great processing implications for being able to ignite foil with a laser. In automation, for example, a laser could be built into a head fixture that simultaneously deposits the NanoFoil, appiles pressure and ignites. Additionally, having a through hole on the backside of a board where the component sits can give a sightline for activation with a laser.

Activation Tools

The easiest and cheapest way to ignite foil is with a 9 volt battery. By hooking up wires to the leads and touching both leads to the foil (essentially shorting the battery and generating heat) you can activate the NanoFoil. In demonstrations we have also forgone the leads and simply touched the leads of the 9Volt to the foil.

American Beauty – The most common small production level tool used by customers and here at Indium is the American Beauty resistance soldering tool. With this tool one lead can be grounded to a press or the part, and a secondary probe can be used to complete the circuit by touching the NanoFoil. Simple, easy, reliable and fits onto a table top, perfect for small scale manufacturing needs.

MPIS (Multi Point Ignition System) – Primarily used for sputtering target bonding with NanoFoil. For sputtering targets larger than 6 inches, the NanoFoil needs to be activated in multiple  locations to reduce voiding. This needs a full blog post to explain the in-depth details, but the basics are as follows: when the NanoFoil is activated under pressure between two layers of solder, at the wave front of the NanoFoil is molten solder. If the NanoFoil is activated at one location for a large part, the wavefront of molten solder will spray out the opposite side of the activation causing voiding. If instead the NanoFoil is activated at opposite points around the part, the wavefront of molten solder meets in the middle and causes minimal to no voiding.

locations to reduce voiding. This needs a full blog post to explain the in-depth details, but the basics are as follows: when the NanoFoil is activated under pressure between two layers of solder, at the wave front of the NanoFoil is molten solder. If the NanoFoil is activated at one location for a large part, the wavefront of molten solder will spray out the opposite side of the activation causing voiding. If instead the NanoFoil is activated at opposite points around the part, the wavefront of molten solder meets in the middle and causes minimal to no voiding.

ESD Sensitivity

A lot of times we get asked: is the NanoFoil ESD sensitive?It is a logical question, with a reactive material that last thing you want is an operator shocking the NanoFoil and activating it. We have had the NanoFoil sent through standard ESD question, and the company responded in true engineering fashion:"The operator would have to have enough electrostatic energy running through him to kill him 10 times over before the NanoFoil would go off" And so the short answer is no, the NanoFoil is not susceptible to ESD!